North America 50.00%

Western Europe 20.00%

Eastern Europe 10.00%

Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

Features

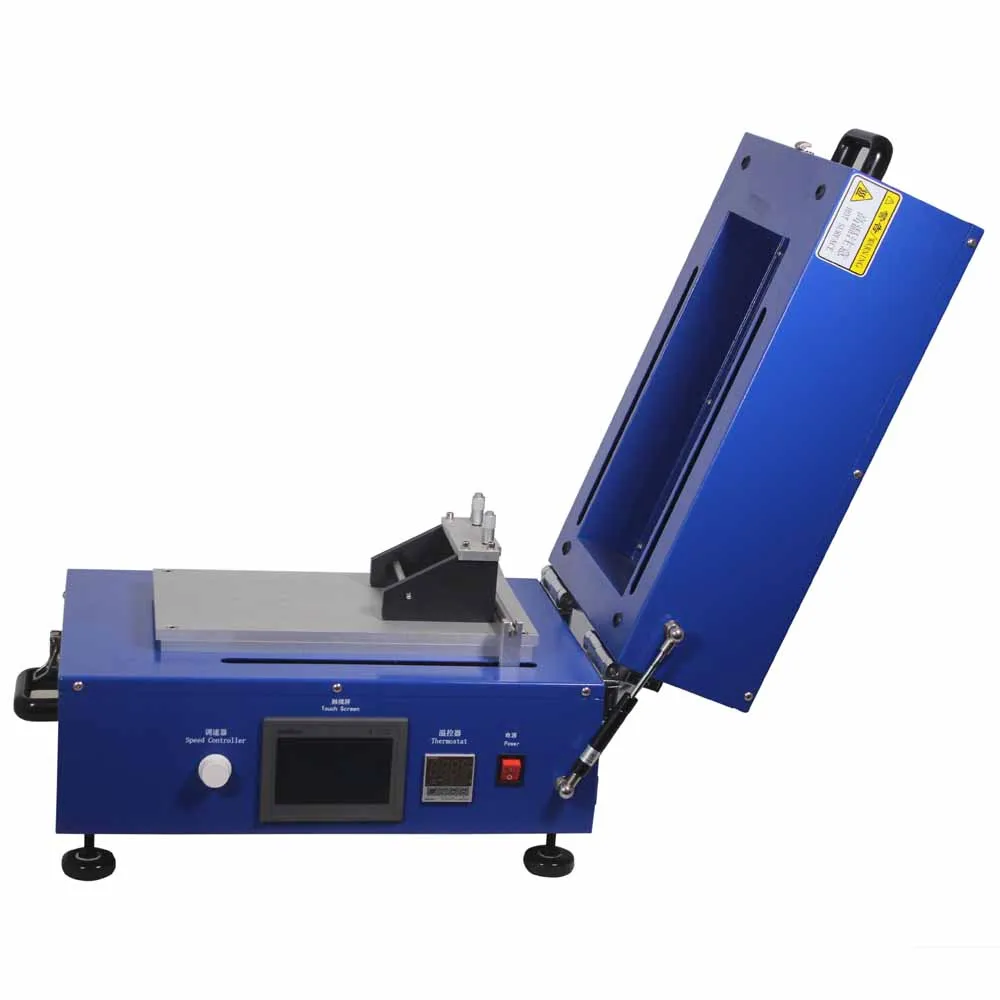

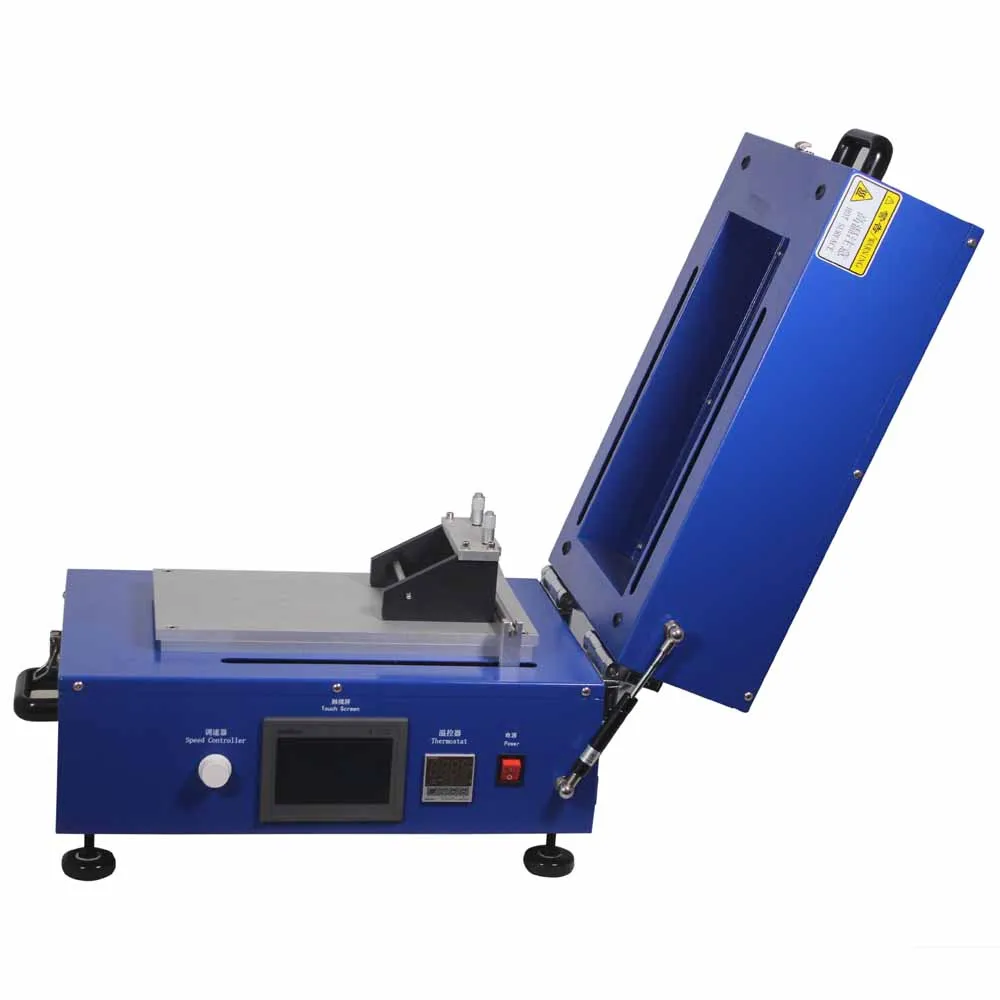

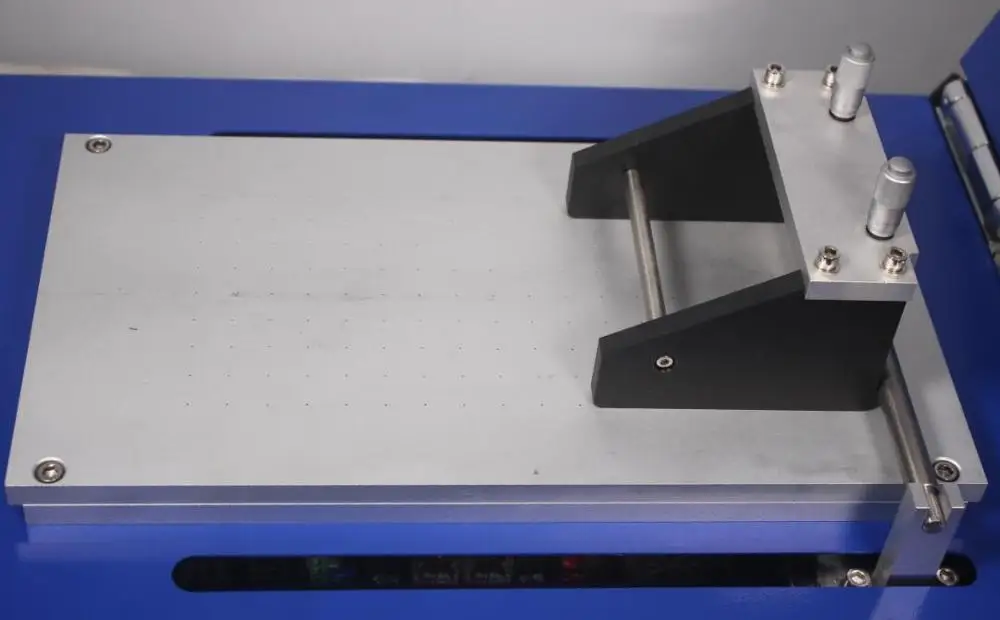

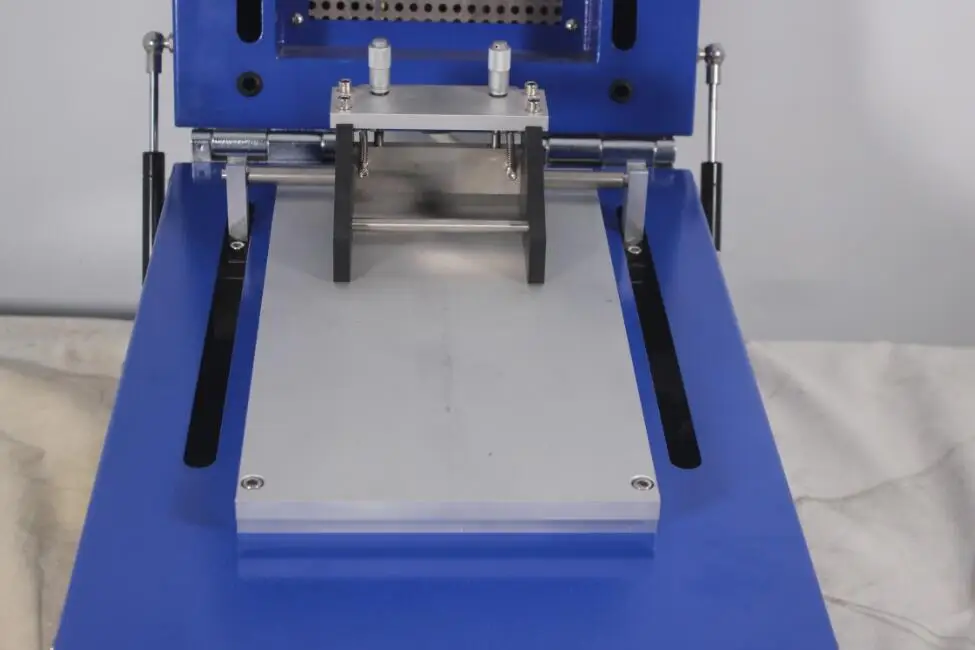

TMH800-250 is a CE Certified ready compact tape casting coater with a heating cover designed to produce films with consistent thickness. It has a unique driving system to produce a smooth coating on all types of materials. The flat vacuum chuck is built in to hold the substrate sheet in place, which is particularly useful when making thin coatings. There is a 100 mm width adjustable micrometer applicator (doctor-blade).

