Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

Product Details

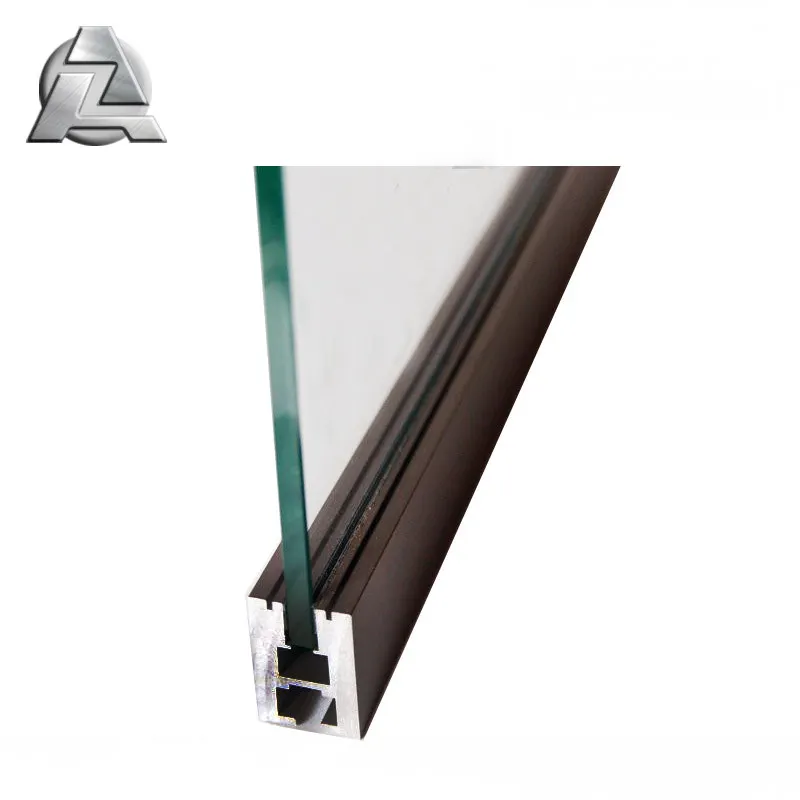

50mm waterproof anodized aluminium profile led strip rails light

| Aluminum Alloy | 6063, 6005, 6005A, 6105, 6101, 6082, 6061 |

| Tempers | T4 , T5 , T6 |

| Extrusion Capacity

2750 Ton, 10" Press |

Surface Treatment

Mill finish , Sand Blasting , Anodizing , Wood grain , Electrophoresis painting , Powder coating * Powder coating thickness: 60-120um * Anodizing thickness: 8-25um | |

| Fabrication

Cutting Countersinking Punching Notching Bending Deburring Drilling Tapping Milling Forming |

Design *Engineering -CAD Shape Design |  |

Standard Dies Shape | |

Angles(equal) , Angles(unequal) , C shapes , Caps , Carpet bar , Channels , Corners | |

Tolerance | |

According to GB5237.1-2008 or as per agreement

| |

Industry Standards | |

ISO9001: 2008 , ISO14001: 2004 , ISO10012 , AAA grade standardize corporate | |

| Testing | |

Validation , Durability , Reliability , Mechanical , Chemical , Physical , Dimensional , | |

A. Inside: packed with the plastic protective film or customized.

B. Outside: plastic shrink film for each bundle first,then waterproof kraft paper for each box.

C. Carton:20 pieces per bundle, 80-200 per carton.

SUPPLYING YOU WITH SOLUTIONS

Phone support: speak to a friendly voice you trust to get the job done

Industry leading practises: take the stress out of material control

On the case: we make sure every order is chased

In the know: one step ahead, recording the progress of your order

Comprehensive technology: we use the latest technology to stay ahead

Mail us any time: fast and reliable responses to inbound email

| Q1: What are the advantages of using the 6000 series of alloys in aluminum extrusions? |

A: The 6000 series, which incorporates magnesium and silicon, provide good extrudability, strength, corrosion resistance, formability and machinability -- which explains why it’s also ZJD’s alloy of choice for all our aluminum extrusions. |

| Q2: If I wish to send an electronic drawing to you, what types of files can you accept? |

A: We accept many file formats such as DXF, DWG and IGES. |

Q3: Why do extrusion companies always ask me to sign off on a drawing before they can order tooling if I’ve already provided a drawing? |

A: Oftentimes, we find a few key dimensions that are missing from the original drawing that need to be clearly identified. Other times, we have taken exception to a tolerance, dimension, alloy, note, surface condition, etc. It’s just our way of documenting exactly what we have agreed upon. |

| Q4: What is the difference between anodized and mill finished? |

A: Mill is the raw state of aluminum as extruded - no surface treatment. Anodized (also known as Satin Clear or Clear Anodized) is an electrolytic process. This process increases corrosion resistance and weather resistance. |

| Q5: What About Anodizer Rack Marks? |

A: Electrical contact must be made to each part to be anodized. The more electrical current required, the greater the electrical contact. The size of the contact therefore depends on the anodizing process and the size of the part being anodized. |

Q6: What is your closest sea-port ? |

A: Dalian City SeaPort . |

Share

Share

Customer Reviews total 0 items