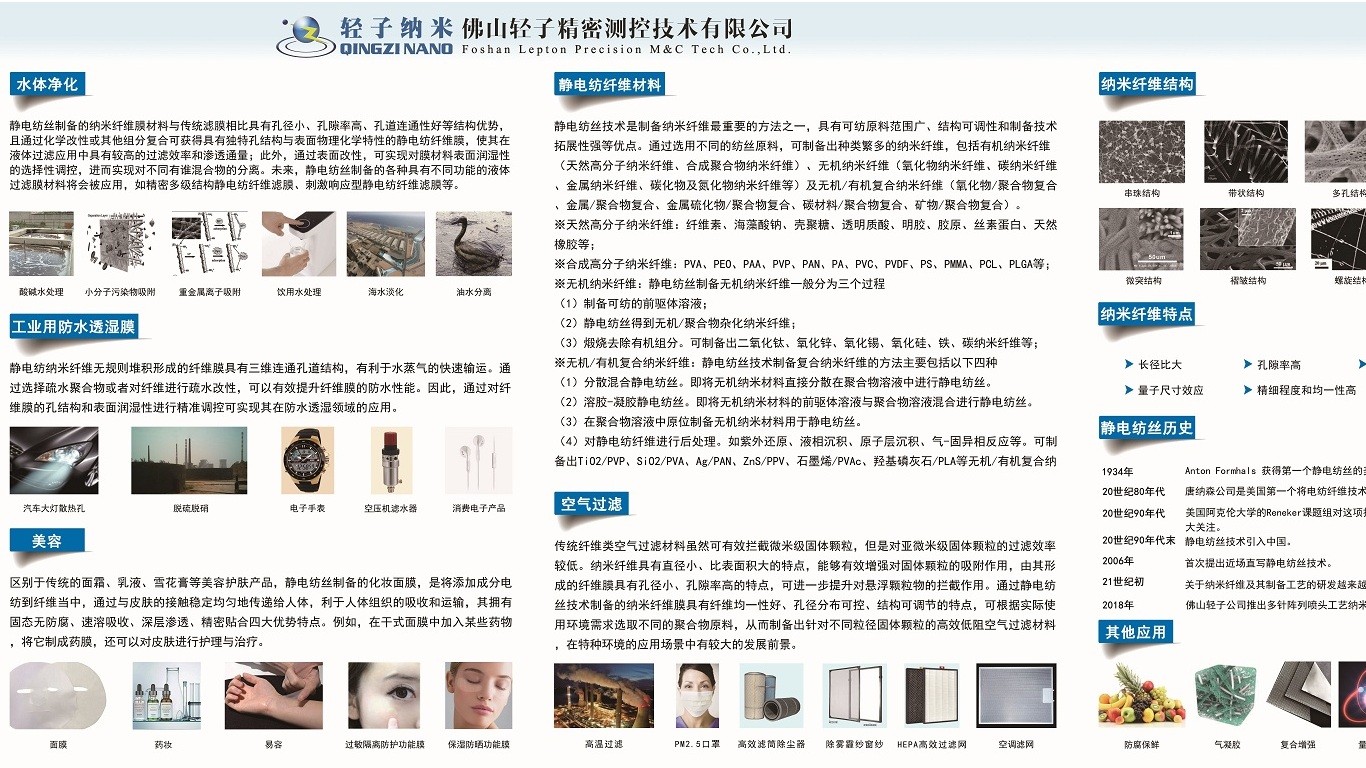

1. Water Purification

Preparation of electrospinning nanofiber membrane materials compared with the traditional filter membrane, with a small aperture, high porosity, pore connectivity good advantages, such as structure and composite can be obtained by chemical modification or other components with unique pore structure and surface physical and chemical characteristics of electrospinning fiber membrane, liquid filtration applications make it do have high filtration efficiency and permeation flux. In addition, through surface modification, the wettability of membrane material can be selectively regulated, and the separation of different oil-water mixtures can be realized. In the future, various kinds of liquid filtration membrane materials with different functions prepared by electrospinning will be applied to electrospinning fiber filtration membrane of precise multistage structure and stimulation-responsive electrospinning fiber filtration membrane.

