Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

Product Details

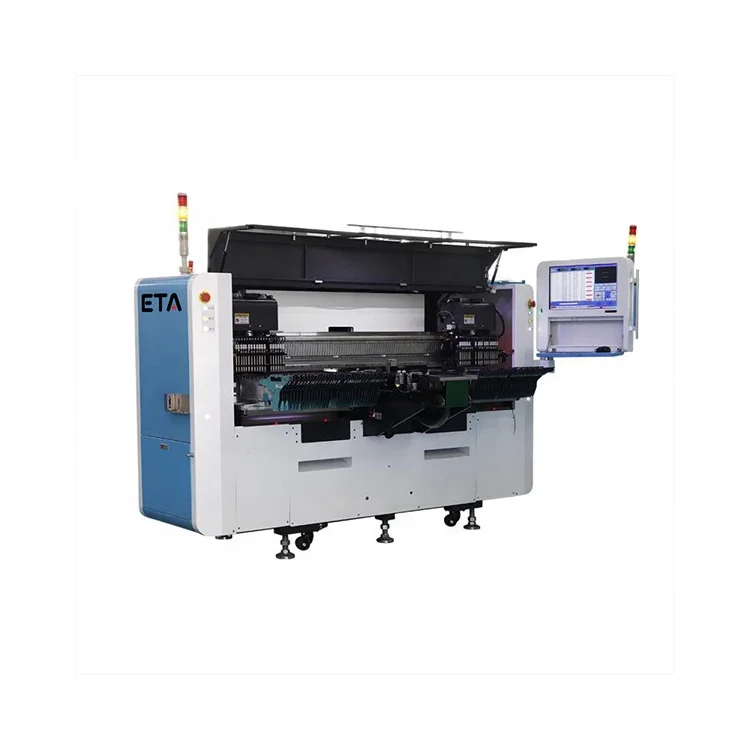

ETA LED Reflow Oven for Lamp Panel Lights Production Line

Products Description

ETA Lyra series lead-free reflow oven ETA’s mature product after years of market testing. Lyra Series Reflow oven has maintained a larger share of the market for many years. Its unparalleled heating performance and temperature control system meets the requirements of various welding processes. It is ETA’s crystallization of years technical research and development. Lyra Series Lead-free reflow is high-end reflow products committed to keeping up with market demand to enhance customers competitiveness.Its new design concept fully meets the needs of increasingly diverse processes. And considering the future direction of the industry, entirely suitable for communications,automotive electronics, home appliances, computers and other consumer electronic products .

Features:

1.Control System: PC + Siemens PLC control system,accurate temperature control and more stable,ensures temperature stability rate to be more than 99.99%. 2.Hot air system: first-class heating module, the best temperature zone interval design makes optimum temperature uniformity and repeat.The effective utilization and thermal compensation efficiency,it needs less than 20 minutes from temperature control accuracy ± 1 ℃ ambient temperature to a temperature stabilization .

3.Monitoring Software:Windows interface, traditional and simplified Chinese and English online free switch, and operator password management, easy to operate.Operation records, temperature curve measurement and analysis functions, virtual simulation, fault self-diagnosis, process monitoring, automatic generate and save process control documents, substrate transport dynamic display.

4.Cooling System: new cooling zone, quick and easy adjustment, easily reach the cooling requirements of different slopes.

5.Temperature protection:ETA using third-party over-temperature protection, multiple layers protection to ensure safe operation.

6.Products comply with CE, CCC, UL , other standards and specifications.

7.User-friendly design: fault detection (such as heaters abnormal alarm, etc.), regular maintenance reminders, the economy functions and tool-free maintenance, reducing equipment failure rates.

8.Heating module: Transverse reflow design makes temperature from each zone is not influenced by neibour to ensure accurate temperature curve, while ensuring a high production capacity and heat exchange capacity to achieve high adaptability (to meet the soldering of automotive, communications, electronics, computers and mobile phones consumer electronics.)

9.Hot air motor with independently inverter controlled, set operating frequencies depending on different technology to meet a variety of lead-free processes.

10. Machine using zero gas source design, furnace cover with motor lifting, safety rod support, providing significant security.

11.Main parts:Imported main parts ensure equipment runs smoothly and lower the maintenance cost.

12. Customers can choose optional flux processing system according to their own production features to ensure furnace chamber clean.

