Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

Product Details

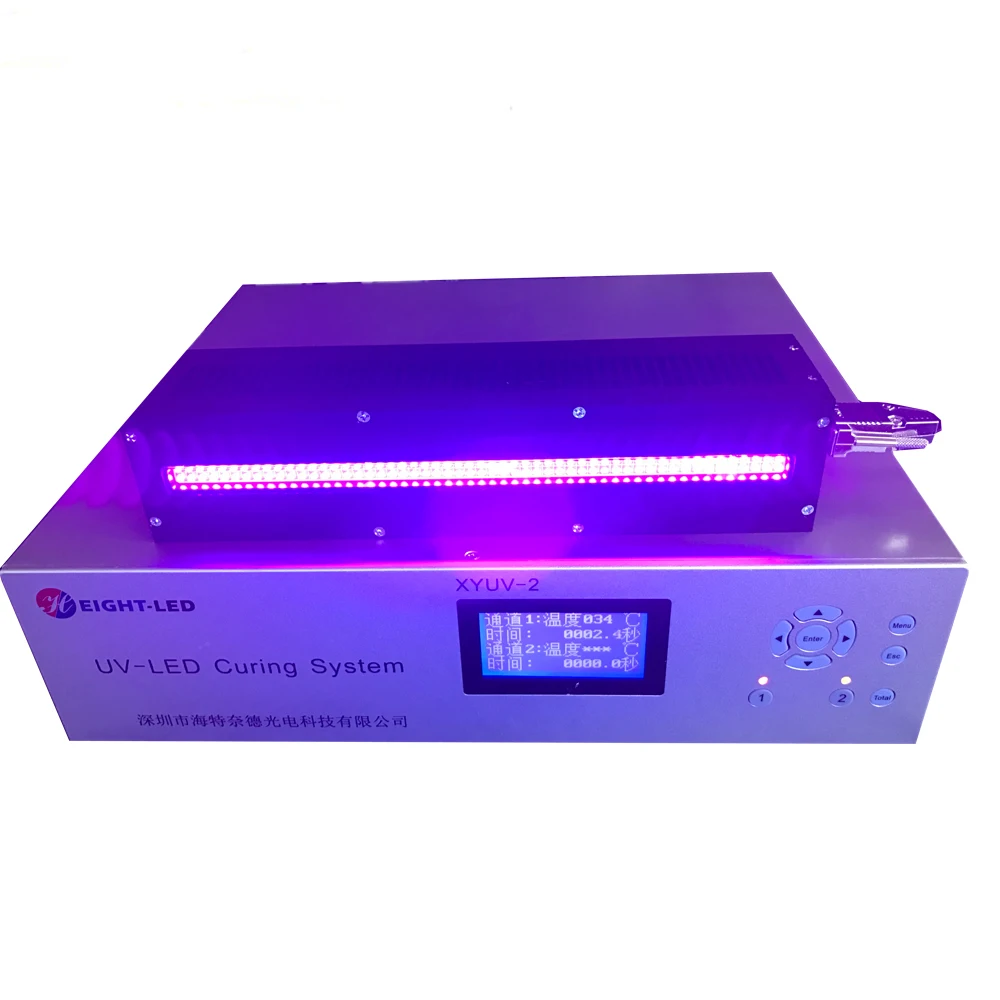

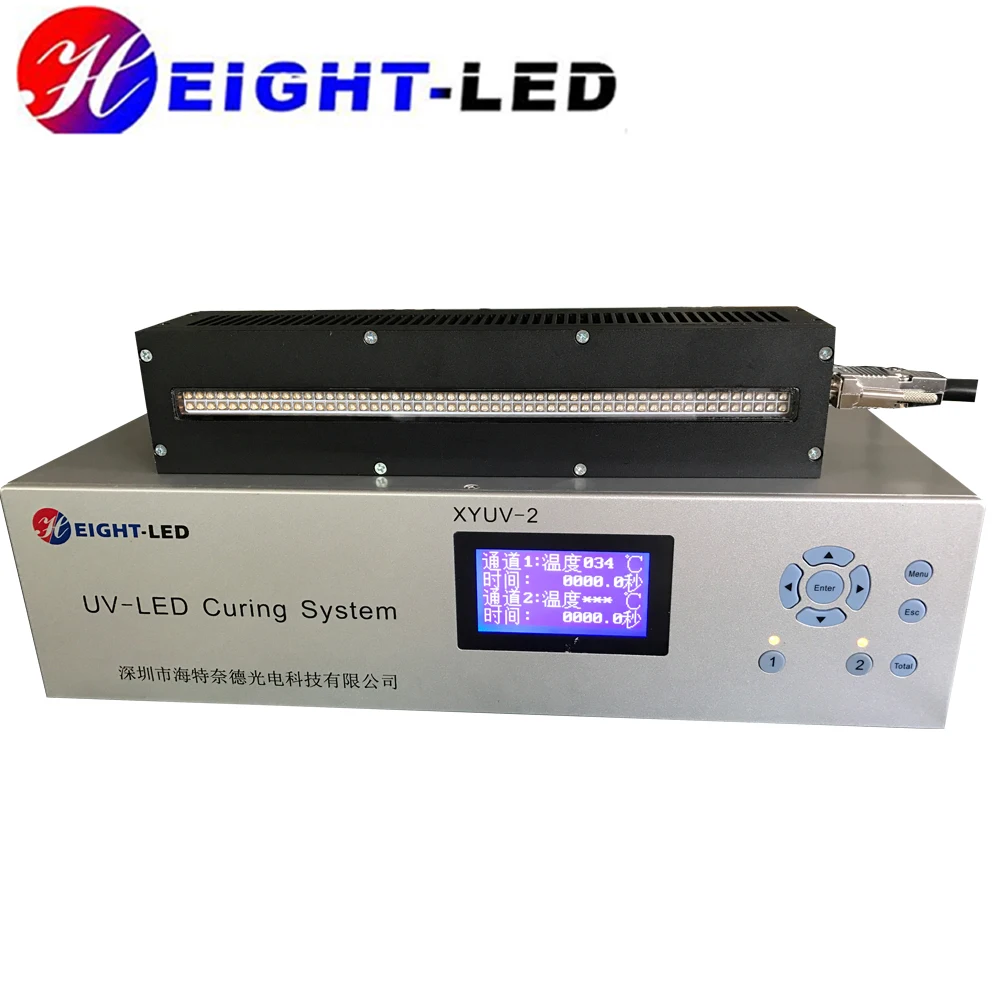

Guangdong HTLD 100w array 365 nm 385 395 405 available high intensity UV LED curing Linear light

HTLD UV LED curing machine contain two parts: Controller and Irradiation Head.

Controller technical specifications | |||

| Type | HTLD-4II | ||

| Channel | Four | ||

| The size of controller | L185*W100*H125mm | ||

| Terminal I/O | Input | Pedal switch & serial RS-232 communication signals | |

| Output | serial RS-232 communication signals | ||

| Cooling method of controller | Air cooling | ||

| Power supply voltage | AC100~240V±10%(50/60HZ) | ||

| Operation mode | push button control | ||

| Ambient temperature and humidity | Ambient temperature:-10℃—50℃ Relative humidity:25%—85%RH | ||

| Dimming/Exposure control | Digital Debugging,Manual exposure control,Foot control or timing control (0.1~9999S) | ||

| Setting operation | Using the operating switch is set,Power key parameter switch,RS-232 | ||

| External Control | External input | Enter irradiation alone Irradiation stop input, Interlocking,All lights illuminated input,Query switch | |

