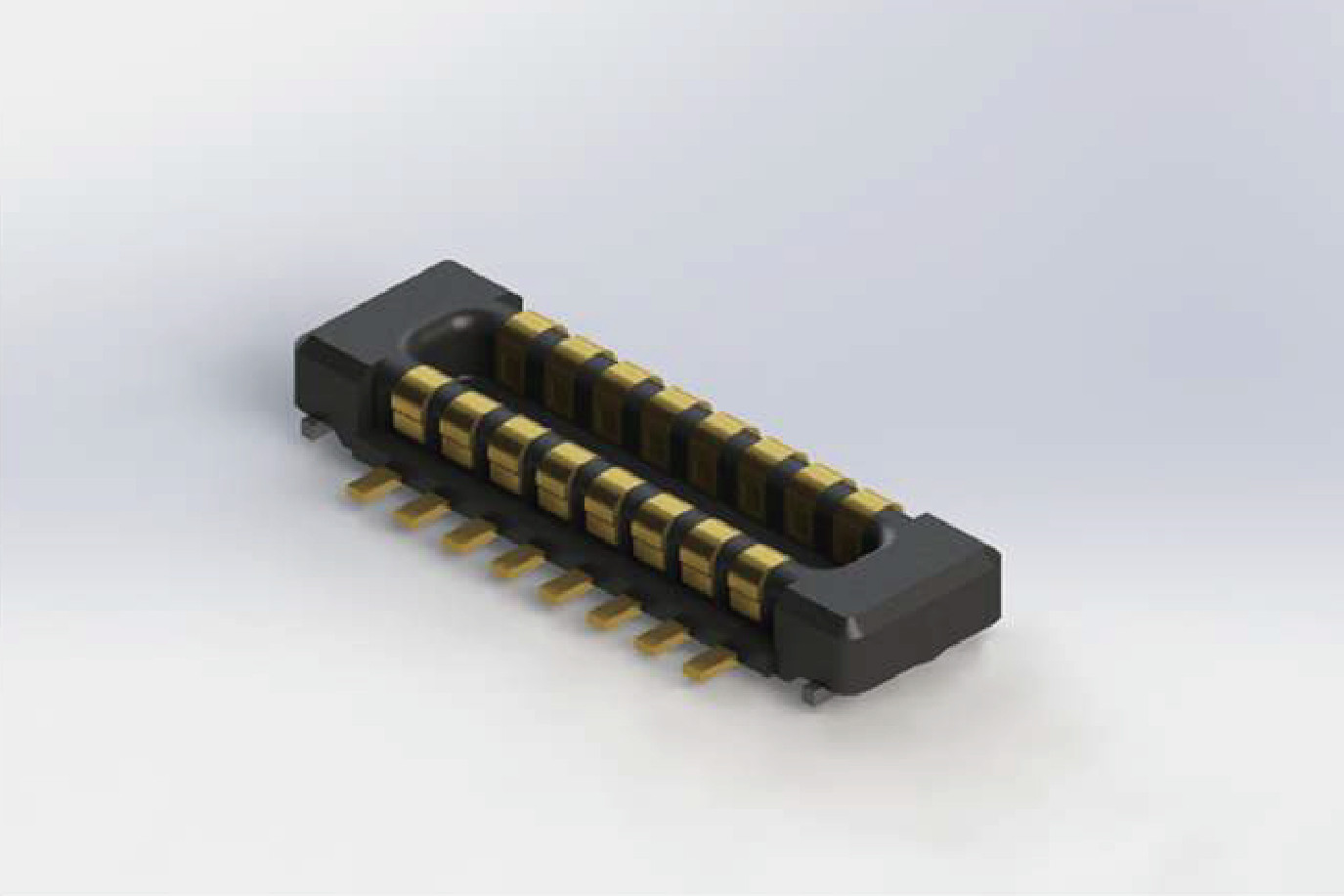

BTB connector is a product type of connector. Compared with other types of electronic connectors, BTB connectors not only have the strongest transmission capability, but also have the characteristics of light and thin, stable high-frequency transmission, no need for welding, noise reduction, etc. In terms of performance, the BTB connector has super corrosion resistance and excellent environmental resistance. It not only has the advantages of flexible connection, but also bears the signal conversion function. As a bridge between electronic components, the performance is very good.

