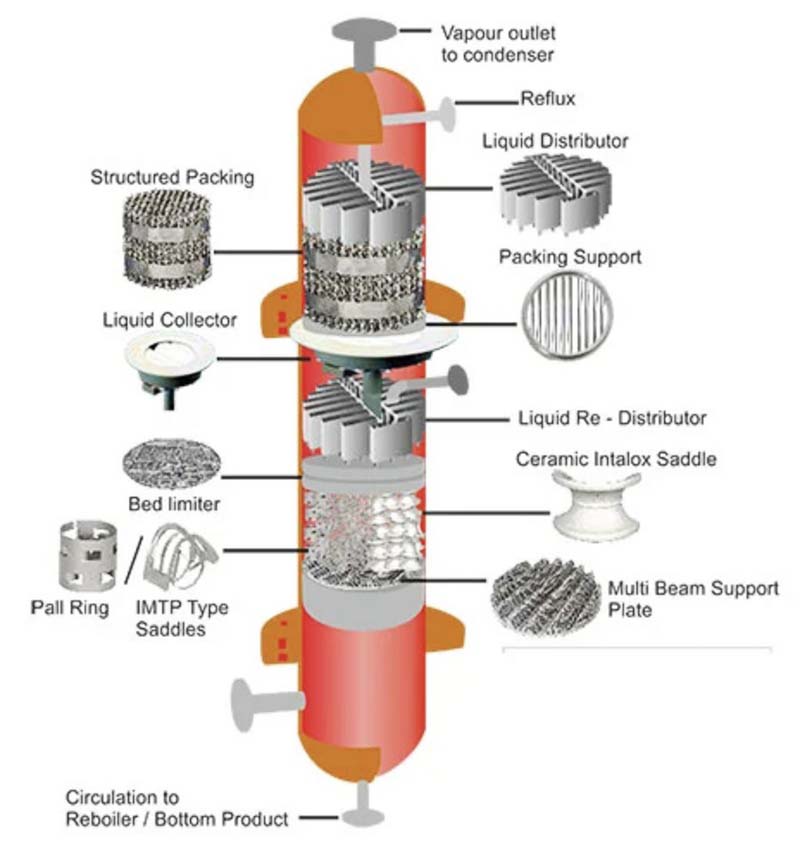

The packed column used for the separation of distillation is a vertical cylindrical vessel containing an appropriate packing bed supported and irrigated by the liquid flowing through a particular distributor. The bed height is determined by the packing mass transfers capacity and constrained are governed by allowable pressure drop and the overall column height.

For standard mass-transfer operations, packing can be considered as an alternative to conventional trays. However packing is more sensitive to fouling problems than trays and special attention for distributors at design step is required.

Packing could be a good solution for revamping units where extra capacity, energy savings or higher purity products are required.

The highest debottlenecking capacity can be achieved using structured packing for vacuum to medium pressure towers, even compared with high efficiency trays .

Tower packing can be provided in two different ways : random or structured.

The Random packing is made of small objects of typical sizes ranging from ½ in to 3 inches and dumped randomly in one or several beds in the towers.

The Structured packing is manufactured from metal sheets and assemblied in sections to fit with the tower inner diameter.

Packing performance is strongly related to liquid and vapor distribution quality,. it is highly recommended that distributor design is not under-estimated, the best being that each distributor is flow tested before shipment.