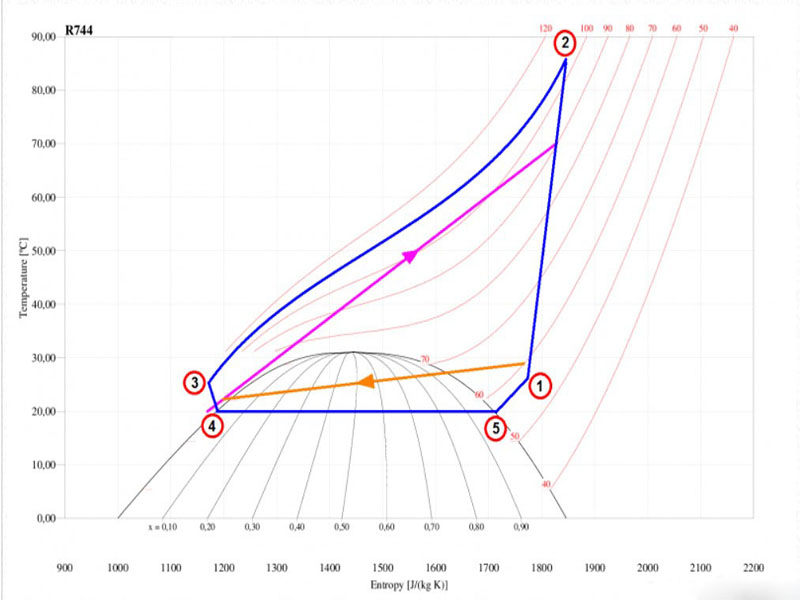

Above 31 °C, CO2 is transcritical. For transcritical CO2, heat intake at the evaporator takes place below the critical pressure of 71 bar. The release of heat within the gas cooler takes place above the critical pressure of 71 bar. Due to this, heat is released over a temperature range. This is in contrast with conventional compressor systems where heat release takes place at a fixed temperature. Therefore we talk about a gas cooler instead of a condenser; the refrigerant will not condensate, it is only cooled. The figure below shows the T-s diagram of a transcritical heat pump cycle with the refrigerant CO2. A waste water flow (orange) is cooled in the evaporator from 28 °C to 23 °C and process water (pink) is heated in the gas cooler from 20 °C to 70 °C. The red lines are lines of constant pressure.

The blue line represents the transcritical heat pump cycle. The steps in the cycle are:

1 - 2 Compression to transcritical pressure

2 - 3 Gas cooling in transcritical area, to heat process water

3 - 4 Expansion to low pressure

4 - 5 Evaporation by cooling down the waste water flow

5 - 1 Superheating in evaporator

The efficiency of a transcritical heat pump

The efficiency of a heat pump is given by a COP. The COP of a heat pump is usually calculated using the evaporation temperature and the condensation temperature. However, a transcritical heat pump has no condensation temperature, but a temperature range in the gas cooler. To calculate the COP, we have to use the mean temperature (Tm) in this temperature range. This mean temperature is calculated using the temperature at the inlet of the gas cooler (point 2) and the temperature at the outlet of the gas cooler (point 3). Read more about this.

Advantages CO2 transcritical heat pump:

For a high temperature lift at the side of the gascooler (at least 30-40 °C) and a low temperature of the water that needs to be heated, the efficiency of a CO2 transcritical heat pump can be higher than conventional heat pumps.

Disadvantages CO2 transcritical heat pump:

The temperature of the water that needs to be heated has to be low enough to make an efficient heat pump. When the CO2 is not cooled far enough due to the water flowing in, the process will not be efficient. In this situation an Ammonia heat pump is a better solution.

The system works with high refrigerant pressures of more than 100 bar.

Remark:

Some of the articles are taken from the Internet. If there is any infringement, please contact us to delete it. If you’re interesting in heat pump products,please feel free to contact OSB heat pump.