When choosing a BTB connector, you can start with the number of pins, pitch value, and basic performance, such as electrical performance, environmental performance, and mechanical performance.

The number of pins and pitch value of the BTB connector is the basic basis for selection. The number of pins can be selected according to the number of signals to be connected. The BTB connector used in the field of consumer electronics is becoming more and more small pitch; BTB connection The electrical performance of the device is mainly reflected in four aspects, contact resistance, insulation resistance, limiting current and electrical strength. When switching on a high-power power supply, you need to pay attention to the limiting current of the BTB connector. When transmitting high-frequency signals, It is necessary to pay attention to the contact resistance; the environmental performance of BTB connectors includes temperature and humidity resistance, salt spray resistance, thermal shock, etc., depending on the application environment, the requirements for BTB connectors are also focused; the mechanical properties of BTB connectors are Refers to pull-out force, mechanical foolproofness, vibration, terminal retention force, etc.

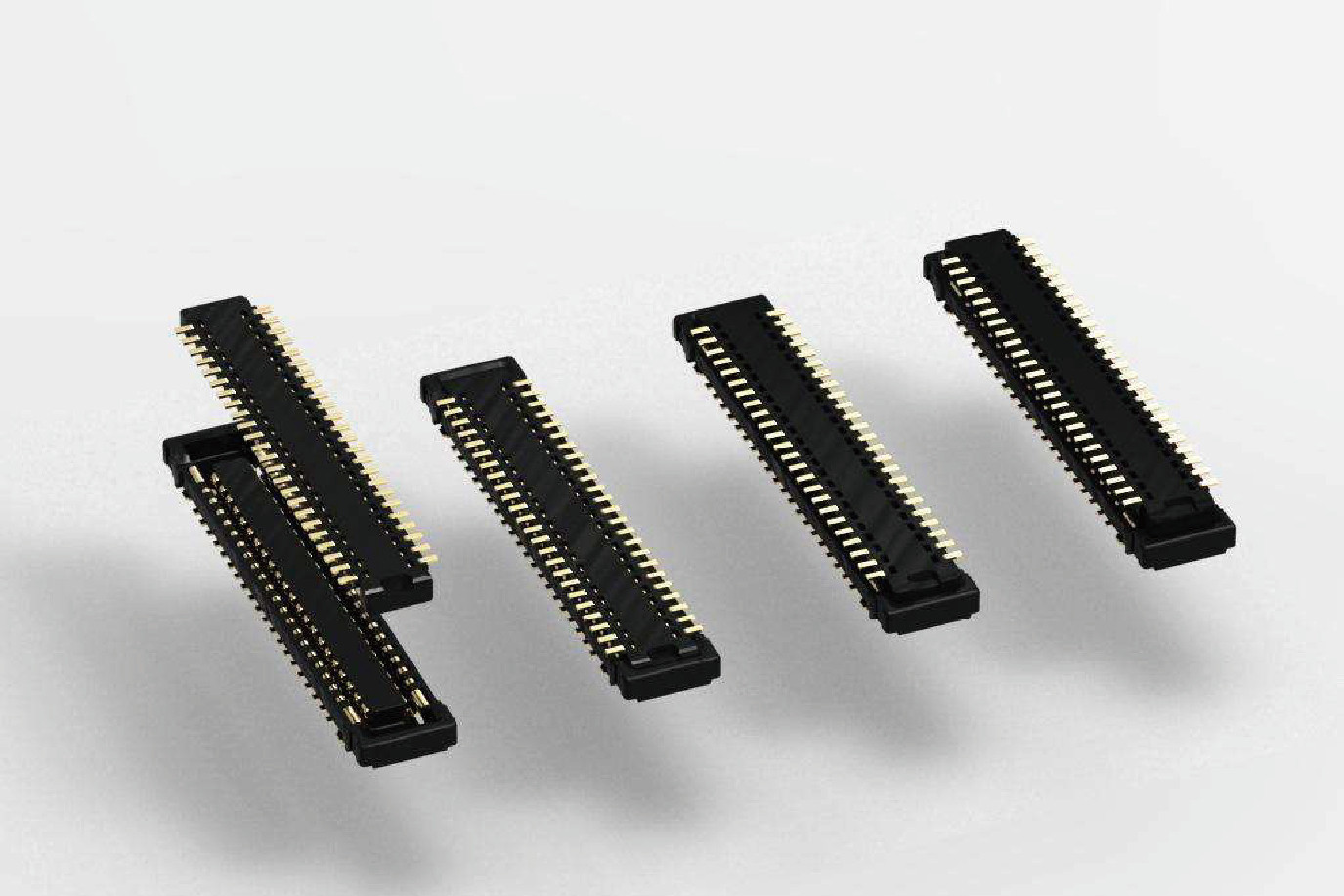

BTB connectors perform differently in different application areas. Under the development of 5G ecology, the demand for BTB connectors in smartphones is constantly increasing. In connection, a strong connection, a highly reliable connection, high-speed transmission, and anti-jamming capabilities must be achieved; in structural design, ultra-low height And precision, miniaturization, ultra-thin.

The smart phone BTB connector is mainly based on the narrow pitch. Its advantages of high performance, high precision and small size are in line with the current trend of ultra-thin and high-performance smart phones. In the future, BTB connectors will not only be optimized in terms of shape and structure, but will also have a major breakthrough in performance. With the development of digital and wireless technologies, BTB connectors will also be converted from traditional connection methods to wireless transmission. The small and precise BTB connector can achieve higher safety performance. In addition to high-speed transmission, it also converts electrical signals into optical signals and has a shielding function.

With the advent of the 5G era and the increase in the number of smart phone function modules, the demand for BTB connectors has continued to increase, and the production capacity of BTB connectors has risen, which has entered a rising cycle to a certain extent. From a comprehensive point of view of performance and market demand, BTB connectors can be said to have huge market space and penetration, and the fields that can be involved in the future are broader.

