A motor is a device that converts electrical energy into kinetic energy. It has many types, and the phenomenon and cause of damage to different types of motors may vary.

First, the bearing is broken, the bearing temperature is too high, and the raceway and rolling elements are cracked and scarred.

1. Insufficient lubricating oil, aging or more, the lubricating oil should not exceed 70% of the bearing cap and bearing volume.

2. There is iron powder and other impurities inside the lubricating oil, or the oil ring inside is stuck.

3, not installed in place, such as bearings, bearing caps are not assembled, or too tight between the two. Concentricity is not right, there is eccentricity causing damage.

4. The coupling level is not adjusted well. The chain or belt between the transmissions is too tight, and the shaft is subjected to load force impact deformation.

5, the bearing quality is not good, the bearing clearance is too small or too large.

6, the motor start and stop frequency is too high, and the rigidity is too large, for some occasions should not be full pressure start, soft start will be better.

Second, the selection and installation problems

1. The level between the motor and the load is not adjusted well, causing a radial impact between the load and the motor.

2. The screws on the motor foot are not fixed, or the fixed shelf is not designed.

3, did not consider the load situation to select the type, some loads are frequently started and stopped, maybe only 1KW of power is calculated, the design considers the heat dissipation and the weakening problem, may need 3KW to use.

4, the line is wrong, for example, the star type is connected to the triangle type, and the triangle type is connected to the star type, which may cause the internal motor to overheat.

5. The load requires some special braking. The motor does not have a corresponding mechanical or electronic brake. It may not be able to release energy when parking.

6, the motor does not design some protection devices, such as overheating, overload, over temperature, lack of equal, these may occur during use, but because the protection is not in place, the motor will burn directly.

7. The wiring is wrong, or the reverse is reversed, or the wire is thinned, or the terminal wire is not pressed, resulting in excessive contact resistance.

8. If you use a photoelectric encoder or the like, you need to consider some dust protection and anti-collision protection.

9. If the drive is broken, it will cause high voltage or high current burnout on the motor side.

10, when the power supply, did not take into account the motor withstand voltage problems, such as 220 volts, using 380 volts into it.

11, some stepper motor and servo motor, can not be disassembled to replace the bearing or the like, otherwise it may lose magnetism or cause the encoder pole zero offset can not be used normally.

Third, environmental issues

1. In some occasions, there are many dusts. If a brushed DC motor is used, there is no intention to install a fan or the like to clear the dust in time, which causes the carbon brush and the commutator to wear out in a short time.

2, high temperature occasions, such as long-term than 50 degrees, and the load is relatively heavy, when selecting the motor, there is no high-temperature motor such as F and H, and no separate air-cooling system is designed, the long-term running motor temperature is too high.

3, the ambient humidity is too high, do not consider the details of the use of electrical insulation, may cause leakage on the circuit.

4. For shocks with large loads, consider the resonance problem. When fixing the motor, the direction of the screw should be considered whether it will loosen due to the difference in vibration direction.

Fourth, the motor quality problem

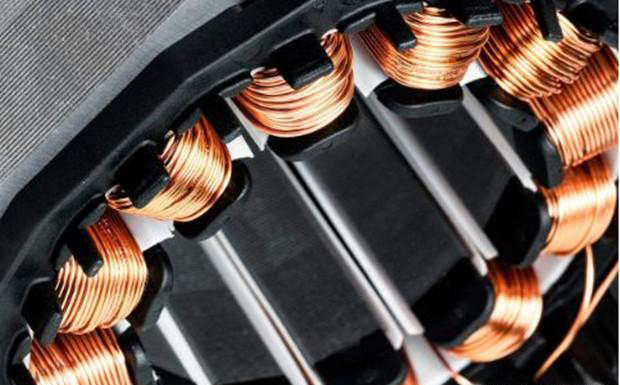

1. The copper wire of the coil winding is unqualified, or the number of turns is not enough, or there is a problem that the resistance values of the phases are different.

2. The squirrel cage guide bar rotor material is not closed, and it breaks during use.

3, the motor insulation is not good, the factory power supply sometimes the grid voltage will be high, the voltage slightly fluctuates, causing insulation breakdown.

4, some permanent magnet motors, magnetic materials are not resistant to high temperatures, loss of magnetism after a period of use.

In any case, in the process of using the motor, as long as the vibration is loud, the noise is loud, or there is an unusual taste, it is necessary to stop the machine and check carefully to ensure that there is no problem before continuing to use.