Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

Product Details

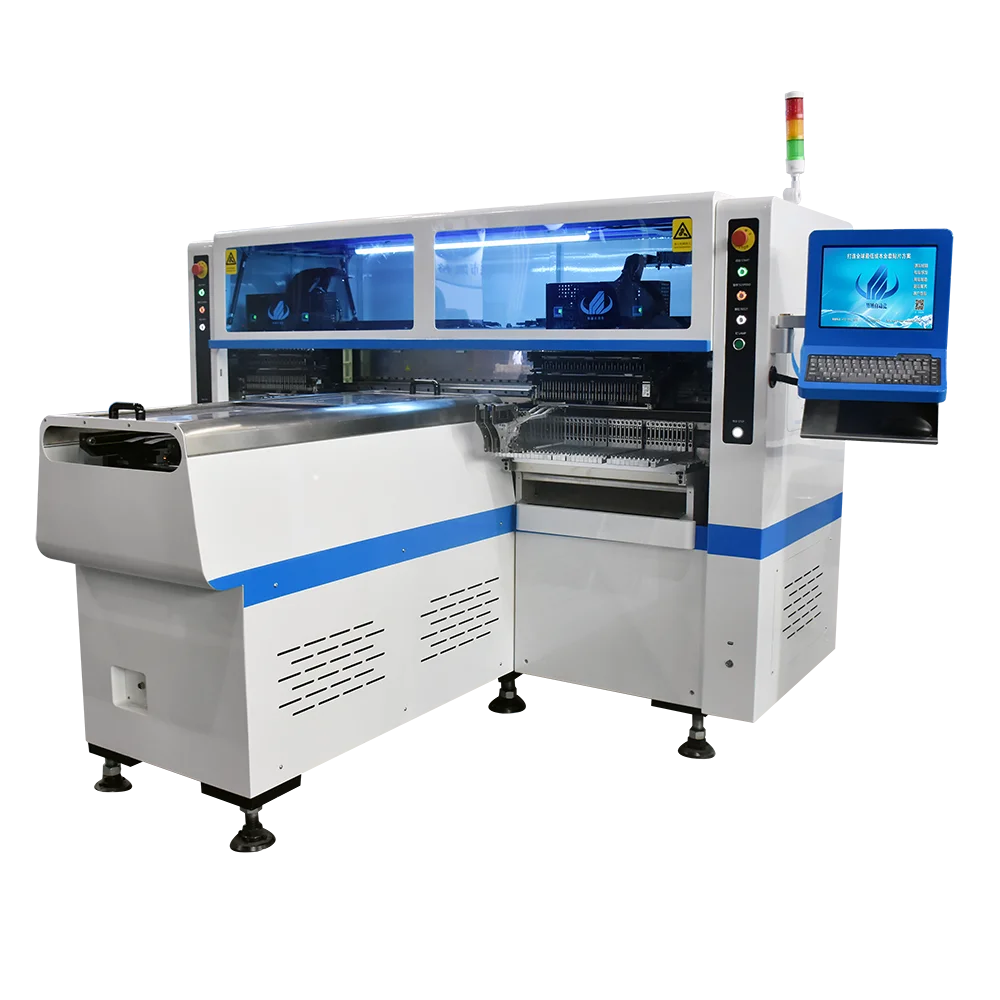

Configure the world famous grating ruler, achieving high precision motion control.

Using imported precision square rail, effectively improve the placement accuracy.

Using a unique high-definition optical prism industrial cameras to complete mount high-precision components.

With the vision position system, can automatically identify the MARK point, effectively improve SMT production efficiency and placement accuracy.

automatic visional programming, it is no need to input the coordinates of components by manual, programming is simple, easy to learn for beginners and it is convenient and practica, it is most suitable for mass production in middle scale.

The placement configure 10 nozzles.

Cost-effective automatic placement machine, it is most suitable for mass production in middle scale and , high quality usage.

The placement configure a set of PCB board transport system, it can seamless connection with stencil printer , handplace desk and reflow oven.

Features

1.effectively guarantee the reliability and stability of the placement machine use for a long time.

2. The whole machine adopts precision guide rail, improve the SMT precision.

3. The whole machine adopts high-definition industrial camera, complete visual para pasted on high precision components.

4. Configuration, SMT machine vision system can automatically identify the MARK point,

improve the efficiency and SMT placement machine production precision effectively.

5. Can be automatically visual programmingProgramming is simple, convenient and even beginner is convenient and practical.

