elon Teams since 2003 engaged in battery business,Enterprises from the initial Ni-MH battery production extends to the production of lithium ion battery materials and battery . Most of the senior management staffs graduated from China's most famous electrochemical professional --CENTRAL SOUTH UNIVERSITY, from which created a lot of leaders in Chinese lithium ion battery industry such as Mr ChuanFu Wang(BYD),Mr XinDe Xia, Mr KaiHua Xu, Professor GuoRong Hu and XinHai Li Etc. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. Gelon Focus on manufacturing and selling of new materials (anode, cathode, separator, additive etc. ) for lithium ion battery, and also offer full sets of materials solution to customers. Our preponderant products are Lithium Iron Phosphate(LFP), Lithium Manganese Dioxide(LMO), Lithium Cobalt Oxide(LCO), Lithium Nickel Manganese Cobalt Oxide(NMC), Lithium Nickel Aluminum Oxide(NCA) ,Lithium Titanate Oxide(LTO) materials; Graphite materials (MCMB) , Separator & Other accessories (SBR CMC NMP PVDF,Sup-Li,Al&Ni Tabs )etc for new power lithium ion batteries. Meanwhile, we have our own lithium ion battery factory who mainly produces lithium ion battery for camera, mobile, EV application. Based on our battery production line, we can offer all services (Raw Materials, Equipments, Production line design &Technology, etc. ) for full set of equipments to help clients to set up Lab & Pilot line for lithium ion battery. Bynow, Gelon have finished many turn key project in Bolivia,Indonesia, Indian, Russia,Turkey and South Africa We have a more than ten years professional and experienced exporting teams to supply perfect services for all our customers. We are confident on our quality and service.And ensure to offer the best services based on our specialty and empressement. Our Aim is to be the comprehensive company dealing with One-Stop services for Lithium ion battery in the world. Our Business Philosophy: You choose us, We promise you What we offer to you,are what we are using Integrating the quality resources in China, delivering the best service and products to you. The best product we can provide, is our sincerity and reliability.

| Business Type | Manufacturer, Trading Company | Country / Region | |

| Main Products | | Ownership | |

| Total Employees | | Year Established | |

| Certifications | | Product Certifications | |

| Patents(3) | | Trademarks | |

| Main Markets | | | |

Factory Information

Factory Size | 1,000-3,000 square meters |

Factory Country/Region | Room 1606, Jinding International, Lanshan District, Linyi City, Shandong Province, China |

No. of Production Lines | |

Contract Manufacturing | OEM Service Offered, Design Service Offered |

Annual Output Value | |

Annual Production Capacity

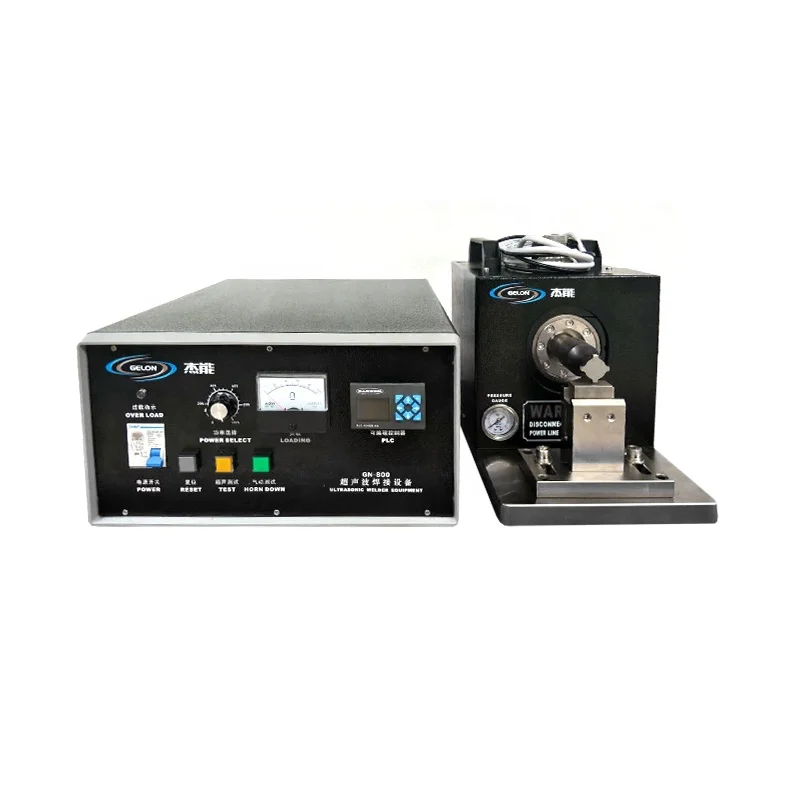

Lithium Battery Equipment | 30 Sets / Month | confidential |

|

Main Markets & Product(s)

North America | 20.00% | Lithium Battery Materials; Lithium Battery Equipments/Lithium Battery Lab Equipments/Lithium Ion Battery Production Line |

|

South America | 15.00% | Lithium Battery Materials; Lithium Battery Equipments/Lithium Battery Lab Equipments/Lithium Ion Battery Production Line |

|

Eastern Europe | 15.00% | Lithium Battery Materials; Lithium Battery Equipments/Lithium Battery Lab Equipments/Lithium Ion Battery Production Line |

|

Southeast Asia | 10.00% | Lithium Battery Materials; Lithium Battery Equipments/Lithium Battery Lab Equipments/Lithium Ion Battery Production Line |

|

Oceania | 10.00% | Lithium Battery Materials; Lithium Battery Equipments/Lithium Battery Lab Equipments/Lithium Ion Battery Production Line |

|

Mid East | 5.00% | Lithium Battery Materials; Lithium Battery Equipments/Lithium Battery Lab Equipments/Lithium Ion Battery Production Line |

|

Eastern Asia | 5.00% | Lithium Battery Materials; Lithium Battery Equipments/Lithium Battery Lab Equipments/Lithium Ion Battery Production Line |

|

Western Europe | 5.00% | Lithium Battery Materials; Lithium Battery Equipments/Lithium Battery Lab Equipments/Lithium Ion Battery Production Line |

|

Central America | 4.00% | Lithium Battery Materials; Lithium Battery Equipments/Lithium Battery Lab Equipments/Lithium Ion Battery Production Line |

|

South Asia | 4.00% | Lithium Battery Materials; Lithium Battery Equipments/Lithium Battery Lab Equipments/Lithium Ion Battery Production Line |

|

Northern Europe | 3.00% | Lithium Battery Materials; Lithium Battery Equipments/Lithium Battery Lab Equipments/Lithium Ion Battery Production Line |

|

Southern Europe | 2.00% | Lithium Battery Materials; Lithium Battery Equipments/Lithium Battery Lab Equipments/Lithium Ion Battery Production Line |

|

Africa | 1.00% | Lithium Battery Materials; Lithium Battery Equipments/Lithium Battery Lab Equipments/Lithium Ion Battery Production Line |

|

Domestic Market | 1.00% | Lithium Battery Materials; Lithium Battery Equipments/Lithium Battery Lab Equipments/Lithium Ion Battery Production Line |

|

Trade Ability

| Language Spoken | English |

| No. of Employees in Trade Department | 11-20 People |

| Average Lead Time | 20 |

| Export License Registration NO | 04557722 |

Business Terms

| Accepted Delivery Terms | FOB, EXW, FCA |

| Accepted Payment Type | D/P D/A |

| Nearest Port | QINGDAO, SHANGHAI, SHENZHEN |

Customer Reviews total 0 items