Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

Product Details

low cost SMT PCB assembly machine lead-free reflow oven for led light making machine

Introduction:

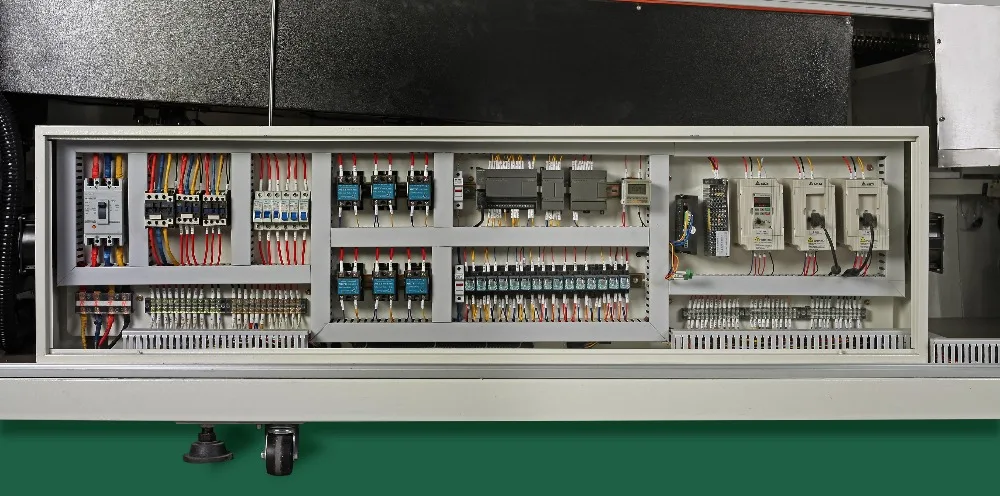

1. The brand computer and Siemens PLC intelligent control system, high precision temperature control is ± 1-2 ℃ (if the computer crash accident, it can realize off-line work, do not affect production) and to ensure that the control system is stable and reliable;

2. Windows XP operating interface with powerful and simple operation.

3.In order to ensure safety and reliability, the cylinder body can be lift up automatically.

4. Device is equipped with mesh belt, transport smoothly, no shaking and no deformation, which ensure smooth PCB transport. Synchronous guide transmission mechanism and automatic SMT machine online connection ensure that guide adjustable wide precision and high service life.

5. Automatic control lubrication system and automatic lubrication transmission chain.

6.All heating zone control by computer PID(upper temperature zone and lower temperature zone implementation independent temperature control, that means it can divide temperature area heat, in order to reduce starting power)

7. Net/chain transmission by computer to carry out the whole closed loop control, which can meet different kinds of PCB production at the same time.

8. With fault sound and light alarm function.

9. With leakage protector, ensure that the operating personnel and control system security.

10.The built-in UPS and automatic delay shutdown system guarantee return welder in power or overheat do not damaged PCB and the machine.

11. The German ERSA world leading microcirculation heating mode, and the upper and lower independent air microcirculation system, temperature uniformity and thermal compensation high efficiency, high efficient supercharged accelerated air duct, greatly improve the circulating hot air flow, heat up temperature quickly (about twenty minutes), thermal compensation for high efficiency, high temperature welding and curing;

12. The upper and lower every temperature zone with independent temperature inductive sensor, real-time monitoring and compensation every temperature zone balance;

13. Have password administration of the operating system, to prevent the irrelevant personnel changes to the process parameters, operation records management traceability process parameters change process, improve the management convenient. For storing user existing temperature speed setting and Settings of the temperature curve, and can be used for all data and curve printing;

14. Integrated control window, the computer switch, test curve, print curve and data transmission are easily operation, humanized design. Equipped with three-channel temperature curve online testing system, may at any time to check welding objects by the actual temperature curve (without the other match temperature curve tester);

15. From international technology quick cooling system, use a magnifying glass type efficient rapid cooling, cooling speed can reach 3.5 ~ 6 ℃/ SEC, management is very convenient; The outer forced cooling device, ensure that spot crystal effect (Option selected items, the standard configuration for forced natural air cooling).

Specification:

