Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

Product Details

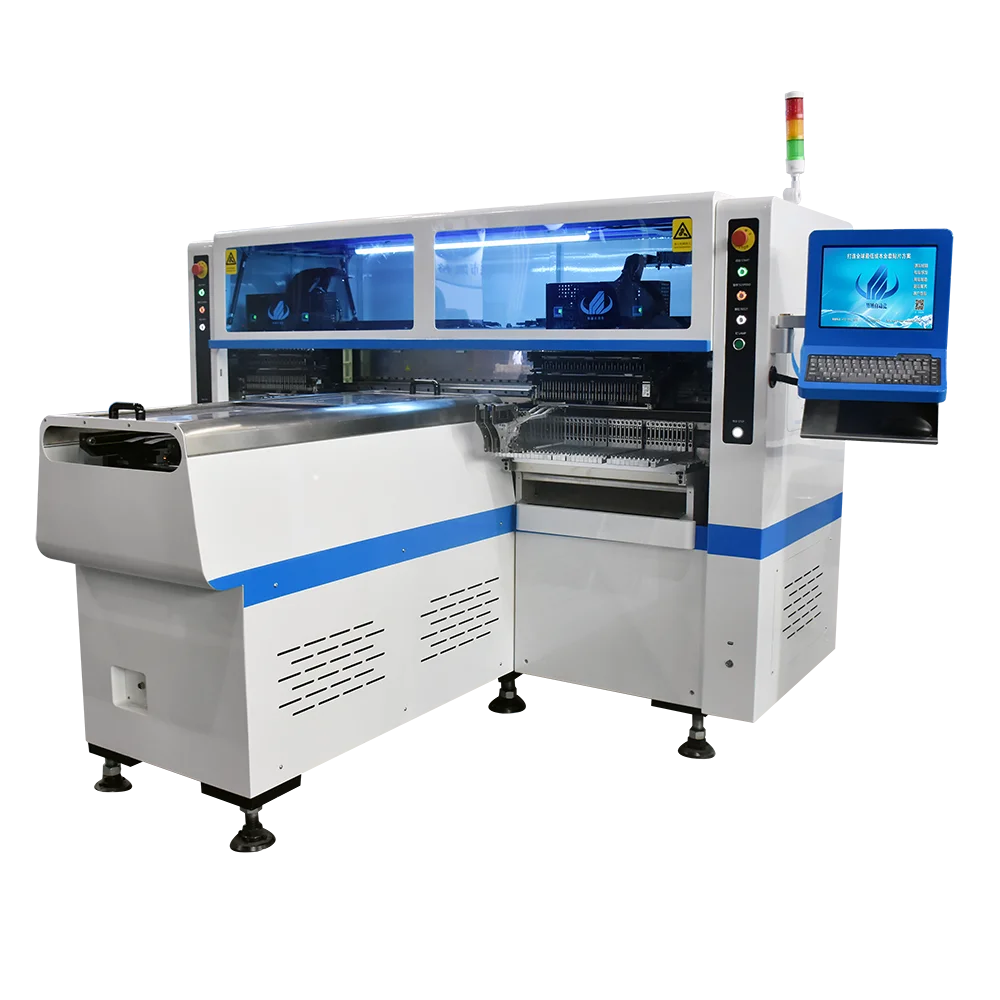

HT-F9 professional high speed mounter can producing with 2~4 types of materials with high capacity,available for board with any proportion of LED chip and resistors.

Two mounting modules ,18 nozzles for each mounting part, part A or B can be mounted separately or synchronously.

Special LED mounter

apply to the 0.6m,0.9m.102mLED rigid PCB and0.5m,1m flexible strip.

Visual system

5 sets of imported camera

Vision alignment ,mark correction

The imported camera can accurately identify the exact position of PCB board and the position of components and board. The overlooking camera searches for the target on the circuit board (as a benchmark) in order to place the circuit board in the correct position before assembly, and the overlooking camera is used to detect elements in the fixed position.

Maximize Time Saving and Improve Production Efficiency

The products to be mounted can cover the whole platform and realize the cycle production.

The camera is installed between the pickup position and the installation position. The acquisition and processing of the video can be carried out simultaneously during the movement of the installation head to shorten the installation time.

High Speed and High Precision

This special Mounter has a speed of 150000~170000 CPH.Can save space, labor costs, management costs

No. Of feeder station:34PCS nozzles:34PCS

It has a set of vision recognition system, which can process the absorbed components into the required mounting angle through image recognition, and realize high precision mounting, with an accuracy of 0.02mm.

Good durability

Using High Stability Electronic Dual Motor

The wear resistance of screw rod is not easy to deviate and has high accuracy.

The guide rail has strong bearing capacity and high stability.

High-quality hardware configuration for 24-hour machine operation.

|

HT-F9 |

||

|

PCB |

PCB length width |

Max:1200*330mm min:80*330mm |

|

PCB thickness |

0.5~5mm |

|

|

PCB clamping |

Adjustable pressure pneumatic |

|

|

Mounting mode |

Group to take and group to mount |

|

|

O.S. |

system |

Windows 7 |

|

software |

R&D independently |

|

|

display |

Touch screen monitor |

|

|

Input device |

Keyboard , mouse |

|

|

Vision system |

No.of camera |

5 sets of imported camera Vision alignment,mark correction |

|

Mounting precision |

0.02mm(repeat precision) |

|

|

Mounting height |

<15mm |

|

|

Mounting speed |

200000CPH |

|

|

Components |

LED 3014/3020/3528/5050 and resistors,capacitors ,bridge rectifiers. |

|

|

Components space |

0.2mm |

|

|

No.of feeders station |

68PCS |

|

|

No.of nozzles |

68PCS |

|

|

Power |

380AC 50HZ |

|

|

Power consumption |

6KW |

|

|

Conveyor transmission |

Belt drive |

|

|

Transmission speed |

>500mm/sec |

|

|

Transmission direction |

Single (left to right or right or left) |

|

|

Transmission mode |

Auto online drive |

|

|

Position mode |

Optical |

|

|

Air pressure |

>5.0kg /cm² |

|

|

Electrical control |

Independent research and development by ETON |

|

|

Motion control card module 1set |

Independent research and development by ETON |

|

|

X,Y,X axis drive way |

Servo motor +magnetic linear motor |

|

|

Feeding way |

Electric feeder with double motor |

|

Applications

we will send our engineer to your factory to install machine and training freely.

We have service office in india,and have indian engineer in delhi and mumbai.Can support quickly.

Standard warranty is one year,during warranty,any parts need to be repaired and replaced will be free.

1.What’s the terms of payment? What about the trade term?

T/T is OK. You can choose FOB Shenzhen.

2.What is the delivery date?

We will deliver the goods after 30 days' deposit.

3.What mode of transport does the goods adopt?

Our mode of transportation is very flexible.Our mode of transportation including water, land and air transportation.You can choose the most suitable way according to your requirements.

4.What is the direction of transmission of machines?

The transmission direction of this machine is single direction.From left to right or from right to left.

5.How about your operating system?

The operating system is Windows 7. The software is developed independently. It supports Chinese and English operation interface. And It has simple structure and is easy to operate.

Share

Share

Customer Reviews total 0 items