6. The machine configuration five suction nozzle. Can prompt by software manual to replace the suction nozzle.

7. Cost-effective automatic placement machine, the most suitable for small and medium scale production,

scientific research and personal use.

|

PCB |

PCB length width |

Max:400*350mm min:50*50mm |

|

PCB thickness |

0.1~6mm |

|

|

PCB clamping |

Electric clamping |

|

|

Mounting mode |

ØGroup to pick and separate to place ØSeparate to pick and separate to place |

|

|

O.S. |

system |

Windows 7 |

|

software |

R&D independently |

|

|

display |

Touch screen monitor |

|

|

Input device |

Keyboard , mouse |

|

|

Vision system |

No.of camera |

2 sets of imported camera Vision alignment ,mark correction |

|

Mounting precision |

0.02mm(repeat precision) |

|

|

Mounting height |

<25mm |

|

|

Mounting speed |

30000~35000CPH |

|

|

Components space |

0.2mm |

|

|

Power |

380AC 50HZ |

|

|

Power consumption |

6KW |

|

|

Conveyor transmission |

Max length:500mm |

|

|

Transmission speed |

>1500mm/sec |

|

|

Transmission direction |

Single |

|

|

Transmission mode |

Auto online drive |

|

|

Air pressure |

>5.0kg /cm² |

|

|

Electrical control |

Independent research and development by ETON |

|

|

X,Y,X axis drive way |

Servo motor control for X,Y,Z axis |

|

|

Feeding way |

|

|

|

Feeding system |

No.of feeders station |

26 PCS |

|

No.of nozzles |

8 PCS |

|

|

Feeding way |

Electric feeder with double motor |

|

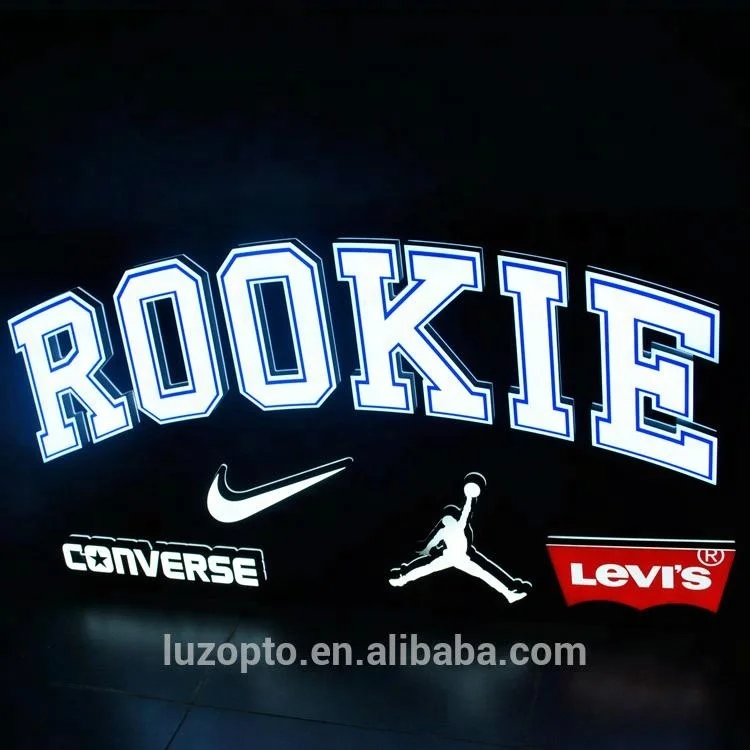

Applications

Shenzhen Eton Automation Equipment Co.,Ltd.is a national high-tech enterprise which specilizes in automatic high-speed SMT pick ahd place machines for costomers,combining R&D,production,sales and service as one

Rapidly evolving market forces driving towards energy efficiency and eco-friendliness,alone with exciting technological advances,are driving the evolution of the lighting industry forward,providing greater opportunities and growing challenges.

Our Projects

Our Teams

Our Clients

Our mode of transportation including water, land and air transportation.You can choose the most suitable way according to your requirements.

Our packing is made of wooden box with vacuum package, and we promise to deliver the goods within four weeks after payment.

Certificate of Honor

ETON advanced technology and innovation drives the revolution of market rapidly ,and obtains a number of intellectual property technologies.and rated as “shenzhen high-tech enterprise” “china high-tech enterprise” “shenzhen top brand” “2015 LED technology innovation award” “the 4th China LED first innovation award”.

we will send our engineer to your factory to install machine and training freely.

We have service office in india,and have indian engineer in delhi and mumbai.Can support quickly.

Standard warranty is one year,during warranty,any parts need to be repaired and replaced will be free.

Attention

1. Before using the Pick and Place machine, you must understand the basic parameters of the placement machine;

2. Before running the Pick and Place machine, the operator should do a comprehensive inspection of the machine.

3. According to the boot operation sequence to implement the Pick and Place machine, there must have a detailed machine operation instructions;

4. It is necessary to conduct regular troubleshooting and maintenance work on the Pick and Place machine in a timely manner.

Remarks

1.Payment terms: Deposit 30% in advance,the balance 70% should be paid before shipment by T/T.

2.Delivery time: 30 days after deposit.

3.Warranty: 1 year.(including spare parts)

1.Choose which mode of transportation?

Our modes of transportation are flexible, including water, land and air transportation.

2.Do you have oversea after sale service?

We can offer technical support abroad. If you have any technical problem, our engineers will support you promptly.

3.What is the delivery date?

We will deliver the goods after 30 days' deposit.

4. Is this machine easy to operate?

Of course, the operating system supports Chinese-English interface display, easy to understand and operate.

5.Why choose us?

Leading SMT Supplier in China;In the LED industry market share is in an absolute leading position.

Contact me

Share

Share

Customer Reviews total 0 items