Heating cover with digital temperature controller can dry films after coating up to 100°C with a temperature accuracy of +/-1°C. This equipment can be used for researchers on ceramic tape castings and Li-Ion battery electrode coating.

Technical Parameter

|

Model |

TMH800-250 |

TMH250-100 |

TMH250-150 |

TMH250-200 |

TMH300-250 |

TMH350-250 |

TMH550-250 |

|

Stroke Length |

10 - 800 mm adjustable by using Adjustable Position Switch |

10 - 250 mm adjustable by using Adjustable Position Switch |

10 - 250 mm adjustable by using Adjustable Position Switch |

10 - 250 mm adjustable by using Adjustable Position Switch |

10 - 300 mm adjustable by using Adjustable Position Switch |

10 - 350 mm adjustable by using Adjustable Position Switch |

10 - 550 mm adjustable by using Adjustable Position Switch |

|

Platform |

Aluminum alloy flat vacuum chuck |

Aluminum alloy flat vacuum chuck |

Aluminum alloy flat vacuum chuck |

Aluminum alloy flat vacuum chuck |

Aluminum alloy flat vacuum chuck |

Aluminum alloy flat vacuum chuck |

Aluminum alloy flat vacuum chuck |

|

Accessories: Film Applicator |

Optional 50 upto 250 mm width micrometer adjustable film applicator is included, with adjustable thickness from 0.01 mm - 5 mm |

||||||

|

Optional Heating Cover Voltage and Power |

110VAC or 220VAC |

||||||

|

Traverse Speed |

0 - 20 mm/sec variable |

||||||

|

Vacuum Pump |

Vacuum pump is included |

||||||

|

Heating Cover |

1. Pre-installed on the top cover |

||||||

|

Compliance |

CE Certificate |

||||||

|

Warranty |

One Year limited warranty with lifetime support |

||||||

Pictures of Product

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.

Customer Reviews total 0 items