North America 50.00%

Western Europe 20.00%

Eastern Europe 10.00%

Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

TMAX-1200Cfurnace split tube furnaces feature the famous spiral wire coils embedded in Mitsubishi (Japan) high quality grade 1500 alumina fiber insulation. A double walled steel internal housing helps minimize heat loss to exterior surface.

Furnace operation is controlled by Shimaden (Japan) 40-segment digital controller with built-in RS485 digital communications port and USB adaptor, allowing the user to connect to a PC for remote control and monitoring of the furnace. You can also save or export test results.

CE Certified 1200C High Temperature Vacuum Tube Furnace (Dia 60-250mm) Support Customized size

Features

1 Compact, portable and lightweight design.

2 Split furnace chamber for fast and easy tube access.

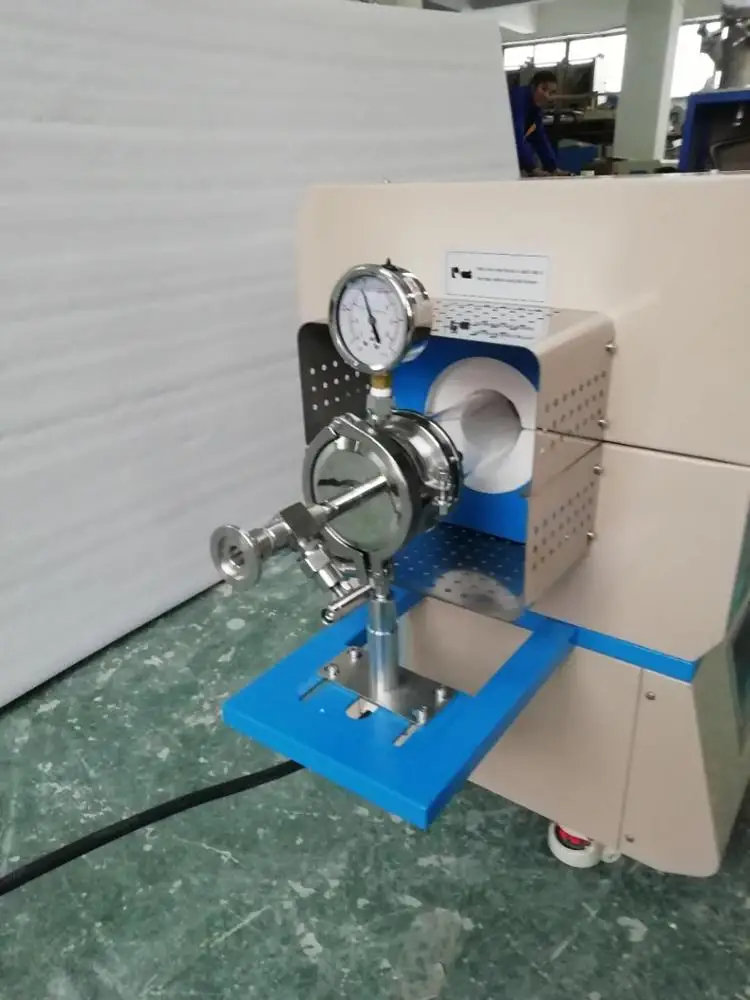

3 Standard package includes set of stainless steel vacuum sealing flanges with valves and pressure meter.

4 Microprocessor based self-tuning PID control provides optimum thermal process with minimal overshoot.

5 Multiple atmosphere processes in a single cycle are possible (ex: binder burn out in air and parts sintering under rough vacuum or inert gas environment.)

6 Built-in ammeter and dual voltmeters for easy monitoring and troubleshooting.

7 Built-in computer interface.

8 Long life type K thermocouple.

Safety

1 Overheat protection shuts down the furnace if temperature is outside of acceptable range (refer to controller's manual) or when the thermocouple is broken or malfunctions.

2 Power failure protection resumes furnace operation right after the point of failure when power is reestablished.

Warning! NEVER fill furnace with explosive gases, including Hydrogen, Carbon Monoxide and Methane.

