North America 50.00%

Western Europe 20.00%

Eastern Europe 10.00%

Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

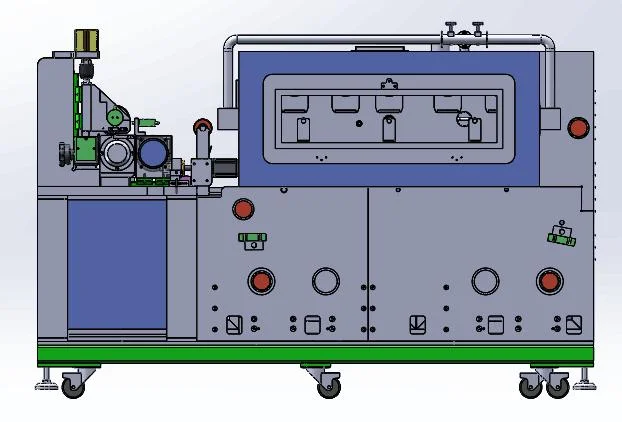

This coater is a three roll transfer coating equipment, which can be used for continuous and intermittent coating, and is convenient for surface coating of various substrates. Especially used in the lithium-ion battery industry, the device is designed to facilitate researchers to use, and meet the requirements of coating accuracy and consistency, which is no different from the production requirements. It has excellent drying effect, and is an ideal choice for lithium-ion batteries, supercapacitors, nickel batteries and other secondary batteries.

Features

*It can switch freely to realize continuous and intermittent coating;

*Base material tension control, stable belt running, and deviation correction device;

*Hot air oven, upper and lower double side blowing, drying effect is high quality;

*Three roll transfer coating with wide coating window;

*Comma scraper metering, with precision adjustment mechanism, to obtain high coating precision;

*PLC control, touch screen operation, easy to use;

*Optional solvent recovery and treatment device;

Technical Parameter

|

No. |

Item |

Spec |

|

1. |

Fit system |

Coating process for positive and negative plates of ternary, lithium iron phosphate, lithium cobalt oxide, lithium manganese oxide, graphite, silicon carbon and other systems |

|

2. |

Coating method |

Continuous coating and intermittent coating |

|

3. |

Number of oven sections |

One 1 meter oven(can be customized) |

|

4. |

Coating speed |

0~0.5m/min |

|

5. |

Operating substrate thickness |

Aluminum foil: 8~30um Copper foil: 8~30um |

|

6. |

Design width of roll surface |

330 mm |

|

7. |

Effective coating width |

Within 280mm(can be customized) |

|

8. |

Coating roller |

φ120mm |

|

9. |

Scraper roller |

φ80mm |

|

10. |

Coating accuracy |

±3um |

|

11. |

Weight accuracy of double-sided coating (mg / cm2) |

Coating center value±1.0% |

|

12. |

Suitable for slurry viscosity |

2000~12000 (mPas) |

|

13. |

Single side coating dry thickness range |

20-200μm |

|

14. |

Solvent properties

|

Oily solvent NMP(s.g=1.033,b.p=204℃) |

|

15. |

Water-based H2O/NMP(s.g=1.000,b.p=100℃) |

|

|

16. |

Suitable for solid content range |

20~85% |

|

17. |

Coating size accuracy (mm) |

L≤±1,W≤±0.5 |

|

18. |

Front and back alignment accuracy (mm) |

L≤±1,W≤±0.5 |

Product Images

Related recommendations

|

Coater type |

Description |

Machine images |

|

Doctor Blade |

Cost effective solution for 8~200 micron thick coatings (Continuous mode only) |

|

|

Reverse Comma Blade (Transfer Coating) |

Cost effective solution for 30~200 micron thick coatings (Both continuous & intermittence mode) |

|

|

Slot Die |

Suitable for precision coatings as thin as 1 micron while providing a wide coverage for thicker coatings upto 200 microns |

|

|

Micro-Gravure |

Perfectly suitable for precise thin coatings from 1~3 microns (dry film thickness), suitable for separator coating |

|

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.

Customer Reviews total 0 items