The degradation mechanism of the connector is very important to the performance of the connector, and it is very important to guarantee the performance of related products. What is the degradation mechanism? What factors cause the connector to fail? We will continue to explore this issue.

Connectors are used for connections between two separate systems. There are many reasons for separability, from the convenience of manufacturing to the improvement of performance. However, when matched, the connector should not increase any unnecessary resistance values between the systems. Increasing the resistance value may cause signal distortion or power loss and cause system failure. Connector degradation mechanisms are important because they are a potential source of increased resistance and, as a result, function failure over time.

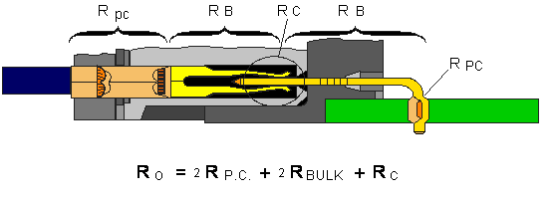

Let's first briefly review the resistance of the connector. Figure 1 shows a cross section of a universal signal connector. The equation in Figure 1 represents the various sources of resistance in the connector. Ro is the overall resistance of the connector, which is the resistance between the end of the conductor tail and the soldering point of the PCB connector pin. The two permanent connection resistors Rp.c refer to the resistance between the crimp connection point and the corresponding pin. Similarly, two body resistances (Rbulk) refer to the body resistance of the rear contact body and the parallel body resistance between the two posts of the connector; there is also a contact resistance Rc at the interface or separation. The overall connector resistance is the sum of the individual constant connection resistance, the back contact and cavity connection body resistance, and the detachable contact resistance, because all these resistances are connected in series.

Figure 1. Schematic of connector resistance.

For the sake of discussion, let us assume that the total measured resistance value Ro is 15 milliohms. With this assumption in mind, we speculate the relative effects of permanent connection resistance, bulk resistance, and detachable contact resistance on the overall connector resistance.

In this example, these values are the resistance values of a typical soft shell connector. The bulk resistance will account for most of the total resistance, which is close to 14 milliohms. The permanent connection resistance is several hundred micro-ohms, and the other is the contact resistance where it can be separated.

Although the bulk resistance of a connector contact is the largest contributor to connector resistance, it is also the most stable. The volume resistance of a single contact is determined by the material from which the contact is made and its overall geometry. In this simple example, considering the length of the conductor, the resistance can be calculated by the company: Rcond. = R ll / a.

In this equation, r is the resistivity of the conductor (also the spring material in the connector), "l" is the length of the conductor, and "a" is the cross-sectional area of the conductor (or the geometry of the spring in the connector) . For a given material, such as phosphor bronze and contact geometry, these parameters are constant, so the overall resistance of the connector is constant.

The permanent connection resistance and the interface or detachable connection resistance are variable. These resistors are susceptible to various degradation mechanisms, which will be discussed in later articles. It should be pointed out that the connector is affected a lot, such as harsh environment, heat, life, vibration and so on. And the total connector resistance may change from the original 15 milliohms to 100 milliohms, for example. The change in resistance mainly occurs in the detachable and permanent connection resistance. Detachable interfacial resistance is the most susceptible to degradation due to forces, deformations, and the like, where they can be separated.

Simply put, the two main separable interfaces require a certain amount of force and deformation. The bite force of the connector is the first and most obvious requirement. For high PIN number connectors, the bite force of a single PIN bit must be controlled, and contact normal force is one of the main parameters constrained by this requirement. For example, a detachable connection has a contact force of tens to hundreds of grams, while an insulation crimp connection, or IDC, has a force on the order of several kilograms, as does the corresponding force in a press-in connection. The high forces in this permanent connection provide greater mechanical stability and lower resistance values, much lower than the resistance values of detachable connections.

In the same situation, a higher permanent connection force allows greater deformation of the contact surface than a detachable connection. Crimp connections are the most obvious examples, such as significant deformation of a crimp terminal, and obvious deformation of a single conductor. Both the force of the crimp connection and the corresponding PIN foot allow greater deformation to contact the surface. As with higher forces, larger surface deformations of permanent connections reduce their resistance compared to detachable contact resistance.

Deformation of the separable interface is also limited by another separable interface requirement: mating durability. High surface deformations often lead to high surface wear, which in turn can lead to loss of contact coatings, such as gold or tin on the contact surface. The loss of this coating will increase the corrosion sensitivity of the contact surface, which will be discussed in a future article.

Compared with the permanent connection, the combination of the bite force and the bite durability of the separable interface limits the deformation and mechanical stability of the separable interface, which is also the reason for the lower electrical stability of the separable interface.

In general, the larger the contact area between two surfaces, the lower the interface resistance. In fact, for the resistance of the conductor length, the contact area between the two surfaces is similar to the equation Rcond. = R l / a. Detachable connections have higher resistance because they have a lower contact area than permanent connections.

In short, compared with the permanent connection, the reduced force of the detachable connection leads to a decrease in mechanical stability and a reduction in the contact area leads to a higher resistance.

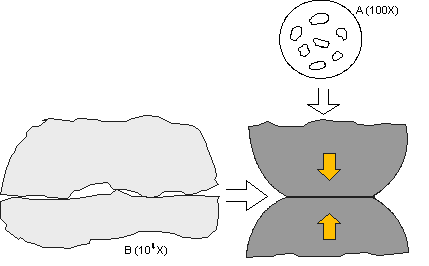

These problems, namely the reduction of contact force and the reduction of contact area, directly affect the degradation sensitivity of the separable contact interface. Figure 2 shows an enlarged schematic view of the detachable contact interface. The figure shows that at the microscale of this contact interface, all surfaces are rough. This means that the contact interface itself will consist of a distribution called point a or bumpy contact points, rather than a complete area of contact. This uneven structure is responsible for the increase in contact interface resistance. The reduced contact area, including the distribution of point a over a certain geometric area, depends on the geometry of the contact surface. A type of resistance, called a shrunk resistor, is created by the current being squeezed to flow through a single a point. Increasing the contact area by various methods can reduce the shrinkage resistance, but it cannot be eliminated. Therefore, connectors always add some resistance to the electrical system. From this perspective, the primary goal of connector design is to control the size and stability of the resistor.

Figure 2: Microscopically looking at the inherent surface roughness of the contact interface.

As mentioned earlier, the size of the interface resistance depends on the area of contact that occurs when the plug and socket contacts come into contact with each other. There are two main factors affecting the stability of contact resistance: disturbance at the contact interface and corrosion at point a. How these factors affect the connector degradation mechanism will be discussed later. In summary, these mechanisms include:

1. Corrosion occurs at and around the contact interface, thereby reducing the contact area. There are two types of corrosion mechanisms: surface corrosion, which directly affects the contact area; induction or fretting, which can increase the contact interface's sensitivity to corrosion.

2. Loss of the integrity of contact plating due to insufficient plating or abrasion, which increases the sensitivity to corrosion. Most connector contacts are surface layers that are plated with a precious metal, such as gold; or ordinary plated surfaces, which are usually tin. One of the main purposes of these coatings is to protect the contact substrate (usually a copper alloy) from corrosion. The corrosion sensitivities of precious and non-precious metals are different and will be discussed separately later.

3. The contact force is lost, which causes the mechanical stability to decrease, and the contact interface is susceptible to fretting. The main mechanism that causes the contact force of the connector to decrease is excessive contact stress and stress relaxation. Due to the effect of time / temperature, stress relaxation refers to the loss of contact force with time.