North America 20.00%

Western Europe 20.00%

South Asia 20.00%

Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

Ultrasonic Wire To Wire Splice Machine

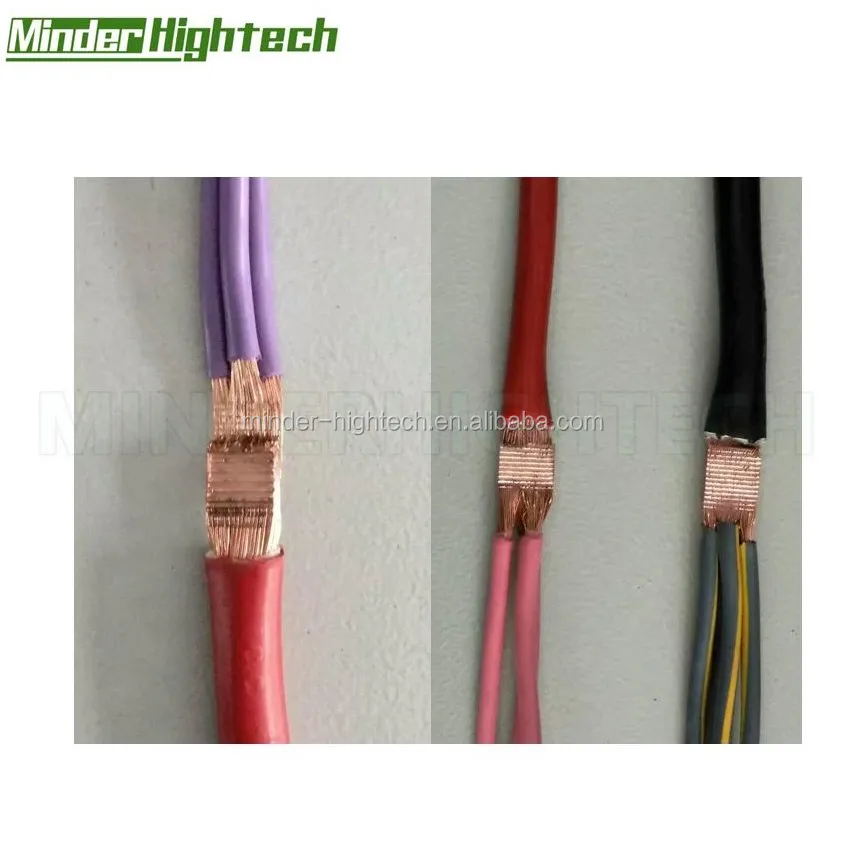

Ultrasonic Metal Welding is the future-oriented method for wire and terminal applications. The welding machine is a new industrial ultrasonic wire splice solution. It welds stranded, braided and magnet wires to create a wire splice, wire crimp or a battery cable splice. The connections it produces are used in the automotive, aircraft, computer and consumer electronics industries, as well as other process control and industrial instrument applications. It is most commonly used in the production of wire harnesses.

Compared with crimping or resistance welding, this process offers numerous advantages. Besides the excellent electrical properties of the joint and the extremely low energy consumption, this method is particularly characterized by comprehensive process control and process data management.

Ultrasonic Welding Principle:

l Ultrasonic metal welding machine use ultrasonic frequency vibration principle to change ultrasonic vibration energy into friction energy and transfer to the metal surface to be welded ,while the friction produces heat under the pressure, the metal structure of molecules fully activation of the fusion between the molecular layer of the formation of the new equipment.

Features

l Automatic splice width adjustment from 0.5 to 40 mm (depending upon power level)

l Microcomputer control, electronic tuning frequency.

l Power adjustable, operate simple, and run stable and reliable.

l LED display keeps the machine visible in operation and regulation.

l Imported components, good performance in energy output.

l Overcurrent protection and soft start can keep the machine safe.

l Easy installation and operation.

l Not only similar metal, but also dissimilar all can welding together. it can weld metal slice or sleave to thick metal. Usually used for transister or IC's leads welding.

