The high-quality materials can fabricate the high-quality products. Ditai Having a complete plastic sheet production line which helping to control the quality and cost better

Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

Product Details

Product Description

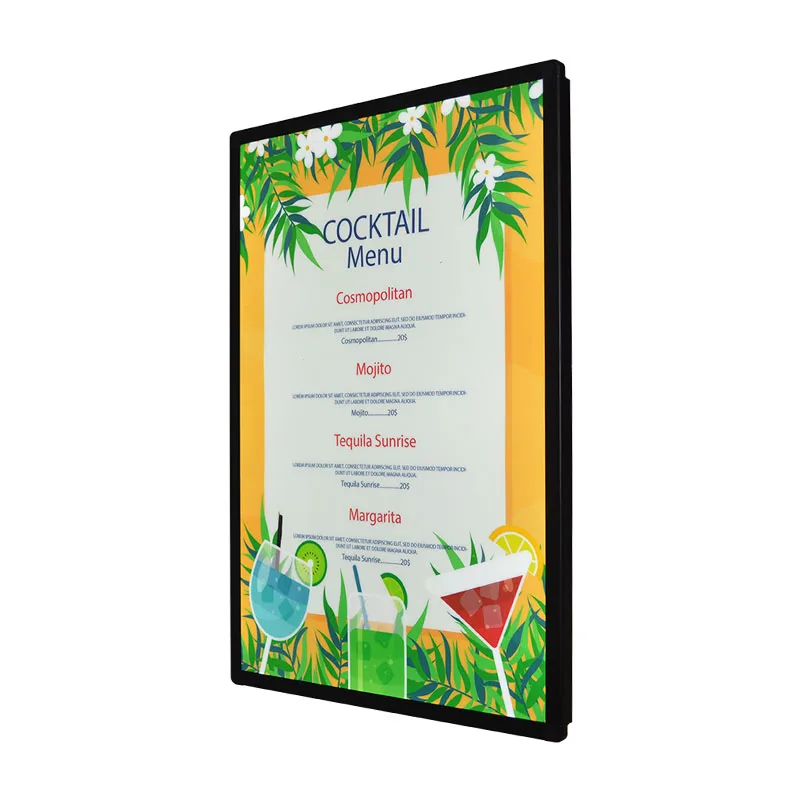

Custom 3d vacuum forming acrylic LED lighted up thermoforming Ice Cream Advertising Light Box Sign

type | Ice Cream Advertising Light Box Sign |

color | customized. |

logo | customized. |

MOQ | 100 |

Material Suggestion For Your Products:

When choosing a plastic, you'll need to consider application. Will your product be used inside our out? Will it be exposed to

extreme heat or cold? Does the product need to withstand high impact? Are you looking for something that's fire retardant?

As a general rule of thumb, we work to the following guidelines.

The following chart provides additional information about various plastic materials and their uses.

extreme heat or cold? Does the product need to withstand high impact? Are you looking for something that's fire retardant?

As a general rule of thumb, we work to the following guidelines.

The following chart provides additional information about various plastic materials and their uses.

plastic material | advantage | disadvantage | industry example |

ABS (Acrylonitrile Butadiene Styrene) | Engineered plastic that can be customized to desired levels of stiffness, hardness, heat deflection, and many other characteristics | UV sensitive – requires a UV protective cap layer for extended exposure | UV sensitive – requires a UV protective cap layer for extended exposure |

PS(Polystyrene) | Clear plastic, very moldable, inexpensive, recyclable, high chemical resistance, high electrical resistance, heat distortion ~200°F | Cracks and breaks easily | Disposable cups, disposable applications, decorative applications, electrical applications |

HIPS (High Impact Polystyrene) | Very moldable, relatively inexpensive | Very moldable, relatively inexpensive | Picture frames, shower walls, food containers |

PVC (PolyvinylChloride) | Very high chemical resistance, stain resistant, stiffer than ABS, high room temp. impact strength, natural flame retardant qualities | Difficult to process | shower surrounds, moldings, kick panels, display cases |

Polycarbonate | Extremely high impact resistance, high clarity – good for transparent parts, precision molding, good insulator, high heat distortion point ~270°F | Low chemical resistance to certain substances (oil, gasoline, harsh chemicals), can be difficult to process, higher material and processing cost | Visors, plastic guards, transportation components (headlights, taillights, instrument panels), appliance drawers, skylights |

Polycarbonate/ABS | When compared to true polycarbonate – less expensive, lower heat distortion ~240°F, much easier to process, higher chemical resistance | When compared to true polycarbonate – reduced clarity, lower heat distortion ~240°F | When compared to true polycarbonate – reduced clarity, lower heat distortion ~240°F |

PETG (polyethylene- terephthalate) | Very easy to process, high clarity – good for transparent parts | Not UV stable – unsuitable for extended exposure | Structural automotive parts, hand tools, industrial components |

Certifications

DITAI Company is the vacuum forming factory which is verified by ISO and SGS company. Also our have the patent for our own vacuum forming technology!

