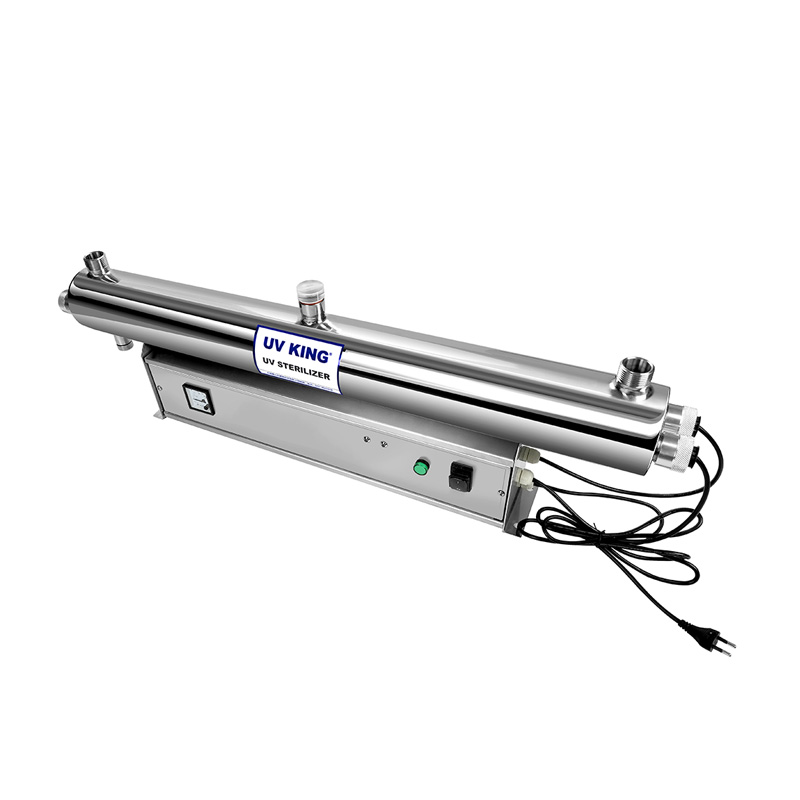

Application of large stainless steel sterilizer

The application of ultraviolet radiation in the disinfection of drinking water has been well promoted and developed in Europe. Hundreds of public drinking water suppliers in European developed countries have used ultraviolet disinfection technology. Replacing traditional chlorine swimming water with ultraviolet disinfection would be great news for swimmers who do not like the smell of chlorine

The ultraviolet sterilization technology is a supplement to the traditional water treatment methods. It reduces the amount of chlorine at least 50 %, greatly reducing the impact of chlorine on water quality, but achieves the same disinfection effect. Large stainless steel sterilizer can also be used in the aquarium. Ultraviolet sterilization effectively inhibits the regeneration of halobios faeces and bacteria in the water.

It is a common understanding of mankind that human health is seriously threatened by the deteriorating water environment. Unsterilized water contains a large number of microorganisms and bacteria. People are vulnerable to various diseases after drinking it, especially young children the elderly with relatively weak immune systems. Integrated stainless steel sterilizer has been widely used in the domestic drinking water pipeline and drinking water dispenser industry. 304 stainless steel tubes effectively ensure the hygiene of water quality. UV lamps can strongly and effectively inhibit the growth of various bacteria, greatly reducing the possibility of bacterial regeneration in water quality.

One-piece stainless steel sterilizer is also used in some high-level water filtration systems for ornamental fish tanks. The use of 304 stainless steel material and the housing inner wall polishing technology make the liquid that flowing through have no incrustation on the inner wall of the lamp tube. In addition, the high efficiency irradiation of UV ultraviolet lamps prevents various valuable ornamental fish threatened by bacteria that breed in the water body any longer. And the balanced environment between organisms and water bodies greatly prolongs the life of fish.

