North America 50.00%

Western Europe 20.00%

Eastern Europe 10.00%

Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

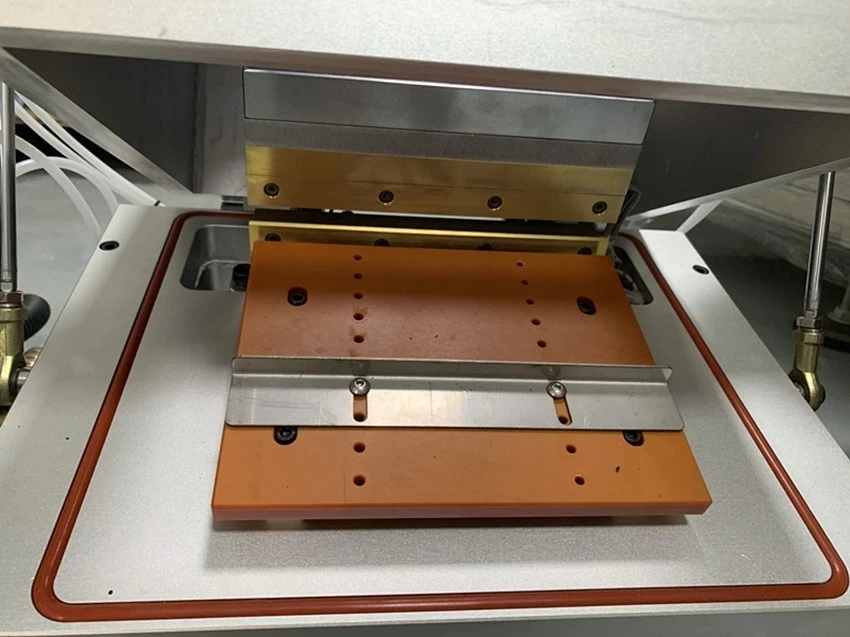

Pouch Cell Vacuum Crimping Crimper Machine For Lithium Battery Laboratory Research Scale

Features

This equipment is mainly suitable for vacuum hot sealing of pouch cell after electrolyte filling and standing; the machine can automatically complete vacuum thermal sealing of aluminum laminated film by precisely controlling the main vacuum pumping box and pneumatic heat sealing components.

*Simple operation, beautiful appearance, small volume and light weight.

Specification

|

Chamber |

The chamber is made of aluminum alloy, which is corrosion resistant and has a firm structure; |

|

Vacuum degree |

The vacuum degree can be adjusted up to -95Kpa (the buyer shall provide the vacuum pump); |

|

Head temperature |

Room temperature~250℃, temperature adjustable; |

|

Temperature control accuracy |

±2℃; |

|

Heat sealing pressure |

0~7Kg/cm2 adjustable; |

|

Heat sealing time |

0~99 seconds adjustable; |

|

Edge sealing width |

5±0.4mm (can be customized) |

|

Maximum edge sealing length |

200mm (can be customized, such as 300/400/500mm sealing length) |

|

Seal thickness range |

60~300um |

|

Seal thickness accuracy (mm) |

Sealing thickness difference between any two points<15um |

|

Air consumption |

About 0.2L compressed gas per seal once. |

|

Working speed of air compressor |

≥180 times/h |

|

power |

Using 300w heating tube, the power consumption when heating is about 0.6KW. |

|

Power Supply |

220V/50Hz; |

|

Compressed air source |

0.5~0.8Mpa; When used in the glove box, the cylinder power source must use the same working gas used in the glove box; |

|

Working chamber |

470mm*485mm*435mm; |

|

Control box |

420mm*325mm*225mm |

|

Equipment weight |

About 50Kg |

Detailed Images

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.

Customer Reviews total 0 items