Company Profie

Dongguan Ditai Plastic Products CO.,Ltd

Welcome To Ditai Vacuum Forming. We are a large plastics manufacturer, specializing in all kinds of vacumm formed OEM products and custom parts.

Our Engineers have more than 20 years experience in the industry and we are able to design, develop and produce all elements in-house; from design and tooling/moulds, to forming and CNC cutting. We are even able to carry out complex assembly of the final product for you.

Keeping all aspects in-house allows us to maintain unparallelled quality control as well as speeding up the entire process from concept to product delivery. Clients also benefit from us being a single point of contact for all your manufacturing needs.And we are so proud of our large volume machines, we have the largest vacuum forming machine in Guangdong! That being said, noproject is too small, and we will hapilly speak with you about how we can help you with your project requirements.

Keeping all aspects in-house allows us to maintain unparallelled quality control as well as speeding up the entire process from concept to product delivery. Clients also benefit from us being a single point of contact for all your manufacturing needs.And we are so proud of our large volume machines, we have the largest vacuum forming machine in Guangdong! That being said, noproject is too small, and we will hapilly speak with you about how we can help you with your project requirements.

Ditai factory Equipments

Over the past 7 years,we have invested several million dollars in equipment for our 4500 square meter manufacturing facility.This investment in equipment means that we can manufacture more custom parts, with higher quality results and in less time than the competition.

Extrusion forming machine

Aluminum Mold CNC Machine

Two Mold Making Machine Here. The vacuum forming mold will be produced by ourselves to keep high quality.

Ditai Mold Room

if you choose us for making the mold. It will have warranty service forever!

Vacuum Forming Machine

There are with 10 sets vacuum forming machine in our factory. To make sure delivery time for you is in time!

Automatic Vacuum Forming Machine

This vacuum forming is controlled by computer! High efficiency! Suitable for making big orders!

Dust Free Work Shop

For producing PETG, PC and some transparent products. It can make the transparent product more beautiful!

CNC Machine

There are 12 sets 180 degree CNC machine in our factory. The work capacity each day is around 500pcs!

360Degree/5Axis CNC machine

We have 3 sets 360 Degree CNC machine, it can work for any degree CNC Job!

Rotary Factory

We have other factory which is specialized in producing rotational products.

How To Order

Our standard manufacturing steps for OEM vacuum thermoformed plastic shell, same as our other products :

* 1.Customers provide 3D design drawing or sufficient info ( leng x widht x highx thickness, material, colors etc).

* 2.We offer quotation in time.

* 3.Once confirmed price,we prepare PI or contract.

* 4.After PI & contract confirmed, client transfer 50% deposit to us. We arrange to build mold according to customer's design

drawing.

* 5.Make samples for customer approved.

* 6.Arrange mass production after sample approved by customers.

* 7.Timely complete production .

* 8.Packing & delivery preparation.

* 9.On-time delivery after balance payment received.

* 10.B/L & other related documents send to clients once available.

* 1.Customers provide 3D design drawing or sufficient info ( leng x widht x highx thickness, material, colors etc).

* 2.We offer quotation in time.

* 3.Once confirmed price,we prepare PI or contract.

* 4.After PI & contract confirmed, client transfer 50% deposit to us. We arrange to build mold according to customer's design

drawing.

* 5.Make samples for customer approved.

* 6.Arrange mass production after sample approved by customers.

* 7.Timely complete production .

* 8.Packing & delivery preparation.

* 9.On-time delivery after balance payment received.

* 10.B/L & other related documents send to clients once available.

more products

Feedback

In Ditai, from 3D picture to the final product. you will find we all have the related machine and workman.Choose us, you will receive one stop service!

FAQ

1,What is vacuum forming or thermoforming?

Thermoforming is a generic term for the process of producing plastic parts from a flat sheet of plastic under temperature and pressure. In the highest expression of the technology, thermoforming offers close tolerances, tight specifications, and sharp detail. When combined with advanced finishing techniques, high-technology thermoforming results in products comparable to those formed by injection molding. All of us are exposed to many thermoformed plastics in our daily lives. They have replaced many parts previously manufactured from wood, paper, glass, and metal.

2, How do i pay?

For samples,you can pay via T/T, Westerm Union,Paypal,etc.

For mass production,50% T/T deposit,50%balance or L/C.

3, IF you still have more quetions......

Dear please don"t hesitate to contact us.

Thermoforming is a generic term for the process of producing plastic parts from a flat sheet of plastic under temperature and pressure. In the highest expression of the technology, thermoforming offers close tolerances, tight specifications, and sharp detail. When combined with advanced finishing techniques, high-technology thermoforming results in products comparable to those formed by injection molding. All of us are exposed to many thermoformed plastics in our daily lives. They have replaced many parts previously manufactured from wood, paper, glass, and metal.

2, How do i pay?

For samples,you can pay via T/T, Westerm Union,Paypal,etc.

For mass production,50% T/T deposit,50%balance or L/C.

3, IF you still have more quetions......

Dear please don"t hesitate to contact us.

Share

Share

Customer Reviews total 0 items