Advanced 3D printing and manufacturing technology can produce flexible machines that will save countless lives in the future. Not only can they be used for search and rescue software robots, but they can also provide temporary organs for people on the mobile waiting list, and the ETH Zurich research team manufactures and tests artificial hearts. The researchers used a 3D printing technique and lost wax casting technology to create a silicone heart, like a real organ.

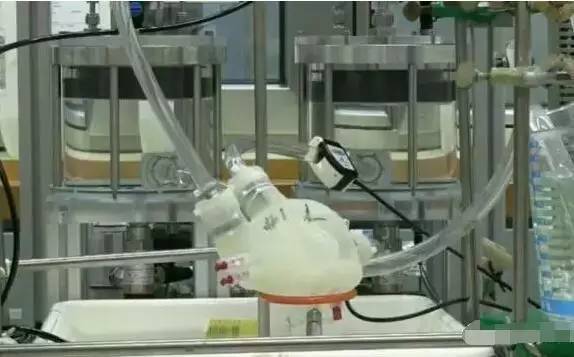

ETH Zurich's functional materials engineering prof. Wendelin Stark led the project. Create a heart mold using Siemens CAD software and create a silicone heart using 3D printing, lost wax casting technology, weighing nearly 400 grams; Stratasys uPrint SE Plus and HP Designjet 3D are used for actual 3D printing. It looks like a real heart with a left ventricle and a right ventricle; separated by a chamber that acts as an organ muscle. When the chamber is inflated and deflated by pressurized air, the pump pumps liquid out of the chamber.

PhD student Nicholas Cohrs said: "It is a silica gel with a complex internal structure."

Pressurized air is used to inflate and deflate the artificial heart, which is needed to draw fluid from the blood chamber - this behavior replaces the muscle contraction of a real human heart. This is the goal of the project - to imitate a real heart as much as possible. Conventionally manufactured blood pumps can cause problems because mechanical components can suffer complications when the patient has no physiological pulses.

Cohrs explained: "Therefore, our goal is to develop an artificial heart of roughly the same size as the patient itself, and to mimic the human heart as much as possible in form and function."

The research team published their experimental results in Artificial Organs entitled A Soft Total Artificial Heart-First Concept Evaluation on a Hybrid Mock Circulation. Co-authors include Cohrs, Meboldt and Stark, and Marianne Schmid Daners, Volkmar Falk, A. Xavier Kohll, Michael Loepfe, Anastasios Petrou, Christoph M. Schumacher, Christoph T. Starck and Maria Yliruka.

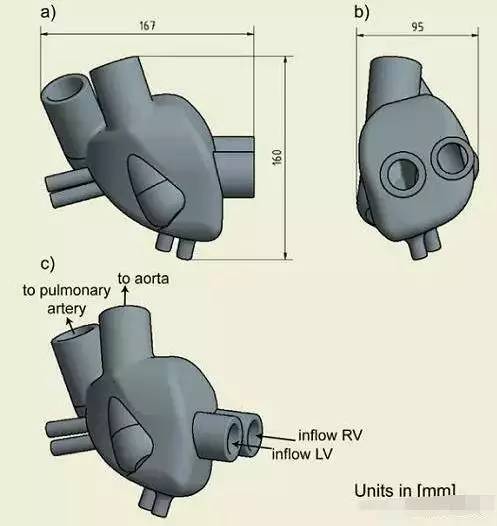

A sketch of a soft artificial heart in millimeters.

c) depicts the flow direction to the right ventricle (RV) and left ventricle (LV).

The team was able to prove that the 3D printed artificial heart works and moves like a real heart. When testing the device, the researchers used a liquid with a viscosity similar to human blood and found it to function in a similar way to the human heart. However, at present, the soft heart can only continue to beat about 3,000 times, which is equal to less than an hour (about 30-45 minutes), after which the material can no longer be under pressure. But this does not seem to bother the researchers.

“This is just a feasibility test,” Cohrs explained, "Our goal is not to prepare for the implantation of the heart, but to consider the new direction of artificial heart development."

_______________________________________________________

Paper link: http://onlinelibrary.wiley.com/doi/10.1111/aor.12956/full

Article source: Polymer Materials

Disclaimer: Some of the information comes from the Internet. The purpose of reprinting is to convey and share more information. It does not mean agreeing with its views or confirming its authenticity, nor does it constitute other suggestions. Only provide communication platform, not responsible for its copyright. If infringement is involved, please contact us to modify or delete it in time.

Email: echo@qingzitech.com