13.Closed-loop transmission speed control systems, transportation accuracy ± 2mm / min, ensuring more stable transmission speed.

14.Central support, dual transmission, external water cooling system is optional.

Success Cases of ETA's Overseas Customers

ETA is a leading provider of factory planning solution. we have 3 wholly-owned factories, providing professional

consultation and services for global customers. We have more than 22 years of electronic industry experience,through our superior resources in China to provide global customers with systematic overall solutions. We not only

provide a complete set of equipment, but also provide full range of technical support and services, and give

customers more reasonable professional advice. We help many customers to set up factories in led, tv, mobile phone,

dvb, ems and other industries all over the world. We are trustworthy.

ETA core technology team has more than 22 years of experience in SMT/DIP technology, providing customers with

more SMT/DIP solutions.

ETA's after-sales service team has more than 15 years of SMT service experience and more than 10 years of overseas

after-sales service experience, and its service scope is all over the world.

ETA also offer full solution/Turnkey solution for customers as below

TOP Advantage:

1.Simple: combined with advanced international concepts, based on the Oriental-designed operating system, easy to understand, easy to learn, easy to maintain.

2.Expertise: learn imported reflow oven’s advanced design concepts, and the machine core components are using imported top brands.

3.Hedging: Import hardware configuration,low failure rate in production,more than a decade service life.

4.Safety: Based on the general rules of international design, close to imported reflow rating, the highest security level.

5.Stable: mature software, hardware and top production processes ensures stability of each equipment.

3.Hedging: Import hardware configuration,low failure rate in production,more than a decade service life.

4.Safety: Based on the general rules of international design, close to imported reflow rating, the highest security level.

5.Stable: mature software, hardware and top production processes ensures stability of each equipment.

Specification

Specifications | Lyra622 | Lyra733 | |

Dimension (L*W*H)mm | 5040x1450x1450 | 5800x1450x1450 | |

Weight | Approx.2200KG | Approx.2400KG | |

Number Of Heating Zones | Up8/Bottom8 | Up10/Bottom10 | |

Length Of Heating Zones | 3030mm | 3730mm | |

Exhaust Volume | 10M3 /minx2 Exhausts | ||

Conveyor Direction | L→R (Option: R→L) | ||

Related Products

Company Profile

ETA is the leading SMT factory solution provider in China ,offering professional SMT factory building advice and service.We have 22 years experience about SMT factories,offering full solution for global clients with our advantaged sources in China. Our core technology team members are all from Foxconn,Huawei,Siemens and other companies,we not only provide a full set of equipments,we also provide full smt technical support and services,Besides we give customers more reasonable and professional suggestions.We have already helped many customers to establish factories in LED, TV, Phone, DVB, EMS and other filed around the world ,we are worthy of trust!

Main Products: SMT LED Pick and Place Machine,SMT LED Reflow Oven,SMT LED Stencil Printer,SMT Production Line,LED Assembly Line,SMT LED Machine.

Successful Experience:

1.We have been helping customers to build a lot of new factories around the world.

2.Training more than 500 experts and technician for customers.

3.Became the most reliable Chinese partner for you.

Main Products: SMT LED Pick and Place Machine,SMT LED Reflow Oven,SMT LED Stencil Printer,SMT Production Line,LED Assembly Line,SMT LED Machine.

Successful Experience:

1.We have been helping customers to build a lot of new factories around the world.

2.Training more than 500 experts and technician for customers.

3.Became the most reliable Chinese partner for you.

Our Service

A. Pre-consultation:provides professional SMT solution for the full line.

B. Factory Warranty:One-year warranty factory service.

C. Installation:On-site installation and commissioning,to ensure smooth production.

D. Technical Training:provides professional training from level 1 to level 3.

E. Technical Support:provides 7 days * 24 hours technical support.

F. Software Upgrade:offers lifetime free software upgrades from all products.

B. Factory Warranty:One-year warranty factory service.

C. Installation:On-site installation and commissioning,to ensure smooth production.

D. Technical Training:provides professional training from level 1 to level 3.

E. Technical Support:provides 7 days * 24 hours technical support.

F. Software Upgrade:offers lifetime free software upgrades from all products.

Certifications

Product packaging

Share

Share

Customer Reviews total 0 items