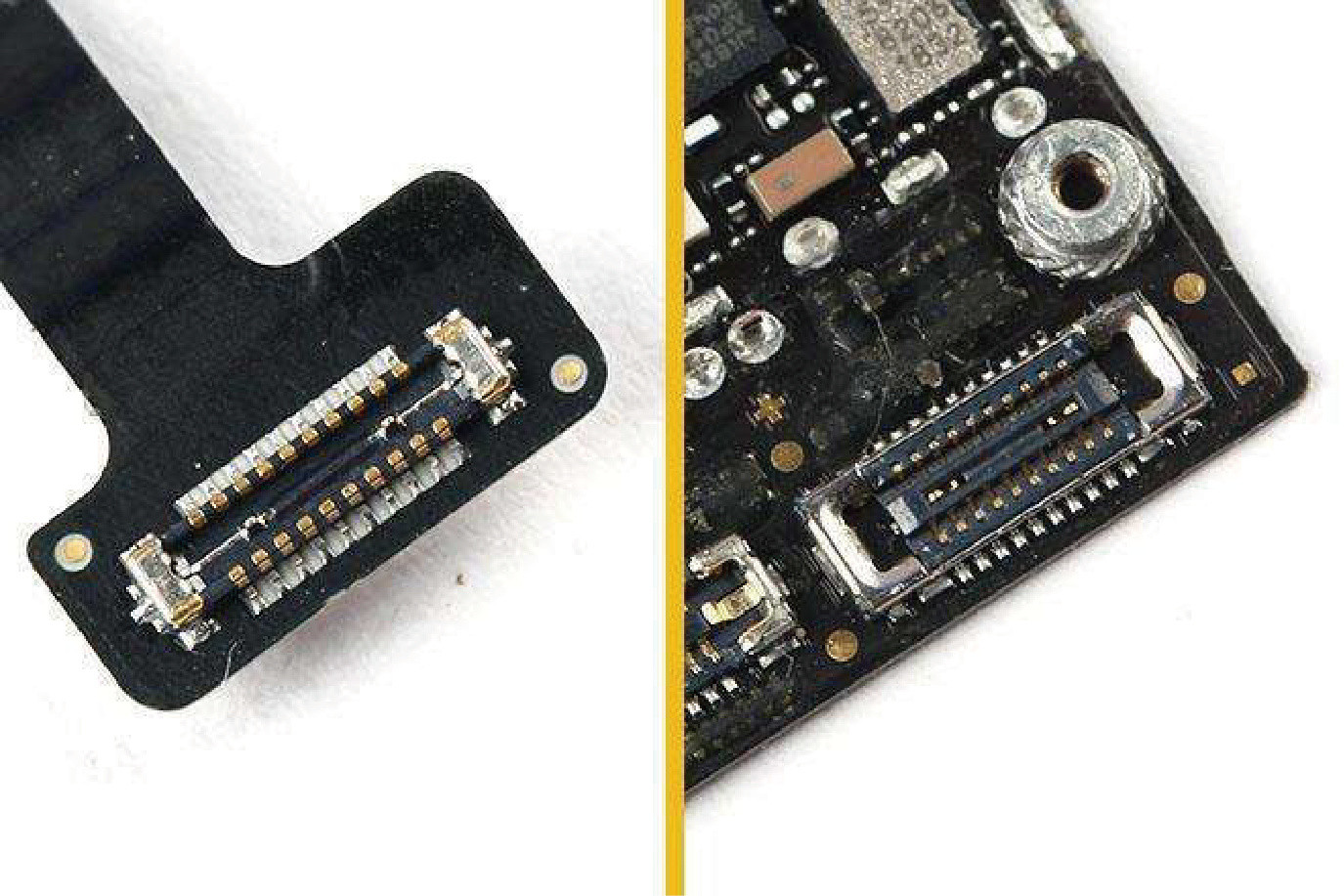

For the BTB connector test, the connector supplier has developed a module specifically for the BTB connector test-shrapnel microneedle module. This module supports small pitch contact modules and large current conduction modules in BTB connector testing. The minimum spacing value can reach 0.15mm, and the maximum current range can reach 50A.

The high-current shrapnel microneedle module is an integrally formed shrapnel design, which can stably connect the male and female seats in the BTB connector test. Different types of shrapnel have different application modes when testing BTB connectors.

1. Connect the zigzag-shaped shrapnel to the male seat of the BTB connector. During the test, the shrapnel of the shrapnel microneedle module contacts the top of the shrapnel of the BTB connector at multiple points to ensure the stability of the contact.

2. Use the pointed tip shrapnel for the BTB connector female seat. During the test, the shrapnel head is inserted between the shrapnel openings in the BTB connector to generate a certain amount of opening for the BTB connector to make the shrapnel contact surface Keep contact with the BTB connector shrapnel on both sides to ensure the stability of the test.

The self-cleaning capability design of the shrapnel micro-needle module head type eliminates the time and material cost of manual maintenance, and can maintain the long-term stability of the BTB connector test. The material of the shrapnel microneedle module is nickel alloy / beryllium copper, which has the characteristics of high precision and durable wear resistance. The mechanical life is up to 20w times, which can effectively improve the test efficiency and reduce the test cost.