Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

Product Details

Details | ||

Item Number | CYNL005 | |

Product Size | 62*62*26 mm/ 2.4*2.4*1.2 inch | |

Product Weight | 60g / 2.1oz | |

Material | ABS | |

LED Type | RGB | |

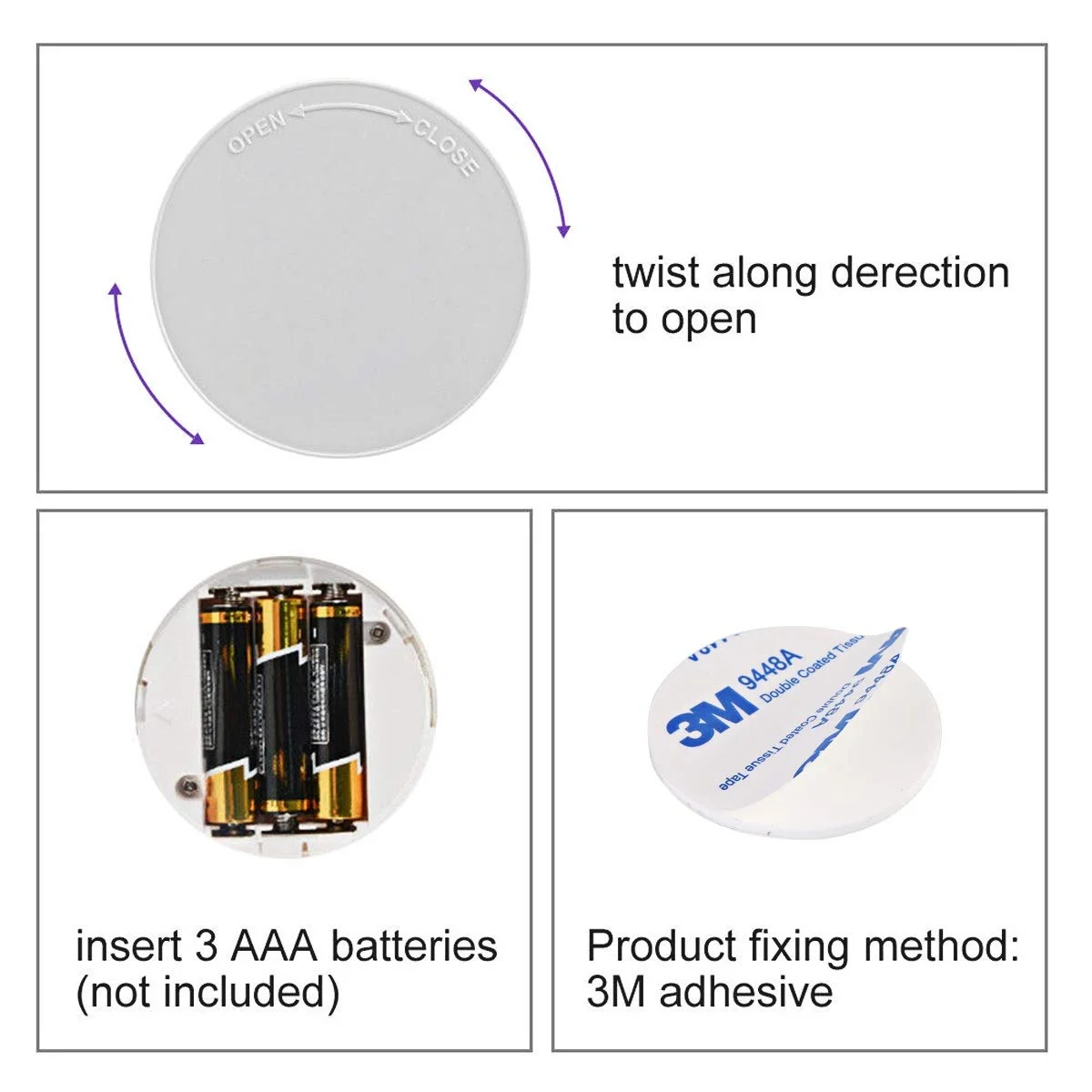

Battery Type | 3*AAA | |

Max.Lumen | 60 lm | |

Lighting Time | 100 h | |

* Item Type : LED RGB Dimmable cabinet light

* Emitting Color: RGB (13 Color to choose , can be controller by remote)

* Brightness: Adjustable

* Control Method:Touching or Remote controller

* Application:Ideal for Kitchen,Closet, Cabinet, Bookcase, Bedroom, Jewelry Display Case, Basement etc.

* Size: 62*62*26mm

* Lamp battery : 3X AAA batteries (Not include)

* The Remote Controller: CR2025 button battery (Not included)

* Control distance: 8 meters

Note:

* When the battery is installed or replaced, the bottom cover must be turned counter clockwise to open,

* Do not soak in water, do not disassemble anyhow.

* Please remove the transparent insulating sheet from the remote control when using it for the first time.

Better Injection System

The enhanced double-cylinder dual-extruding ejection structure will produce a lower back pressure in the oil return during ejection, and have a quicker injection speed and longer service life.

Electronic Control System

By using the all-digital communication technology, it will show a clear improvement in all technical indexes, and acts more accurately in the pressure and flow rate control.

Lower Costs

The collective result of high speed, efficiency, specialization, precision and most of all, fewer labor hours, all add up to a better bottom line for your business. Saving money or making more money is one of the popular benefits of CNC machining.

Mechanical Vertical-Compression Structure applied by Our Injection Molding Machine

• 100% clamping use ratio, 10%-20% higher than that of traditional structures;• Less fins on the finished products;

• 2%-6% raw materials saved from production than that of traditional structures;

• Effective protection for the mould, molding board, and pull rod;

• Lead to loss of clamping force, only 70%-85% left;

• Displacement of the molding board may cause deformation and fins, and a waste of the labor force and raw materials.

We only use Aircraft Grade Aluminum

Our products are made of high quality aluminum alloy, they are sturdy and durable enough for long time daily using.

Share

Share

Customer Reviews total 0 items