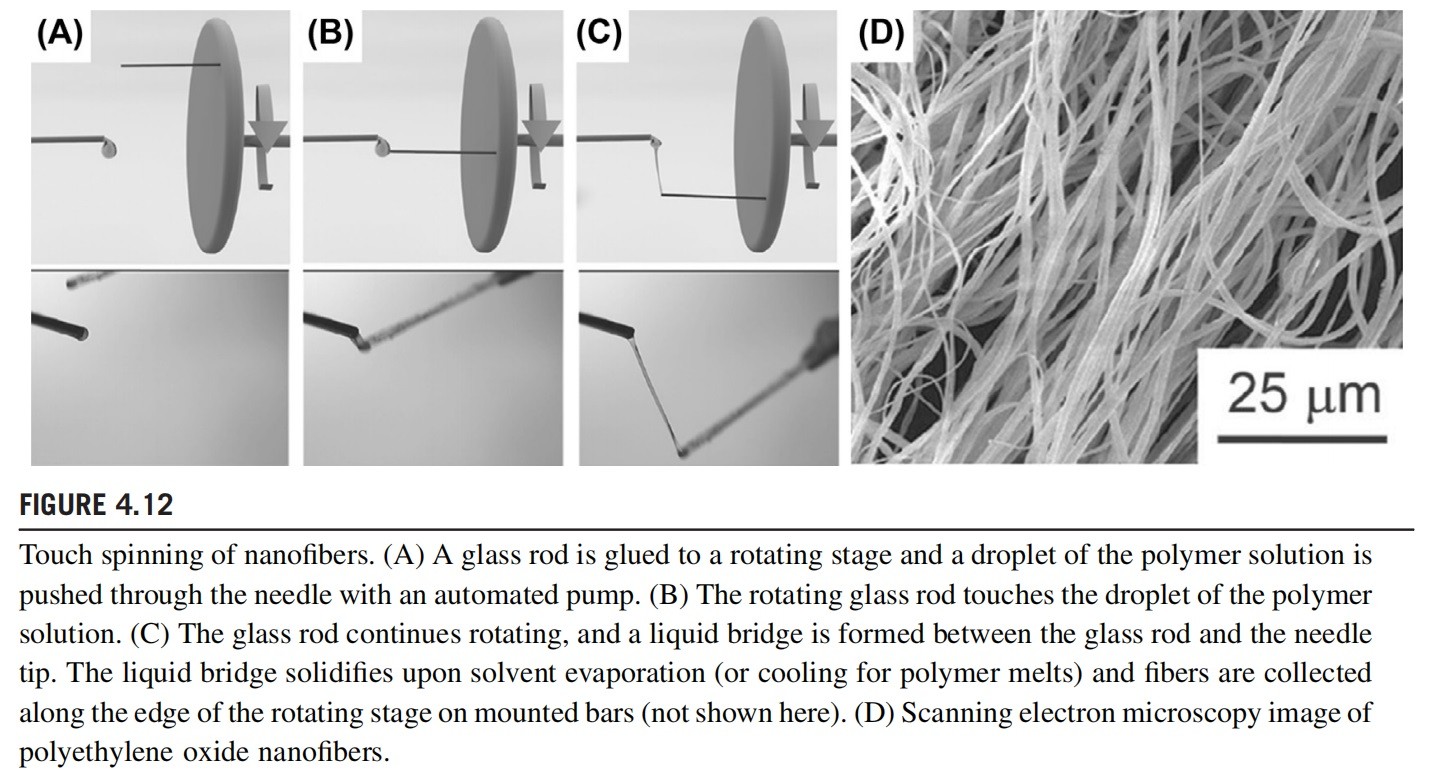

A further modification is a scalable method called touch spinning (Fig. 4.12). Nano/microfibers from 40 nm to 5 mm in diameter can be made by adjusting the rotational speed and polymer concentration (Tokarev et al., 2015). A glass rod (0.3 mm to a few millimeters in diameter) is glued to a rotating stage. A polymer solution is supplied, for example, from the needle of a syringe pump that faces the glass rod. The distance between the droplet of polymer solution and the tip of the glass rod is adjusted so that the glass rod contacts the polymer droplet as it rotates. Following the initial “touch,” the polymer droplet forms a liquid bridge. As the stage rotates, the bridge stretches and fiber length increases, with the diameter decreasing owing to mass conservation. Polyethylene nanofibers can be made by this method.