With OP Module,away from long business trip trouble!

For the automation equipment manufacturers, engineers is always the important part,they starts working when customer plan to order the machine. First, he needs to discuss the specific production process requirements of the machine with the mechanical engineer repeatedly; draw the circuit diagram to the electrician wiring, and then confirm the order list to purchasing Department, then programming until the machine parts and circuits are installed. When it is shipped, help the electrician to check the wiring errors, the sensor installation, the parameters of the servo, inverter, thermostat and other components. After doing this, it is the real beginning of the debugger. In order to meet the strict requirements of the customer's process, the general electrical engineer will go to the site after the machine is shipped. The electrical engineer has been debugging the equipment in the first line, often for one month, and cannot go home until the machine can stabilize production. Not only increases the cost, but also reduces the efficiency of debugging detection.

However, equipment sales are only the first step, and then there will be remote maintenance of the equipment. Equipment is sold to different region and around the world, program debugging is a big problem. We have a customer Mr Wei said that their company's sales performance was very good last year, and exported a lot of equipment to India, Turkey, Southeast Asian countries, and he also traveled to India for almost a month for business. the customer feedback product there are still some problems after using it for a while, and the PLC needs to do some upgrades. However, the customer does not understand the PLC program, and even remote control the customer can’t sure what to do. The customer asked to let the technician go to the site to help for extra half month which add both side’s cost and delay the production efficiency considering of visa, schedule etc. If there is an offline programming module that can communicate with the PLC, it is perfect to directly upload and download the program.

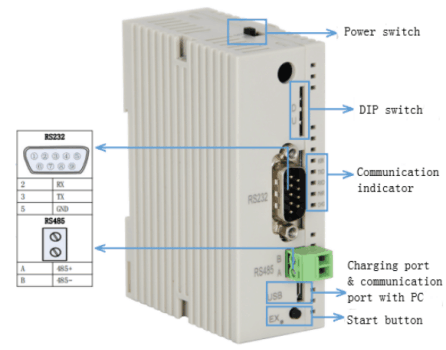

For this, Coolmay has developed a CM-OP offline programming module, as a wired data transmission module, using RS485 and RS232 communication methods, so that the module communicate to PLC, directly uploading and downloading the program. Especially for the automation equipment on the production line, making the program download work so easy and convenient. Keeping engineers away from production line noise and improving the working environment greatly, meantime improving work efficiency.

Coolmay CM-OP offline module advantage

The operation is simple and easy to learn, and the production line workers can easily master how to use it.

1. Reduce equipment downtime. When programming the next task, the previous equipment program can still work on the production line;

2. For the automation equipment on the production line, using the module to download the program from the PLC can make the programmer away from the heavy handling work and improve the programming environment;

3, Offline programming is widely used, not only can read and write programs such as Coolmay 2N series, 3G series and other PLCs, but also can work with original Mitsubishi 2N and 3G series PLCs;

4, Can easily achieve optimal programming;

5. It is convenient to change the PLC program and improve work efficiency;

6, No parameter setting,only plug it and play, convenient to use and high adaptability;

7, Built-in rechargeable battery, can be used continuously for more than 5 hours after charge;

Offline module usage

Write a program from the module to the PLC

1. Power on the PLC. The RUN/STOP switch is on the STOP state.

2. The module D/U (download/upload) switch should to be made on the D (download) state.

3. The module and PLC are connected by RS232 or RS485.

4. Power on the module, that is, the power switch is turned ON.

5. After about 2S,when the WORK light flashes,it indicates that the communication with the PLC is successful.

6. Press the EX. button ( start work ).

7. At this time, the module RXD light flashes, the TXD light flashes quickly, and the WORK light flashes normally.

8. Wait until the RXD light stops flashing, that is, after the RXD and TXD lights are off, the program download is completed.

Reading a program from a PLC to the module

1. Power on the PLC.

2. The module D/U (download/upload) switch should to be made on the U (upload) state.

3. The module and PLC are connected by RS232 or RS485.

4. Power on the module, that is, the power switch is turned ON.

5. After about 2S,When the WORK light flashes, it indicates that the communication with the PLC is successful.

6. Press the EX. button (start work button).

7. At this time, the module TXD light flashes, the RXD light flashes quickly, and the WORK light flashes normally.

8. Wait for the TXD light to stop flashing, that is, after the RXD and TXD lights are off, the program upload is completed.

Introduction of DIP switch when writing and reading

PLC write | PLC read | |

PLC Statue | STOP | Support STOP,RUN |

Module D/U Statue | D | U |

With offline programming module, direct do remote debugging, debugging PLC program well. Send the CM-OP offline programming module to the customer. It doesn't matter whether the customer understand the PLC program or not. Write the program to the PLC in a few simple steps, away from business trips.