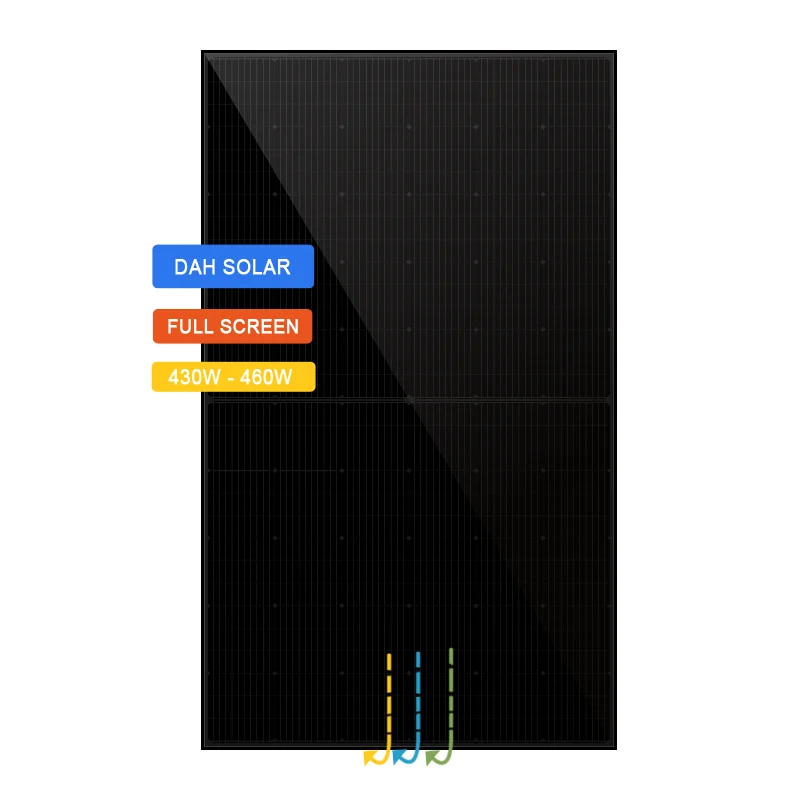

Covers 58,000 sqm and has 350 employees. DAH solar is a national high-tech enterprise specializing in R & D and manufacturing of solar modules, have own engineer team for complete set solar system design for residential and commercial projects.

Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

Product Details

Product Description

Maximum Power(Pmax) | 520W | 525W | 530W | ||

Open-circuit Voltage (Voc) | 49.0V | 49.2V | 49.4V | ||

Maximum Power Voltage(Vmp) | 41.2V | 41.4V | 41.6V | ||

Short-circuit Current (Isc) | 13.42A | 13.48A | 13.54A | ||

Maximum Power Current (Imp) | 12.62A | 12.68A | 12.74A | ||

Solar Panel Efficiency | 20.12% | 20.31% | 20.51% | ||

Power Tolerance | 0~+5W | ||||

Standard Test Environment | Irradiance 1000w/m2, Ambient temperature 25℃, Spectrum AM 1.5 | ||||

Maximum Power(Pmax) | 535W | 540W | 545W | 550W | |||

Open-circuit Voltage (Voc) | 49.6V | 49.8V | 50.0V | 50.2V | |||

Maximum Power Voltage(Vmp) | 41.8V | 42.0V | 42.2V | 42.4V | |||

Short-circuit Current (Isc) | 13.60A | 13.66A | 13.72A | 13.78A | |||

Maximum Power Current (Imp) | 12.80A | 12.86A | 12.91A | 12.97A | |||

Solar Panel Efficiency | 20.70% | 20.89% | 21.09% | 21.28% | |||

Power Tolerance | 0~+5W | ||||||

Standard Test Environment | Irradiance 1000w/m2, Ambient temperature 25℃, Spectrum AM 1.5 | ||||||

Automatic Production

DAH solar - established in 2009 with 1.5GW solar module production capacity

Solar cell Welding

Use automatic welding machine to connect solar cells in series

All the solar cells are made by top class brand, like TW Solar, Longi Solar

Automatic typesetting machine

After setting up the program according to the requirements of the process drawings, the typesetting machine will automatically typeset the battery string. High precision, high efficiency, low defect rate

Automatic laying of EVA, backing, automatic cutting of excess backing material

100% automation of the entire production process

Use the mirror to inspect the appearance of the solar modules before lamination, and repair them if they are defective;

Through the turning machine, completely inspect the solar panel after lamination, and record the defects and feedback to the previous process

Including temperature, power, voltage, current and other related tests, ensure 0~+5W Positive Power Tolerance

Packing & Delivery

Solar Projects

Service Team

Related Products

Share

Share

Customer Reviews total 0 items