Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

Product Details

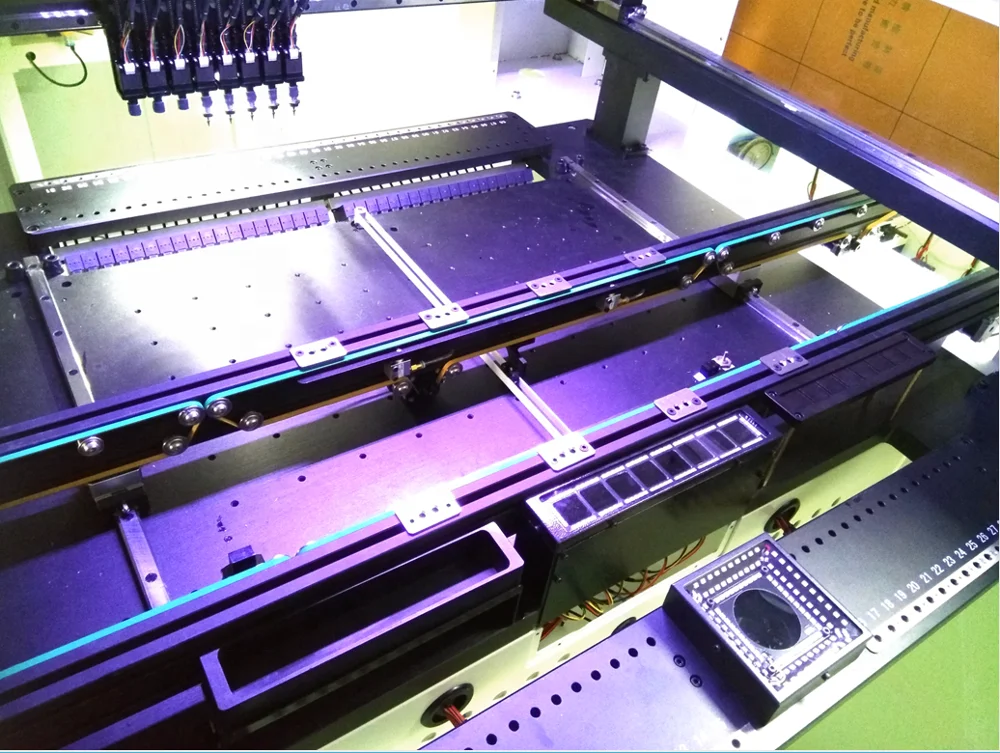

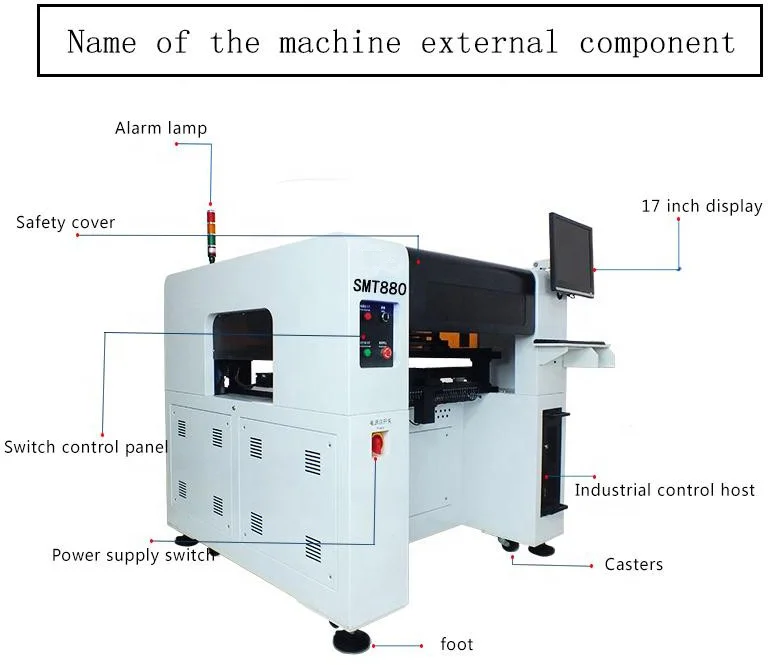

smt New Generation SMD Mounting Equipment SMT Chip Mounter Machine 12000-15000cph

FEATURES:

Suit for variety of SMD LED components, and high-power LED/IC

Using imported high precision ball screw, motor, electromagnetic valve, cable, etc., effectively improve the placement accuracy, stability and service life of machines.

1: Why choose us?

First of all, quick respond, save your time, time equals money, so we save money for you. see, you are already saving money, even you contact us.

2: Should I worry about the quality?

My dear friend, our company joined the Alibaba Trade Assuracne, if you got defective goods, we got Alibaba on our tail, that's not what we want, and that's not how we do business.

3: How's about the transportation?

If you ask this question, I guess that you missed the picture above. DHL, FedEx, UPS, TNT, and so on, tell us which one you don't like, we will keep that in mind.

4: How do I pay?

My friend, there are many ways. T/T(we prefer this one), Western Union, PayPal, choose your favorite one.

5: How's after-sale service?

If, unfortunatly, you received defective goods, ah oh, this is an unpleasant situation, no one want it. But don't you worry about it, problems come out, we will be there to make it disappear. Believe us, it will be a happy ending.

6: How to operate the equipment?

My friend, don't worry about it, we have made vedio for your, it will show you how to do it step by step.

Contact information:

Ms. Joy Rong

WhatsApp/wechat: +8618779975930

Email: joyrongzhuomao AT outlook.com

Facebook:@lCDbga.repairmachine

Youtube: https://www.youtube.com/channel/UCVRPUzG3NtNR9kdSwSfJsBA

facebook: https://www.facebook.com/lcdbga.repairmachine/

China manufacturer supplier bga rework soldering station

Contact Information:

Ms. Joy Rong

www.seamarkxray.com

WhatsApp/wechat: +8618779975930

Email: info AT seamarkxray.com

Facebook:@lCDbga.repairmachine

Youtube: https://www.youtube.com/channel/UCVRPUzG3NtNR9kdSwSfJsBA

facebook: https://www.facebook.com/lcdbga.repairmachine/

China industrial x ray SMT Line inspection machine for Motherboard BGA X-Ray Inspection Equipment

MOQ: 1 Piece

Payment: TT/paypal

Express: DHL/Fedex

EX Work: Shenzhen,China

Delivery Date: 3-5 Working days after payment arrived

Manufacturer Warranty: 1-Year ,if any problem,we will provide tech support and parts exchange.

Share

Share

Customer Reviews total 0 items