North America 20.00%

South America 15.00%

Eastern Europe 15.00%

Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

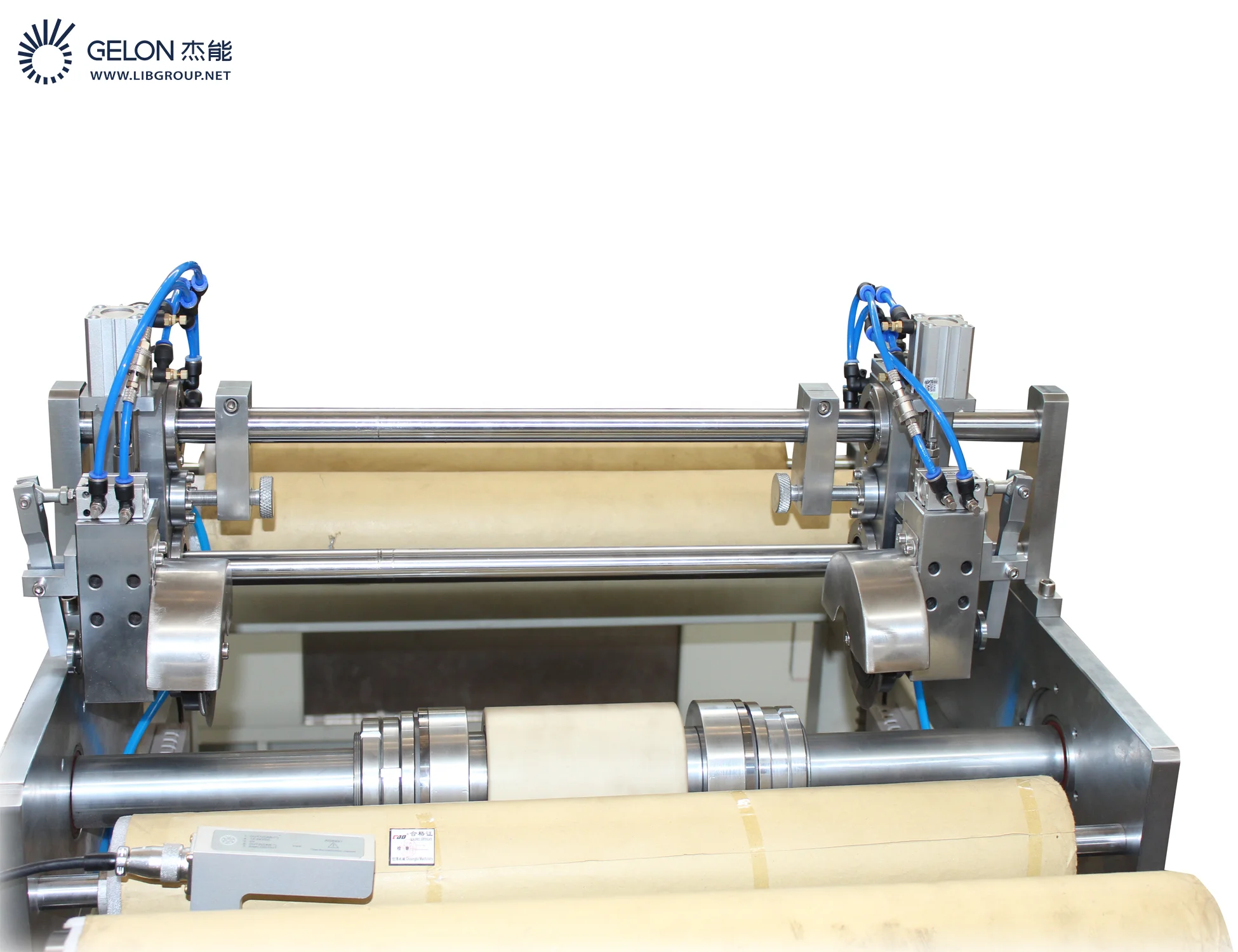

Rolling machine is the main equipment in continuous rolling production line. It is composed of rigid frame, roll pair, motor reducer, gas-liquid supercharging system, clearance adjustment system, electrical control system, feed plate and roller surface cleaning mechanism.

The main function is made electrode under the rolling,to bring the electrode to a proper density. And according to the coating thickness to achieve the electrode thickness requirements. This equipment adopts the lead screw wedge iron gap adjustment structure to adjust the roller gap, and the linear speed is adjusted by frequency converter to realize stepless speed regulatio

Equipment technology (equipment configuration and parameters):

Rolling specification:∮300X350mm(Roll surface diameter × roll surface width)

Electrode or foil type: battery electrode

Coating uniformity: ±0.003mm(User guarantee)

Electrode thickness uniformity after rolling≤±0.003mm Under the premise that the user guarantees the uniformity of the coating,Pressure roll layout two roll horizontal arrangement

Machine appearance:Computer grey, red

Protective devices with guard colors

Main function: The electrode can reach a certain thickness under the rolling of the roll.

Structure: Two rollers up and down horizontal layout, "mouth" mold casting archway

Integral size(L×W×H): about 1700mm L×600mm W ×1200mm H

Bearing: Special bearing for rolling mill

Lubricating: 3# lithium-base lipids

Rolling: Spec ∮300X350mm(Roll surface diameter * roll surface width)

Effective use width: 300mm

9Cr3Mo series high alloy cold roll steel

Surface hardness: Above HRC66

Quenching depth: 12~15mm

Roll diameter slip:≤±0.003mm

Roll surface roughness: Ra≤0.4

Roller gap adjustment: wire rod drive intermediate wedge iron adjustment

Roll gap adjustment range: 0~3.0mm

Roller press drive: Cycloidal pin wheel reducer

Pressure mode: Pneumatic hydraulic pump

Specification of hydraulic cylinder: cylinder diameter:φ125mm Route:10mm

Maximum working pressure: 50MPa

Mainframe weight: about 1T

Main motor power: 0.75KW(220V 50Hz) 700N.m

Heating function:The heating temperature is up to 80 °C- 120 ℃.

We also can supply others:

1.)full set of lithium battery materials,including :

LiMn2O4,LTO,LiNiMnCoO2(NMC),LiCoO2,Graphite(MCMB)and other cathode&anode battery materials;Alumimun foil,copper foils,battery separator,etc.

2.)full set of lithium battery equipments,for example:

mixing machine --coating machine--oven--rolling machine--welding machine--slitting / cutiing machine --winding machine--sealed machine,etc.

3)full set of lithium battery technology.

we can design the laboratory and production line,according to customer's request.

Name: hydraulic calendaring machine

Brand: GELON

Original: China

calendaring machine--Unreeling(optional)--Reeling(optional)--heating(optional)

Name: hydraulic calendaring machine

Brand: GELON

Original: CHINA

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

91.8% Response Rate

91.8% Response Rate

91.8% Response Rate

Customer Reviews total 0 items