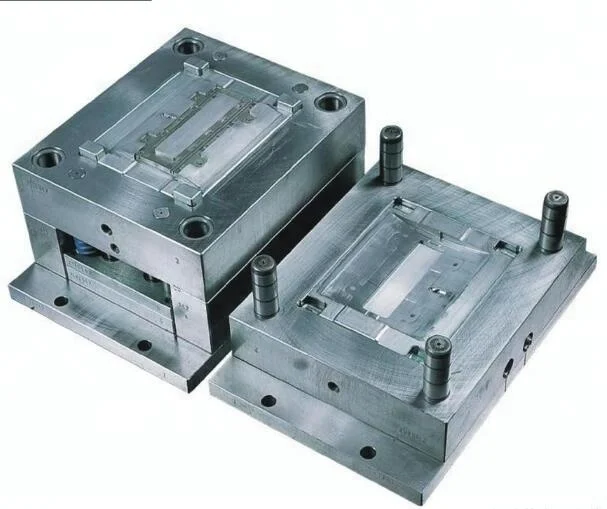

1,Q:How many moulds could you make every month?

A:60-80 sets.

2,Q:How about the largest mould you ever made?

A:15 ton. The size is 1.8m * 1.5m.

3,Q:How about the tolerance?

A:Mould tolerance 0.005mm, Product tolerance 0.01mm.

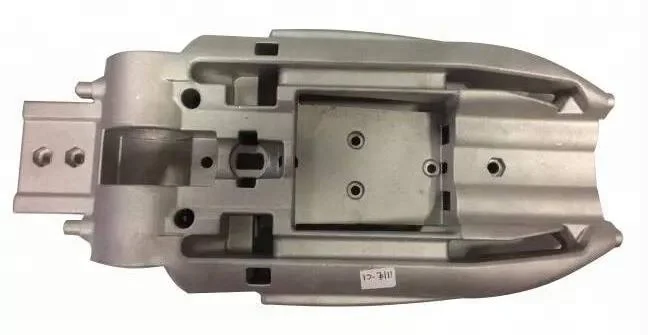

4,Q:What is percentage of automotive moulds you made? What's the brand?

A:About 40%. Brand: Volvo, TOYOTA,Land Rover.

5,Q:Can you make precision mould ?

A:Yes. We have made precision moulds such as moulds for medical devices.

6,Q:How about the steel you usually use?

A:We only use raw materials with good quality like P20, P20H, 718H, NAK80,1.2311,1.2378, 1.2344, 1.2767, H13,8407, 420SS, S136, S-7. They are all from famous suppliers, such as LKM, ASSAB, THYSSEN, etc. Steel quality certificate and heat-treatment certificate will be provided along with the tools while delivery.

7,Q:What about the standard components you use?

A:We use standard components from LKM,, HASCO, DME, etc.

8,Q:What do you need for quotation? And what about the format?

A:2D & 3D part files are preferred. Or specific sample with detailed description and mould specification. We use PROE, AUTOCAD, Acorbat Reader, Solidworks, UG and etc. All format related are acceptable.

9,Q:How long do you need for quotation?

A:Exact quotation will be available within 2 working days once we get sufficient information from customer.

10,Q:What is your turnround time for die casting mould building?

A:Usually 4-8 weeks. It also depends on mould size and structure complexity.

Share

Share

Customer Reviews total 0 items