| MODEL | RATE FLOW | POWER | MNPT THREAD | SHELL SIZE |

|

|

/

| /

| /

| /

| /

| L | D | H | /

| /

|

/

| m³/h | GPM | W | in | mm | mm | mm | /

| /

|

| UV-D08 | 0.20 | 0.8 | 8W | 1/4" | 220 | 38 | 55 | /

| /

|

| UV-S01 | 0.30 | 1 | 10W | 1/4" | 270 | 51 | 71 | /

| /

|

| UV-S02 | 0.45 | 2 | 14W | 1/2" | 350 | 63 | 88 | /

| /

|

| UV-S03 | 0.68 | 3 | 17W | 1/2" | 360 | 63 | 88 | /

| /

|

| UV-S06 | 1.36 | 6 | 21W | 3/4" | 490 | 63 | 88 | /

| /

|

| UV-S08 | 1.81 | 8 | 28W | 3/4" | 600 | 63 | 88 | /

| /

|

| UV-S12 | 2.71 | 12 | 40W | 3/4" | 906 | 63 | 88 | /

| /

|

|

| MODEL | RATE FLOW | POWER | QUANTITY OF LAMP | MNPT THREAD OR FLANGE | SHELL SIZE |

/

| /

| /

| Total power | Number | screw thread flange | Long | Wide | High |

/

| M³/h | GPM | W | /

| /

| /

| mm | mm | mm |

| UV-5.5T40 | 5.5 | 24 | 80 | 2 | 1 1/4" | DN32 | 906 | 102 | 212 |

| UV-8T40 | 8.0 | 35 | 120 | 3 | 1 1/2" | DN40 | 906 | 159 | 360 |

| UV-12T40 | 12 | 53 | 160 | 4 | 2" | DN50 | 906 | 159 | 360 |

| UV-15T40 | 15 | 66 | 200 | 5 | 2 1/2" | DN65 | 906 | 219 | 420 |

| UV-12T80 | 12 | 53 | 160 | 2 | 2" | DN50 | 906 | 102 | 212 |

| UV-20T80 | 20 | 88 | 240 | 3 | 2 1/2" | DN65 | 906 | 159 | 360 |

| UV-25T80 | 25 | 110 | 320 | 4 | 2 1/2" | DN65 | 906 | 159 | 360 |

| UV-15T120 | 15 | 66 | 240 | 2 | 2 1/2" | DN65 | 1220 | 102 | 270 |

| UV-25T120 | 25 | 110 | 360 | 3 | 3" | DN80 | 1220 | 159 | 360 |

| UV-45T120 | 45 | 198 | 600 | 5 | 3" | DN80 | 1220 | 219 | 420 |

| UV-25T150 | 25 | 110 | 300 | 2 | 3" | DN80 | 1625 | 102 | 270 |

| UV-35T150 | 35 | 155 | 450 | 3 | 3" | DN80 | 1625 | 159 | 360 |

| UV-50T150 | 50 | 220 | 600 | 4 | 4" | DN100 | 1625 | 159 | 360 |

| UV-60T150 | 60 | 260 | 750 | 5 | 4" | DN100 | 1625 | 219 | 420 |

| UV-80T150 | 80 | 352 | 900 | 6 | 4" | DN100 | 1625 | 219 | 420 |

| UV-100T150 | 100 | 440 | 1050 | 7 | 4" | DN100 | 1625 | 270 | 450 |

| UV-125T150 | 125 | 550 | 1350 | 9 | 6" | DN150 | 1625 | 273 | 480 |

| UV-150T150 | 150 | 660 | 1650 | 11 | 6" | DN150 | 1625 | 323 | 530 |

part.1

Series of large production are large flow sterilizers with multiple lamps.

part.2

The standard layout of electric cabinet is : power supply 120/230VAC, running indicator light, audible-visual alarm light(accumulated timer and light-density detection device are optional), ballast with CE, Rohs, UL certification.

part.3

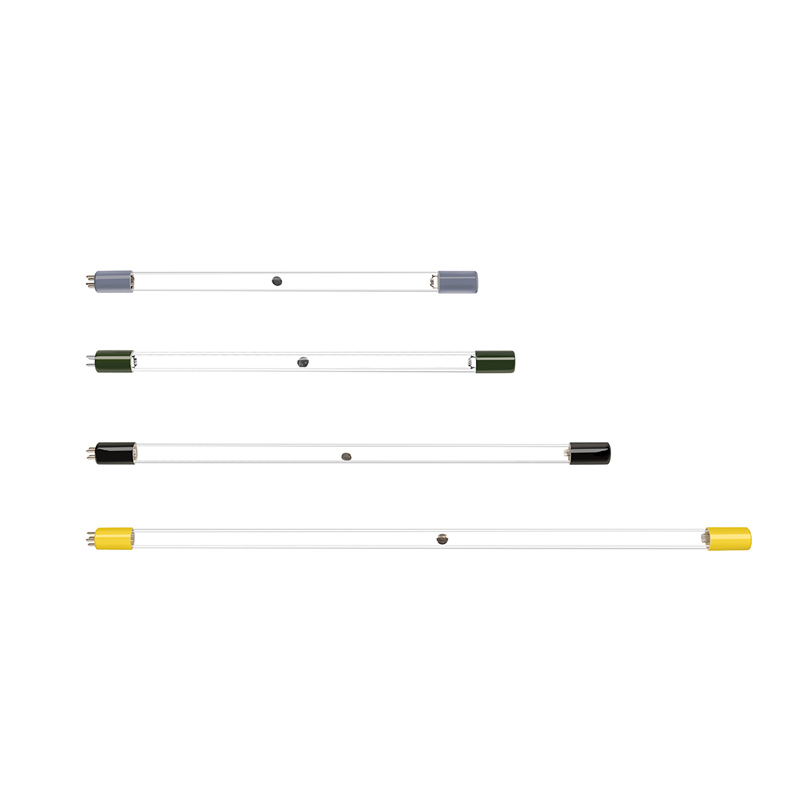

The useful life of sterilization lamp is longer.

part.4

Crust of the sterilizer is made of 304 stainless steel(316L, PVC-U material are optional) and it has a pressure resistance of 0.7 Mpa.

part.5

Crust of the sterilizer used the mechanical polishing technique (electrolytic polishing is optional).

Share

Share

Customer Reviews total 0 items