Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

Product Details

Typical Applications:

• UV gluing, UV curing, UV marking

• UV drying of printing inks and lacquers

• Currency inspection

• Detects fluorescing minerals and gems

• Indoor/ Outdoor Lighting

Features:

• Well-known chip material, EPILEDS

• 99.99% gold wire bonding

• High flux per LED

• Industry best moisture sensitivity

• Low-temp & lead free reflow soldering

• More energy efficient than incandescent and most halogen lamps

• Low Voltage DC operated

• Instant light(less than 100ns)

• RoHS, CE compliant

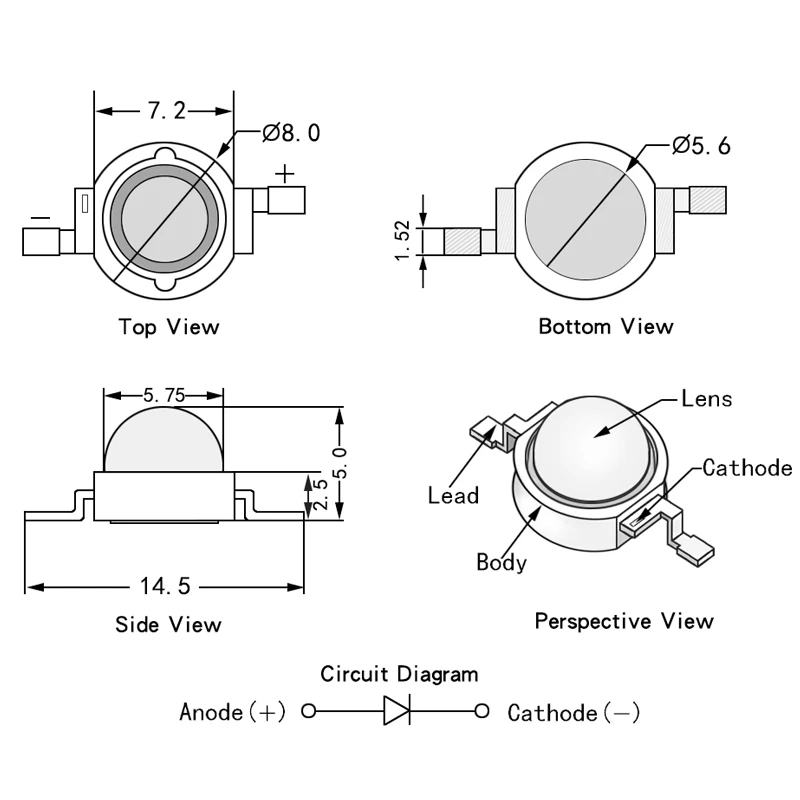

Emitter Mechanical Dimensions

Notes:

1. The Cathode side of the emitter is denoted by "-" Sign in the lead frame.

2. Electrical insulation between the case and the board is required. Do not electrically connect either the anode or cathode to the slug.

3. Drawing not to scale.

4. All dimensions are in millimeters.

5. Unless otherwise indicated, tolerances are ± 0.2mm.

6. Please do not bend the leads of the LED, otherwise it will damage the LED.

7. Please do not use a force impact or pressure on the lens of the LED, otherwise it will cause a catastrophic failure.

| Part No. | Power (W) |

Emitting Color |

Color Wavelength (NM) |

Radiant Power (mW) |

Forward Voltage (V) |

Forward Current (mA) |

| JH-3V14G45-T2A-370 | 1-3W | UV LED | 360-370NM | 1000-1200mW | 3.0-3.4V | 700mA |

Flux Characteristics at 700mA, Temperature=25℃

| Radiation Pattern | Part Number | Color | Radiant Power(mW) | |

| Min | Max | |||

| Lambertian | JH-3V14G45-T2A-370 | UV LED | 1000mW | 1200mW |

• LEDGUHON maintains a tolerance of ±5% on flux measurements.

• Please do not drive at rated current more than 1 second without proper heat sink.

Optical Characteristics at 700mA, Temperature=25℃

| Color | Dominant Wavelength | Viewing Angle | ||

| Min | Typ | Max | ||

| UV LED | 360NM | 365NM | 370NM | 140° |

• LEDGUHON maintains a tolerance of ±1nm for dominant wavelength measurements.