General specifications

|

Electrical requirements |

110-240VAC, 50/60 Hz, single phase |

|

Tube material |

Quartz |

|

Maximum working temperature |

1200°C |

|

Maximum constant working temperature |

1100°C |

|

Constant working temperature under vacuum |

1000°C |

|

Minimum working temperature |

Ambient |

|

Rated vacuum pressure |

0.001 Pa / 0.0075 millitorr / 0.00001 mbar |

|

Rated positive pressure |

0.02 MPa / 150 torr / 3 psi |

|

Heating element type |

Kan-thal (Sweden) resistance coil wire |

|

Thermocouple type |

K |

|

Refractory lining |

Mitsubishi (Japan) high quality 1500 grade fiber alumina |

|

Temperature controller |

Shimaden (Japan) fp93 (made in Japan) with 4 programs and |

|

Maximum heating & cooling rate |

< 30°C / min |

|

Heating zone length |

16 inches |

|

Constant temperature zone length |

10 inches |

|

Temperature controller precision |

+/- 1°C |

|

Vacuum sealing flange kit |

Stainless steel vacuum sealing flanges with one vacuum gauge, |

|

Gas inlet/outlet |

1/4" hose barb with 1/4" BSPT (British Standard Pipe Thread) |

|

CE compliance |

Yes |

Size comparison

|

Tube size (OD x length) |

60mm x 1m |

80mm x 1m |

100mm x 1m |

120mm x 1m |

150mm x 1m |

200mm x 1m |

250mm x 1m |

|

Maximum output |

2.5 kW |

3.5 kW |

3.5 kW |

4 kW |

5 kW |

6 kW |

8 kW |

|

Furnace dimensions (LxWxH) |

24x15x20" |

24x17x23" |

24x17x23" |

24x17x23" |

24x18x24" |

26x21x28" |

26x21x28" |

|

Shipping dimensions (LxWxH) |

46x21x36" |

46x21x36" |

46x21x36" |

46x21x36" |

46x22x37" |

50x28x40" |

50x28x40" |

|

Shipping weight (Lb) |

260 |

300 |

340 |

400 |

450 |

500 |

650 |

|

|

||

|

About Product

Q1:Which procedure to secure your Quality? A1:Our company has own research & development and production base, the products have been calibrate by central laboratory professionals before before they leaves the factory, ensure the accuracy of test results and authority.

Q2:How about your company product after-sales service system? A2:Product after-sale guarantee period is 12 months,and we can provide lifetime repair guarantee.We have agents in some countries,they can provide door-to-door service.If there is no agent,our professional pre-sales and after-sales department can reply you within 24 hours for any technical problems.

Q3:Products standards? A3:Our instruments adopts ISO, ASTM, DIN, EN, GB, BS, JIS, ANSI, UL, TAPPI, AATCC, IEC, VDE and other international testing standards.

Q4:Our country's power supply and plug are different, how do you solve it? A4:We can according to different countries and the power plug, equipped with transformer and plug that in accordance with your local requirement.

Q5:Payment methods? A5:T/T, L/C, D/P and so on.

Q6:Packing method? A6:Standard export wooden box packaging.

Q7:How about customers evaluation for your products? A7:Our company has established long-term cooperation with the SGS, Bureau Veritas, TUV and Intertek,our high quality products and first-class after-sales service.Our services get the trust of the customer satisfaction and recognition for themselves.

Q8:Main export market? A8:Now our products have been exported to North America, Europe, southeast Asia, South America and other countries.

Q9:How to ensure the customer standard use the instrument? A9:We can provide each product related video showing how to install and operate.If you have specific needs, we also can arrange engineer to the customer's company for equipment operation training.

About Shipping Q1:Order processing? A1:Please allow a processing time of 12-24 hours for your order(s) to ship. Equipment orders will take up to 2 weeks before leaving our warehouse. (Order processing is done during normal weekdays only, no holidays or wee.

|

||

Customer Reviews total 0 items