North America 50.00%

Western Europe 20.00%

Eastern Europe 10.00%

Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

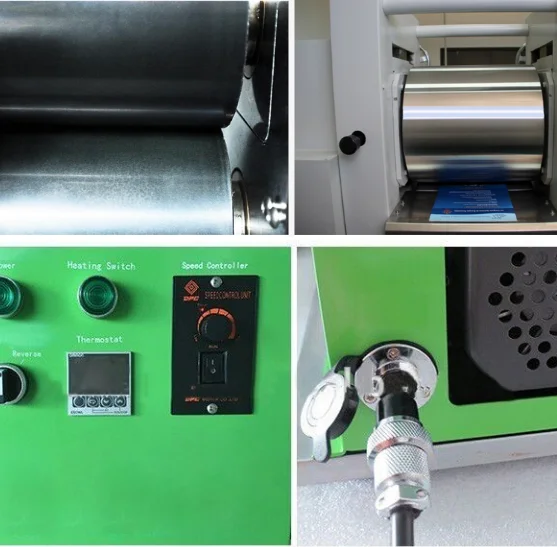

1. TMAX-JS is compact Hot Rolling Cylinder Press with max. working temperature of 150°C, which is designed for preparing battery electrode for both inside or outside glove-box. High torgue DC moter is Ar gas compatible. It serves well in the application such as increasing active material density of the electrode in Li-ion batteries research after coating. It has a pair of steel rollers with a heating capacity of 150°C max.

2. TMAX-JS is equipped with 24V DC motor for a safe operation under Ar gas environment.

3. Hot roller press machine is a compact hot rolling press machine mainly serves for pressing samples in the lab or other applications in the material research especially for increasing active material density of the electrode in Li-Ion batteries research after coating.

2 The hot roller press machine has 100mm to 300mm width steel rollers. Such a roller can be heated up to 150°C.

Specifications

| Model | JS100 | JS150 | JS200 | JS250 | JS300 |

| Roller Size | 96mm(Dia.) x 100mm(W) | 96mm(Dia.) x 150mm(W) | 96mm(Dia.) x 200mm(W) | 96mm(Dia.) x 250mm(W) | 96mm(Dia.) x 300mm(W) |

| Effective Cylinder Width | 96mm | ||||

| Product Thickness | 0~1.8 mm adjustable | ||||

| Dial Gauge Accuracy | 0.01mm | ||||

| Minimum Thickness | Depending on the electrode's material and thickness, typically: A 0.16mm thick electrode coated on copper can be pressed into a minimum thickness of 0.1 mm A 0.06mm thick electrode coated on copper can be pressed into a minimum thickness of 0.04 mm A 0.33mm thick silver/gold can be pressed into a minimum thickness of 0.03 mm | ||||

| Heating Temperature | 150°C maximum Recommended Heating Rate: 1.3°C/minute Power of Heating Element: 800W Temperature Control : Precision temperature controller with +/-1°C Accuracy | ||||

| Working Voltage | 110V - 240V AC, 50/60Hz, automatic switch for worldwide use | ||||

| Roller | 1. Roller diameter tolerance: 0.004mm | ||||

| Roller Surface Hardness | 62 HRC Never roll materials with hardness > 50HRC | ||||

| Compliance | CE Certificate | ||||

| Warranty | One Year limited warranty with lifetime support | ||||

| Warnings | 1. Do not touch the surface of the rolling part of the machine when the rollers are heated up or running. 2. Never roll materials with hardness > 50HRC 3. Heating the cylinder beyond 100ºC results in roller deformation and causes inaccurate, thicker-than-usual rolling yield. 4. In order to prolong the lifespan of the roller bearings, regular lubrication is recommended. 5. Clean roller surface for each rolling and Use acetone to clean and lubricate when not in use to avoid corrosion. 6. This rolling machine can be used under Ar gas. | ||||

Product Images

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

3-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.

Customer Reviews total 0 items