Electrical Characteristics at 700mA, Temperature=25℃

| Color | Forward Voltage | ||

| Min | Typ | Max | |

| UV LED | 3.0V | 3.2V | 3.4V |

• LEDGUHON maintains a tolerance of ±0.1v for voltage measurements

Absolute Maximum Rating

| Parameter | UV LED |

| DC Forward Current(mA) | 700mA |

| Peak Pulsed Forward Current(mA) | - |

| Reverse Voltage(V) | - |

| Viewing angle(°) | 140° |

| Chip Material | InGaN |

| Lens Color | Water Clear |

| Storage Temperature(℃) | -35℃ - 85℃ |

| Operating Temperature(℃) | -35℃ - 85℃ |

| LED Junction Temperature(℃) | 120℃ |

| Working lifespan | 30000-50000 Hours Normally |

360-370NM UV LED Spectrum Representation, Temperature=25℃

Forward Current Characteristics, Temperature=25℃

1. Forward Voltage vs Forward Current

2. Forward Current vs Normalized Relative Luminous Flux

Recommended Solder Pad Design

• All dimensions are in millimeters.

• Electrical isolation is required between Slug and Solder Pad.

Soldering Conditions

• When soldering High Power Led, Heat may affect the electrical and optical characteristics of the LEDs.

• In soldering, do not stress the lead frame and the resin part under the high temperature.

• The silicone part should be protected from mechanical stress or vibration until the High Power Led return to room temperature after soldering.

• Preliminary heating to be at 140˜160℃ max, for 120 seconds max.

• Soldering heat to be at 260℃ max, for 3 seconds max.

• For manual soldering is not more than 3 seconds at max 260℃, under soldering iron.

Storage

• Before opening the package, the LEDs should be kept at 30℃ or less and 70%RH or less.

• The LEDs should be used within one year.

• After opening the package, the LEDs should be kept at 30℃ or less and 30%RH or less.

• The LEDs should be used within one month after opening the package.

• If the moisture absorbent material(silicone) has fade away or the LED have exceeded the storage time, baking treatment should be performed using the following conditions. Baking treatment: 60℃±5℃ for 48 hours.

Static Electricity

• Static electricity or surge voltage damages the High Power LED. It is recommended that a wrist band or an anti-electrostatic glove be used when handing the LEDs.

• A tip soldering iron is requested to be grounded, An ionizer should also be installed where risk of static.

• All devices, equipment and machinery must be properly grounded, It is recommended that measures be taken against surge voltage to the equipment that mounts the High Power LED.

Cleaning

• Isoprophy Alcohol or Ethylene Alcohol is recommended in 5 minutes at room temperature. Do not use unspecified chemical may cause crack or haze on the surface of the epoxy resin.

• Before cleaning, a pre-test should be done to confirm whether any damage to the LED will occur.

• Freon solvent should not be used to clean the LEDs because of worldwide regulations.

Heat generation

• When the LEDs are illuminating, operating current should be decided after be considering the ambient maximum temperature.

• Please consider the heat generation of the LED when it is designed the PCB.

• The LEDs must be mounted on metal core PCB or heat sink or applied thermal pad.

Handing LED

LEDGUHON recommends the following at all times when handing LEDs or assemblies containing the these LEDs:

• When handing the LED with tools like Tweezer or Nipper, do not apply Mechanical Forces directly on LED's Surface.

• Do not touch with hand LED Lens surface directly. It may contaminate the Lens surface and affect on optical characteristics.

• LED should be handled from side because LED's molding material may be damaged with scratching on surface, piercing molding material and broking wire.

Attention: Electric Static Discharge (ESD) Protection

Option 1 - Tube Packing

Option 2 - Tape Reel Packing - (*Default Option*)

Notes:

1. Drawing not to scale.

2. All dimensions are in millimeters.

3. Unless otherwise indicated, tolerances are ±0.2mm.

• Please do not open the moisture barrier bag(MBB) more than one week. This may cause the leads of LED discoloration. We recommend storing LEDGUHON's LEDs in a dry box after opening the MBB. The recommended storage conditions are temperature 5-30℃ and humidity less than 40% RH.

1. Is there any discount for bulk order?

Yes, if you need bulk order or you want customized products, we can provide wholesale price.

2. How to place an order?

If you want to place an order, Please feel free to send us an inquiry email, we will reply you within 24 hours (working day).

3. What payment terms are available?

T/T, Western Union and PayPal are preferred.

4. Do you support drop shipping and how much is the shippping cost?

Yes, we support drop shipping. You should leave the receiver's information when you place the order, then we will send the goods according the address you have left. The shipping cost are based on your order's volume and weight, and it can be calculated.

5. All the pictures are real photo?

Yes, the pictures of all products on this page are 100% real shoot by us.

6. How about the quality of 3W UV LED?

Please do not worry about the quality. Our company is the main manufacturer of 3W UV LED in China. Our products have exported worldwide since the year 2009.

7. Is there any custom duty and import tax?

Due to different policy in different countries, there might be some custom duty and import tax, but it is not considered in the price and should be paid by yourself. We are not responsible for any custom duty and import tax.

If you need more type of other High Power LED, Please find it on our website:

Share

Share

Customer Reviews total 0 items