| External output | READY signal,Error +5VOutput (indicator used) | ||

| ||

| type | HTLD-L54-10X250 | |

| Electric power | 300W | |

| Cooling method | Air cooling | |

| Curing area | 10x250mm | |

| Irradiate distance | 10~100mm | |

| UV LED curing head | wavelength | 365-405nm or customized |

| Peak irradiance | 2000mW/CM2 | |

Other size could be customized | ||

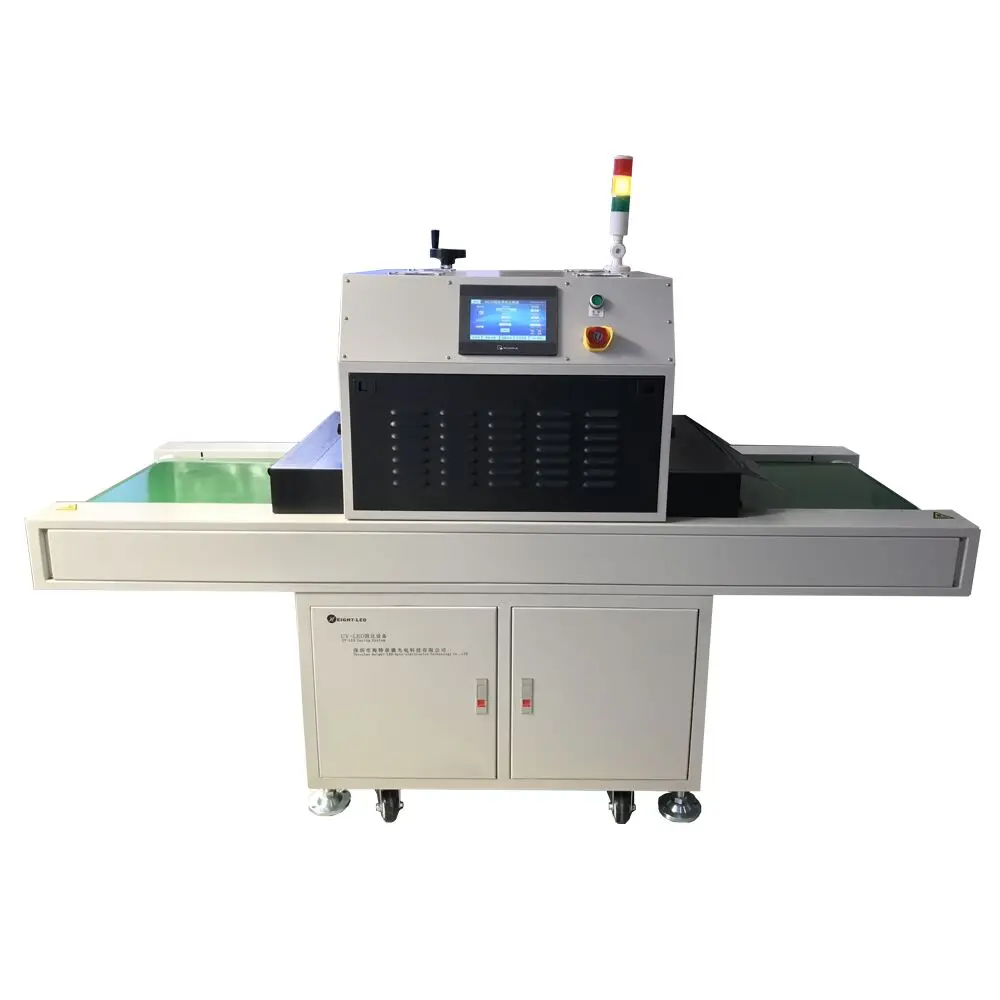

HTLD-L54-10x250 is a high quality UV LED linear light source curing system, the system includes the controller, UV LED irradiation head . UV LED head with imported high-intensity UV LED integrated UV spectral wavelength of 365nm, 385nm, 395nm, 405nm, the effective curing area of 10x250mm, support for external signal input and trigger, can be equipped with semi-automatic or fully automated production line . It can be used to cure different materials,such as UV glue, UV ink, UV varnish, UV paint.

| 1: Height LED have real factory, professional engineers with over 7 years experience and skilled workers |

| 2: We have over 12 years experience in LED UV curing industry |

| 3: We has established good reputation and high quality position and it supplies high quality UV LED lights. |

| 4: We have professional R&D team and one year free warranty |

| 5: 7*24 hours Technical support |

| 6: Abundant Experience of Export |

| 1.Extra-long life: 25000h~30000h |

| 2.Energy saving: save 80% electrical energy than Mercury lamp |

| 3.UV output adjustment: From 1% to 100% |

| 4.Multiple control modes : Constant current, pedal control, intelligent optical and manual modes |

| 5: Photoelectric induction, instant on/off, no preheating required. |

| 6: Low energy consumption, just 20% of the ordinary uv lamp |

| 7: No mercury, No Ozone, eco-friendly |

| 8: Cold light source, low temperature |

| 9: Stable output, high uniformity. |

Shenzhen Height-LED Opto-electronics Technology Co., Ltd located in Shenzhen, Guangdong, China. Starting in 2007, Height-LED engaged in UV-LED curing UV ink, UV adhesive UV paint, UV varnish and other UV sensitive materials. Our team has more than 10 years combined experience in UV curing systems and can meet the requirements of each client.

| FAQ |

Q1: Why choose HTLD UV LED curing system?

A:The team has over 10 years combined experience in UV LED curing industry and can meet the requirements of each client.

Q2: What's the application of HTLD UV LED curing system ?

A:HTLD UV LED curing system can be used for curing UV glue, UV ink, UV adhesive, UV paint, UV varnish and other UV sensitive materials.

Q3: What is the major advantages of UV LED curing system’s than other UV curing system?

A:Extra-long life, energy saving and environment friendly.

Q4: Which wavelength do I need?

A:It depends on your UV sensitive materials.

Q5: What's the emitting window do I need?

A:It depends on your product’s size that need to be cure.

Q6: What's the Peak Irradiance do I need?

A:It depends on your UV sensitive materials and your Production efficiency.

Q7: The common emitting window and Peak Irradiance can not meet my requirements?

A:Do not worry! Any sizes of emitting window and Peak Irradiance can be customized .

Q8: Where is your company located?

A: 2/F, Towel B, Sanhe international science and technology Building, Da Lang Road,Long Hua District, ShenZhen, Guang Dong Province, China.

Q9: I do not know how to choose a set of uv led curing system.

A: Please click here.

Share

Share

Customer Reviews total 0 items