Machine rollers

Roller Material:Roller material:Cr12.

Surface of Roller: Heat treatment HRC58-60.

Forming station: 12 stations.

Mid East 60.00%

Domestic Market 30.00%

South Asia 10.00%

Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

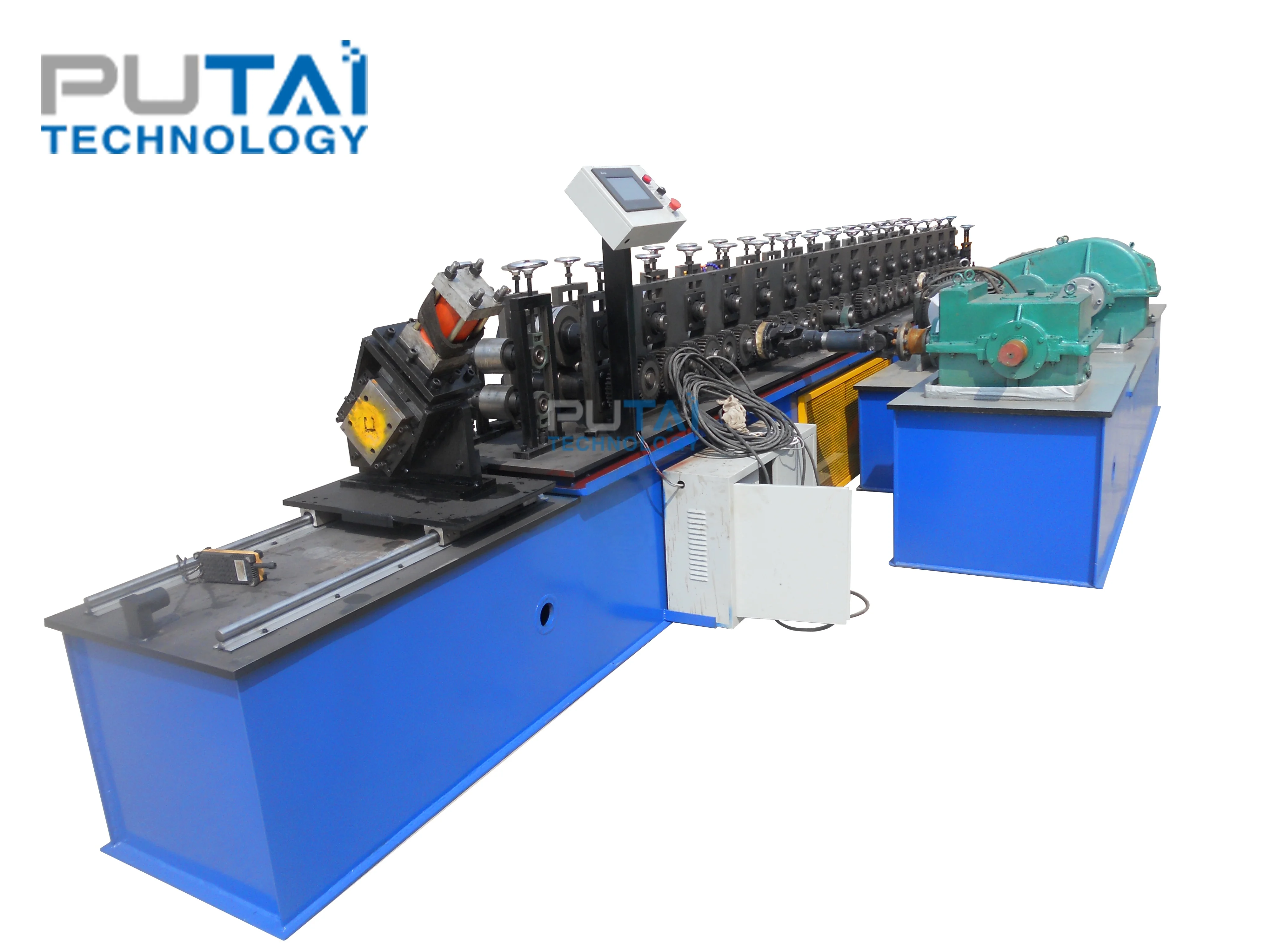

professional facotry light gauge steel omega channel cold roll forming machine's introduction

1.the main parts:

1) roll forming machine

2)molding press

3)cutting machine

4)PLC computer control

5)hydraulic system.

2. The machine is stable,no noise,no shake.

3. Controlling by computer, PLC display, operation is easy, running is steady and reliable,endurable

4. cutting machine is characterized by stable driving, easy operation.

5. hydraulic system use hydraulic pump, long operating life,no noise.

6. material: galvanized,colored steel or aluminum coil

7. We can make and design the kinds of roll forming machine according to customer's request.

Specifications for Ceiling Drywall Stud Partition Formar Machine Light Gauge Suspended Machine | ||||||

Manual Un-coiler | Max Capacity: 5000kgs | |||||

Inner diameter of coil:400-600mm | ||||||

Manual with brake | ||||||

Leveling Device | Ensure the material level and straight | |||||

The width can be adjusted | ||||||

Main Forming System | Width & Height & Thickness of sheet: According to Drawings | |||||

Material: GI sheet coil or Colored sheet coil | ||||||

Motor Power: 5.5 kw forming system | ||||||

Roller material:Cr12 | ||||||

Surface of Roller: Heat treatment HRC 58-60 | ||||||

Diameter of main shaft: 60mm #45 steel, heat treat modulation | ||||||

Forming station: 12 stations. | ||||||

Transmission: by chain and gear | ||||||

Measuring accuracy: +/- 0.5 mm/M. | ||||||

Arch middle plate: 30mm thickness. | ||||||

Output: 8-10 Tons per shift (8 hrs.). | ||||||

The machine base is assembled and welded by high quality steel. | ||||||

Cutting way: Tracking .. | ||||||

Oil pump station: 1set | ||||||

Motor power of Oil pump station: 7.5kw with cooling system | ||||||

Forced air cooling device available. | ||||||

Cutting mould: 1 sets | ||||||

Material of blade: CR12 with heat treatment HRC60-62. | ||||||

Electrical System | Control system: HMI & PLC control panel | |||||

Power: 380V 50Hz (as per local requirement) | ||||||

Run-out Table | Frame: A3 steel | |||||

Roller type | ||||||

Quantity: 1 pc | ||||||

1.Professional: rich experience in product and export process!

2.Low price:Save your money from every part!

a.Low labor cost

b.Convenient transportation;

c. Complete supporting industries

3.PLC: Ensuring high accuracy and easy to operate!

4.Full Automatic: Just input length of the sheets and numbers of the piece you need, then the machine automatically produce the product you need!

Machine rollers

Roller Material:Roller material:Cr12.

Surface of Roller: Heat treatment HRC58-60.

Forming station: 12 stations.

Name: hydraulic pump

Cutting way: Tracking.

Oil pump station: 1set

Motor power of Oil pump station: 7.5kw with cooling system.

Packaging | ||

Size | 3.1m(L) * 0.7m (W) * 0.9m(H) | |

Weight | about 2 T | |

Packaging Details | 1). Tighten to container with steel wire rope and welded machine with container by angel iron 2). Main forming machine and un-coiler is naked(If you need we can also packed with water-proof plastic) 3). PLC contral system and motor pump are packed in box with water proof paper coverage | |

Packaging | ||

Size | 123 (L) * 456 (W) * 789 (D) | |

Weight | 1.2 T | |

Packaging Details | ||

Customer Reviews total 0 items