Advantages

l High-quality ultrasonic transducer, strong power, good stability.

l Good conductivity and resistivity very low or almost near to zero.

l Oxidation or plating metal can be welded.

l Short weld time, no need additional flux, gas, solder.

l No welding sparks, environment protection and safety.

l Without the need for frequent replacement of amplifier due to stepless adjustment of the amplitude.

l Low energy consumption, high efficiency, no distortion, no pollution, welding firm, and convenient operation.

l Welding material does not melt non-fragile metal properties.

l Pairs of welding metal surfaces that require low, oxidation or plating can be welded.

Specification

|

Frequency |

20 kHz Nominal |

|

Power |

Available in: 2000 W ~5000W |

|

Welding Area |

Fully automatic splice set-up from 0.5 mm² to 80 mm² and beyond |

|

Source Voltage |

AC 110/220±10% V 50/60±10% Hz |

|

Generator Type |

Digital automatic frequency tracking, generator can be adjusted the output amplitude from 5% to 100% |

|

Pneumatic Pressure |

0.3-0.6Mpa |

|

Size |

Controller: 420mm(L) * 380mm(W) *200mm(H) Welder: 510mm(L) *280mm(W) *210mm(H) |

|

Weight |

Welder : 35~50kg, Controller : 10kg |

|

Warranty |

One year warranty with lifetime support |

Application area

l Multi-layer positive and negative electrode welding for dynamic power battery

welding material does not melt, non-fragile metal properties.

l Li-ion battery and polymer battery: Copper foil welds nickel sheet; Aluminum foil welds aluminum sheet; Aluminum foil welds Nickle sheet.

l Auto splice welding, Formation of electric wire end, Welding for electric wires; Multiple electric wires bond welding.

l Electric wire and cable welding, terminal , connector , electric parts welding .

l Solar panel battery, flat solar plate , copper and aluminum plate joints.

l Solenoid switch, fuseless switch: big currency joint point welding and dissimilar metal welding.

l Refrigerator and air conditioner copper tube sealing. Vacuum parts of copper tube and aluminum tube sealing.

In addition, advances in metals technology are producing thinner and lighter metal foils and wire for use in sensitive electronics and other products. Ultrasonic metal welding can satisfy the clean and delicate requirements of these applications, whereas traditional welding methods may be much too destructive.

Ultrasonic welding also meets the reliability demands of larger, heavy-duty applications such as charging systems for electric vehicles, wind power towers and solar energy systems.

Please Click on the Picture to See More Models

Please Click on the Picture to See More Models

1 Standard exported package: Internal anti-collision protection, external export wooden box packaging.

2 Shipping by Fedex, by air, by sea according to customers' requirements to find the most suitable way,

3 Responsible for the damage during the shipping process will change the damage part for you for free.

4 Supply with the suitable voltage input and source plug according to your country requirements.

1. Help customer analyze product project and provide welding solution.

2. Freely sample welding test.

3. Provide professional welding solution.

4. Skilled jig design services.

5. Provide shipping/delivery information checking service.

6. One year guarantee, all life maintain promise.

7. 24 hours feedback speed by email of others.

| F.A.Q |

Q: Can I have my LOGO on my products?

A: Yes, We can offer LOGO silk-screen, grave. LOGO fee could be free while order quantity reach requirement.

Q: What is the bulk order delivery time?

A: Order lead time will be 5-10 working days

Q: How long is your warranty?

A: Lasts for 12 months.

Q: How could I make the payment?

A: Paypal, T/T, Western Union and Escow are the most popular methods.

Q: How about the package?

A: Foam and wooden case to protect products.

Q: How about the delivery method?

A: Normally we will take express such as DHL, Fedex, UPS and TNT for sample orders.For bulk order, will take air flights or Sea shipment.

Customer Reviews total 0 items