North America 50.00%

Western Europe 20.00%

Eastern Europe 10.00%

Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

Features

TMAX-556 is an economic desktop Vacuum Spin Coater without vacuum chunk which is designed for quality coating of sol-gel at the lowest cost. By using adhesive tape to stick and hold samples on the rotating plate, the instrument provides the advantages of cost effectiveness and ease of maintenance. Complete accessories such as vacuum chuck, oilless vacuum pump, electrical wire is included for immediately use.

Technical Parameter

|

Working Voltage |

220V AC selectable |

|

Structure |

· Heavy duty Aluminum casting case to keep spinning stable · 110VDC motor · Can not be used under Ar gas |

|

Spin Plates |

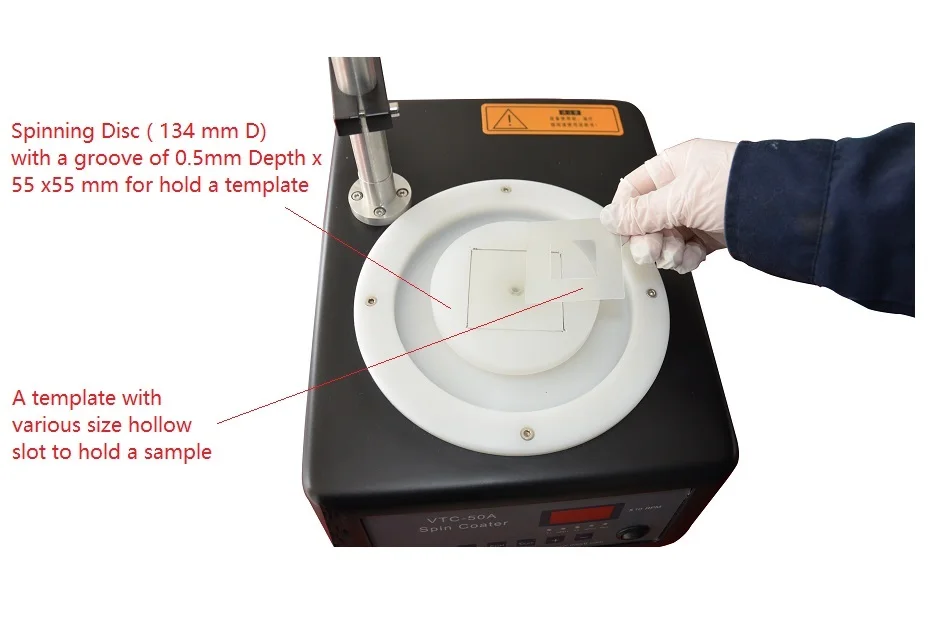

· Chamber size is 134mm diameter, can accept wafer sample 4" diameter at Max. · Two 4" stainless steel spin plates are included, which can hold one or multiple samples by wax or double-sided tape · One roll of 3M removable double-sided tape (3/4' W x 400" L) is included for immediate use (please click picture below to see specs and order spare tape) |

|

Spin Speed |

· Digital display with variable speed up to 8000 RPM · Digital control panel with two programmable segments of different spin times (1~60s) and speeds |

|

Liquid Injecting |

· One 20 mL syringe is included for liquid injection · Support rod and swing arm of injector are included for easy coating · The syringe holder height can be adjusted and rotated freely along the support rod |

|

Optional |

· You may choose Precision Electronic Single Channel Pipette: 20 - 200uL for more accurate coating · Using plasma cleaner to treat substrate surface before coating can improve film quality |

|

Product Dimensions |

13''(L) x 10''(W) x 7''(H) |

|

Net Weight |

30 lbs |

|

Compliance |

CE Certified |

|

|

· One year limited with lifetime support · Rusting and damage due to improper storage condition or maintenance are not covered by warranty |

|

Application Notes |

· In order to achieve optimal coating quality, please consider cleaning substrates by a plasma cleaner (click picture below for more details) prior to coating. This will significantly reduce the surface tension on the substrates. · You may place the compact spin coater into a glove box to operate in inert gas |

|

Warnings |

· Do not overflush the water bowl/base with any kinds of liquid. Excess liquid will leak into the motor shaft and cause damage. Please use fabric cloth to wipe out the residues remain in the bow/base. · If necessary, turn on the water outlet when flushing the water bowl/base to avoid liquid overflowing during the operation |

|

Shipping Dimensions |

20"(L) x 16"(W) x 18"(H) |

|

Shipping Weight |

38 lbs |

|

Item # |

Description |

Qty |

|

1 |

501 Desktop Spin Coater |

1 |

|

2 |

4" Dia. Spindle Plate (one installed and one included in package) |

2 |

|

3 |

Plastic Cover for operation safety |

1 |

|

4 |

20mL Syringe for dropping coating solvent on the plate |

1 |

|

5 |

Drain Hose for disposing of waste water |

1 |

|

6 |

Removable Double Side Tape for sticking substrate onto the spindle plate |

1 |

|

7 |

4" Dia. Soken Tape |

5 pcs |

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to production season and order quantity.

1. Which procedure to secure your Quality?

1.Order processing?

Customer Reviews total 0 items