Model | Jaguar F12 | ||

Heating System | Number of heating zones | Up 12/ bottom 12 | |

Number of cooling zones | 2(up 1, bottom 1) | ||

Length of heating zones | 4500mm | ||

Heating mode | Hot air | ||

Cooling Mode | Forced air cooling | ||

Exhaust Volume | 10m³/min * 2 exhausts | ||

Conveyor System | Max. Width of PCB | 400mm | |

Mesh belt width | 450mm | ||

Transmission Direction | L→R(option: R→L) | ||

Transmission Net Height | 900±20mm | ||

Transmission type | Mesh and chain | ||

Range of rail width | 50-400mm | ||

Conveyor speed | 0-2000mm/min | ||

Auto/manual Lubrication | Standard | ||

Fixed rail side | Front rail fixed(option: rear rail fixed) | ||

Components high | Top and bottom 25mm | ||

Control system | Power supply | 5 line 3 phase 380V 50/60HZ | |

Total power | 68KW | ||

Starting power | 60KW | ||

Normal power consumption | 12KW | ||

Warming time | 20 mins | ||

Temp. setting range | From room temp. To 300℃ | ||

Temp. control method | PID close loop control & SSR driving | ||

Temp. control precision | ±1℃ | ||

Temp. deviation on PCB | ±2℃ | ||

Data storage | Process Data and status storage(80GB) | ||

Nozzle plate | Aluminum Alloy Plate | ||

Abnormal Alarm | Abnormal temperature (extra-high/extra-low temperature) | ||

Board dropped alarm | Tower light: Yellow-warming,Green-normal, Red-abnormal | ||

General | Dimension(L*W*H) | 6100*1320*1490mm | |

Weight | 2600kg | ||

Color | Computer gray | ||

Keywords:

reflow oven,smd soldering,soldering machine,reflow soldering, reflow soldering oven,smt reflow oven,reflow machine,smd reflow oven,pcb oven,soldering oven,smd soldering machine,pcb reflow oven,cheap reflow oven,t962 reflow oven,convection reflow oven, reflow oven price,small reflow oven,reflow soldering machine,reflow oven kit,smd oven,smt oven,smd soldering oven,smt reflow,low cost reflow oven,smd reflow,surface mount soldering,lead free reflow oven, hot air reflow, infrared reflow, convection reflow, reflow station, reflow soldering oven price,infrared oven,smt reflow oven manufacturers, hot air reflow oven

Shenzhen JAGUAR Automation Equipment Co., Ltd. : To provide professional SMT automatic production line solution, The company specializes in SMT chip mounter(New Samsung: SM482, SM481, SM471, Decan-F2 etc); YAMAHA SMT machine (YAMAHA Chip shooter); JUKI chip mounter, Siemens SMT machine, Panasonic SMT Chip mounter, FUJI second-hand SMT machine. We are also sell printing machine, Point glue machine,Reflow soldering, Wave soldering machine, Automatic plug-in machines, stencil printer, Reflow oven, flow welding, AOI, X-ray, LED automatic die bonder etc.

Shenzhen Jaguar Automation Equipment Co., Ltd (referred to as "Jaguar") is a High-speed developing enterprise of High Precision Automatic lead-free Equipment such as reflow oven and wave soldering machine manufacturer, which specializes in lead free machine research and development for years.

As one of the well-known lead-free electronics equipment manufacturers in China, JAGUAR was founded in 2009 and headquartered in Shenzhen.

so, what we can do for you and what kind of services we can offer?

1. we can provide full SMT solution.

2. we can provide you with top technical support.

3. we have enrich experience on SMT factory set up.

4.we can provide the best professional tech service.

5.we can help you to deal with all the trouble about SMT.

6.we are committed to provide the best solution to our clients.

Services and products:

Our company is professional in manufacturing wave soldering machine and reflow oven,besides both two kinds of products, we also engaged in offering SMT conveyor, pick and place machine, LED equipments, PCB loader and unloader, solder paste and other SMT machines.

Before buying the product, we will be a comprehensive analysis of the views and requirements and recommend it to the actual needs of customers with the most suitable products and let customers know that the performance characteristics of the selected product referred to in accordance with customers.

In purchasing the products, we promise to allow customers to clearly know the completion of the product. In strict accordance with the relevant provisions of the contract terms of production, delivery, to ensure product intact and in place within the stipulated time to customer requirements.

Product during the warranty period, under normal storage, maintenance, use, if quality problems, responsible for the free repair or replacement, and provide the relevant maintenance knowledge; as a result of improper use or damage caused by the product does not work normally, the Company provides paid service. Product warranty period is not, it will provide a paid service.

The company promises:

We highly value your feedback on the quality of information, all the information will be given to the quality of feedback responses;

In accordance with the contract requirements for the installation, commissioning and training of technical personnel for the buyer sold the equipment.

During the warranty period, except for man-made damage and force majeure factors, the device itself quality problems, maintenance service commitment.

I provide long-term technical support, vendor outside the warranty period if you need on-site service, only pay the cost (within China).

Our company has adequate supply of consumable buyer if requested to order spare parts, our company can provide timely.

FAQ:

1) This is the first time I use this kind of machine, is it easy to operate?

There is english manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

5)Why choose us ?

A. Gold supplier on Alibaba !

B. Trade assurance to US$54,000 !

C. Best price & Best shipping & Best service !

Contact Info:

Paul

Mob &Wechat &Skype: +8615889682100

Tel:+86-755-23316315 Fax:+86-755-29497125

Shenzhen Jaguar Automation Equipment Co.,Ltd.

Add:Building A07,hongtian jinyuan industrial zone,hongtian road, xinqiao street,shenzhen,China

Web: www.jaguar-ele.net

Share

Share

Customer Reviews total 0 items