Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

Product Details

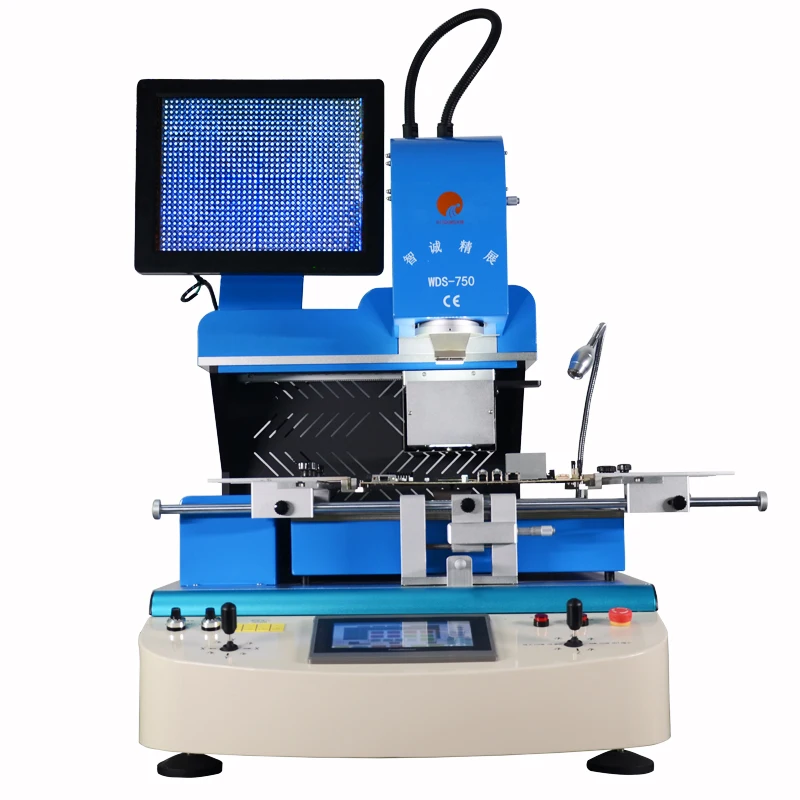

Auto feed and pick up chip soldering station WDS-750 entry level bga rework station replacement led lcd tv screens

Parameter of WDS-750

|

Power |

6800W |

|

Up heater power |

1200W |

|

Down heater power |

1200W |

|

IR heater power |

4200W(2400W control) |

|

Power supply |

(Single Phase) AC 220V±10 50Hz |

|

Position way |

Optical lens+ Vshape holder+laser positioning |

|

Temperature control |

High precision K shape sensor(Closed Loop),up and down independent temperature heating zone,Precision can reach±1℃ |

|

Material |

High sensitive touch screen+temperature control module+PLC+step drive |

|

PCB Size |

Max:550×480mm |

|

PCB Size |

Min: 10×10mm |

|

Thermo-couple Ports |

4pcs |

|

Chips magnification times |

2-30 |

|

PCB thickness |

0.5-8mm |

|

BGA size |

0.8mm-8cm |

|

Min.chips space |

0.15mm |

|

Max.Mount loading |

150G |

|

Mounting precision |

±0.01mm |

|

Size |

L830×W670×H850mm |

|

Optical alignment lens |

Motor drive can move front back right left |

|

Weight |

90kg |

Feature of WDS-750 ccd camera bga rework station :

»»» 1. Touch screen with human interface,heating time,heating temperature,reflow temperature rate,advanced alarming,vacuum time all can set inside the touch screen,simple operation,easy learn.

»»» 2.PLC import from Japan,temperature control module use China famous brand,display three temperature curves,4pcs independent temperature sensor,which can measure the different place temperature of the chips,make sure the rework rate. ccd camera bga rework station

»»» 3. Three independent heating temperature zone,each heating temperature zone can independently set the heating temperature ,heating time,rate;six heating temperature sections,Simulate the reflow oven heating mode

[preheating,constant,warming,soldering,reflow soldering,cooling]

»»» 4. Auto feed chips,pick up chips,blowing chips;auto recognition chips place during alignment Multifunction mode [weld,remove,mount,manual],realize semi auto and auto function ,meet customer’s requirement.

»»» 5.High precision K-type Closed Loop import from USA together with our company special heating way,the soldering rang of temperature within ±1℃

»»» 6. Imported optical alignment system with 15’’high definition monitor;high precision micrometer adjust X/Y/R axis;make sure the alignment precision within 0.01-0.02mm.

»»» 7. Top heater and mounting heater design2 in 1 which can make the mounting more precision;there are many sizes of BGA nozzles which can meet different chips sizes,BGA nozzles can easy change,we accept customize.

»»» 8. High automatic and precision,Completely avoid human operation error; it is good for reworking lead free craft and double BGA,QFN,QFP,capacitance-type resistor components which can achieve good result.

»»» 9. Additional monitoring camera which can observe the solder ball melting and easy to check the temperature curve and the soldering result(optional function) smartphone repair machine

Application of WDS-750

We also provide other Accessories :

Likes Solder ball (lead/lead-free) , BGA reballing kit , BGA flux, Heat tape, Solder Paste,

BGA reballing Stencils

Packing & Shipping of WDS-750 BGA Rework Station .

♦ Standard export wooden package for bga rework station.

♦ Delivery in 2 workdays after payment confirm .

♦ Shipping by TNT, UPS ,DHL,FEDEX (IE), Aramex or by air or by sea.

♦ Loading Port: Shenzhen or Hongkong.

RFQ :

1) This is the first time I use this kind of machine, is it easy to operate?

There is english manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea

Your inquiry will be replied in 24 hours

1.Offer free spare parts and service within one year of warranty,but all the other relative cost should be on the buyer's account;

2.Technology Support :Provide Demo operation video for training ;If you have time,welcometo our company,will arrange engineers to show you the operation;

3.Good and professional after-sales service;

4.Give great discount to AGENCY to ensure agents profit.

Welcome to visit our factory !

Share

Share

Customer Reviews total 0 items