(1) Acid Base Water Treatment

(2) Adsorption Of Small Pollutants

(3) Heavy Metal Ion Adsorption

(4) Potable Water Treatment

(5) Desalination

(6) Oil/Water Separation

2. Industrial Waterproof And Moisture Permeable Film

The fiber membrane formed by the random stacking of electrospinning nanofibers has a three-dimensional connected pore structure, which is conducive to the rapid transportation of water vapor.By selecting hydrophobic polymer or hydrophobic modification of fiber, the waterproof performance of fiber membrane can be effectively improved.Therefore, the application of the fiber membrane in the field of water and moisture permeability can be realized through the precise regulation of the pore structure and surface wettability of the fiber membrane.

(1) Radiator Vent For Car Headlights

(2) Desulfurization Denitration

(3) Electronic Watches

(4) Air Compressor Water Filter

(5) Consumer Electronics

3. Beauty

Electrospinning preparation of makeup mask is different from the traditional creams, lotions, cold cream, such as beauty products, it is to add components to electrospinning fibers, through contact with the skin, stable evenly is passed to the human body, beneficial to human tissue absorption and transportation, it has a solid no preservative, instant absorption, deep penetration, precision laminating four big advantage.For example, some medicines are added into a dry mask, which can be made into a medicine film, and can also be used for skin care and treatment.

(1) Mask

(2) Medicine Makeup

(3) Disguise

(4) Allergy Isolation Protective Functional Membrane

(5) Moisturizing Sunscreen Functional Film

4. Air Filtration

Although the traditional fiber air filtration materials can effectively intercept the micron solid particles, the filtration efficiency of the submicron solid particles is low.Nanofibers have the characteristics of small diameter and large specific surface area, which can further enhance the interception of suspended particles.By electrospinning technology system of the preparation of nanometer fiber membrane with good fiber uniformity, controllable pore size distribution, the characteristics of the structure can be adjusted, according to the actual use of the environment demand to choose different polymer materials, which could be prepared for different particle size of solid particles of high efficiency low resistance air filtration material, do the special environment of application scenarios have larger development prospects.

(1) High Temperature Filtration

(2) PM2.5 Masks

(3) High Efficiency Cartridge Filter

(4) Haze Screening

(5) HEPA Filter

(6) Air Conditioning Filter

5. Other Applications

(1) Preservative And Fresh-keeping

(2) Aerogel

(3) Composite Reinforced

(4) Quantum Light

(5) Insulated Window Screens

(6) Nanoparticles Disperse Carrier

6. Electrospinning Fibrous Material

Electrospinning is one of the most important methods to prepare nanofibers. It has the advantages of wide range of spinnable materials, adjustable structure and extensive preparation technology.By choosing different spinning raw material, with a wide variety of nanofibers can be prepared, including organic nanofibers (natural polymer fibers, synthetic polymer nanofibers) and inorganic nanofibers (oxide nanofibers, carbon nanofibers, metal fiber, carbide and nitride nanofibers, etc.) and inorganic/organic composite nanofibers (oxide/polymer composite, metal/polymer composite and metal sulfide/polymer composite and carbon materials/polymer composite).

(1) Natural polymer nanofibers: cellulose, sodium alginate, chitosan, hyaluronic acid, gelatin, collagen, silk fibroin, natural rubber, etc.

(2) PVA、PEO、PAA、PVP、PAN、PA、PVC、PVDF、PS、PMMA、PCL、PLGA等;

(3) Synthetic polymer nanofibers: PVA, PEO, PAA, PVP, PAN, PA, PVC, PVDF, PS, PMMA, PCL, PLGA, etc.

Inorganic nanofibers: the preparation of inorganic nanofibers by electrospinning is generally divided into three processes:

1) Prepare spinnable precursor solution;

2) Inorganic/polymer hybrid nanofibers were obtained by electrospinning.

3) Remove organic components by calcining.Titanium dioxide, zinc oxide, tin oxide, silicon oxide, iron and carbon nanofibers can be prepared.

Inorganic/organic composite nanofibers: the preparation methods of composite nanofibers by electrospinning technology mainly include the following four methods:

A. Dispersed mixed electrospinning.The inorganic nanomaterials were directly dispersed into polymer solution and mixed to conduct electrospinning.

B. Sol-gel electrospinning.The precursor solution of inorganic nanomaterials is mixed with polymer solution for electrospinning.

C. Preparation of inorganic nanomaterials in the original position of polymer solution for electrospinning.

D. Post-treatment of electrospinning fiber.Such as ultraviolet reduction, liquid phase deposition, atomic layer deposition, gas-solid heterogeneous reaction, etc.TiO2/PVP, SiO2/PVA, Ag/PAN, Zns/PPV, graphene /PVAc, hydroxyapatite /PLA and other inorganic/organic composite nanofibers can be prepared.